Heat resisting device for copper part welding

A technology of heat resistance and copper parts, applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., to achieve the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

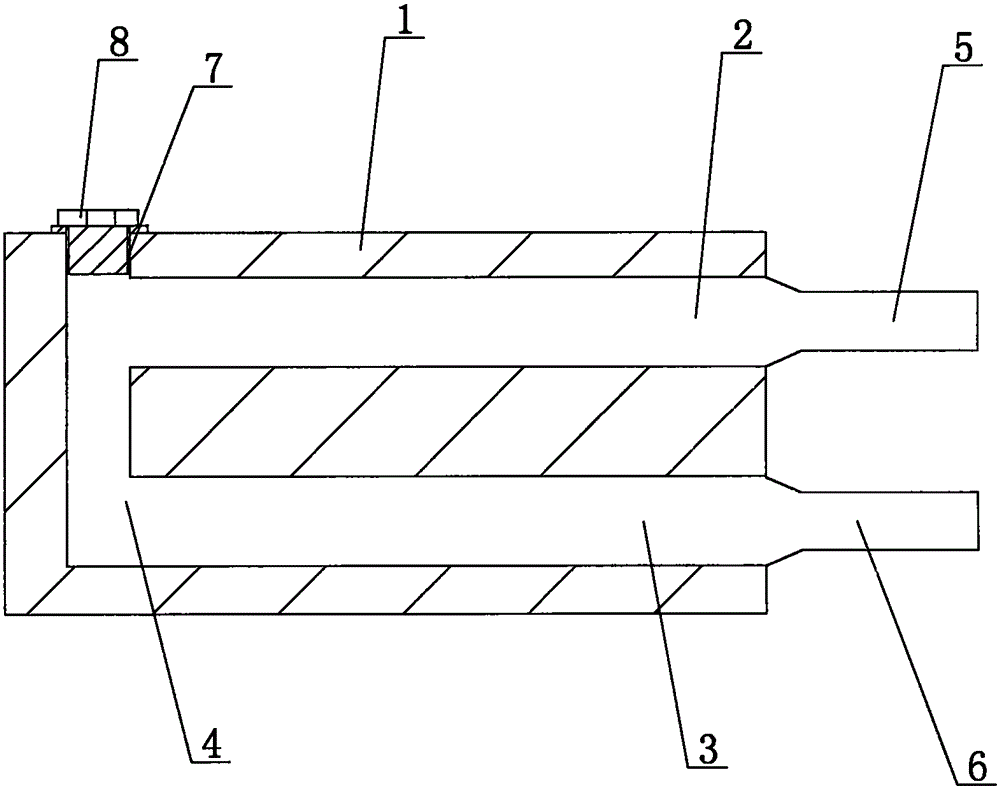

[0015] see figure 1 as shown, figure 1 It is a cross-sectional view of the splint of the heat resistance device for welding copper parts provided in Embodiment 1 of the present invention.

[0016] In this embodiment, a heat resistance device for welding copper parts includes two splints 1 with the same structure, and one end of the splint 1 is separated with a water inlet 2 and a water outlet 3, and the water inlet 2 and the water outlet 3 are communicated through the cooling water channel 4 opened in the splint 1, and the water inlet 2 and the water outlet 3 are welded with a water inlet 5 and a water outlet 6, so that they can be connected to the cooling water when they are ready for use. Yes, the cross-section of the cooling water channel 4 has a "匚"-shaped structure, and a channel processing h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com