Purple inorganic pigment based on Mg3TeO6 structure and preparation method and application thereof

An inorganic pigment, purple technology, applied in the direction of inorganic chemistry, chemical instruments and methods, selenium/tellurium compounds, etc., can solve the problems of poor acid and alkali resistance, high temperature resistance, etc., achieve non-toxic raw materials, keep color unchanged, raw materials parity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

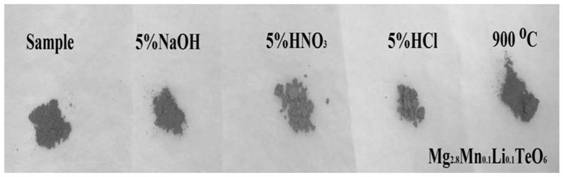

Embodiment 1

[0028] The raw material MgO, TeO 2 , MnCO 3 , Li 2 CO 3 According to the elemental molar ratio Mg:Te:Mn:Li=2.8:1:0.1:0.1, weigh it, mix and grind it evenly, put it into the muffle furnace, raise the temperature from room temperature to 800°C at a heating rate of 4°C / min, in the air Calcined in medium for 6 hours, cooled naturally, and the sample was obtained after grinding.

Embodiment 2

[0030] The raw material MgCO 3 , Te(OH) 6 , MnO, Li 2 CO 3 Weigh it according to the elemental molar ratio Mg:Te:Mn:Li=2.9:1:0.05:0.05, mix and grind evenly, put it into a muffle furnace, raise the temperature from room temperature to 750°C at a rate of 2°C / min, in air Calcined in medium for 6 hours, cooled naturally, and the sample was obtained after grinding.

Embodiment 3

[0032] The raw material MgO, TeO 2 , MnCO 3 , Li 2 CO 3 According to the elemental molar ratio Mg:Te:Mn:Li=2.7:1:0.15:0.15, weighed, mixed and ground evenly into the muffle furnace, from room temperature to 850°C at a heating rate of 4°C / min, in the air Calcined in medium for 12 hours, cooled naturally, and the sample was obtained after grinding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com