Clamping tool and method for adhesive connection of metal bipolar plates of fuel cells

A metal bipolar plate and fuel cell technology, applied in the field of fixtures, can solve the problems of increasing the difficulty of surface coating preparation, virtual welding, low efficiency, etc., to simplify the initial clamping process, avoid warping deformation, simplify the The effect of the overall process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can more clearly understand how to practice the present invention. While the invention has been described in connection with preferred specific embodiments thereof, these embodiments are illustrative only and are not intended to limit the scope of the invention.

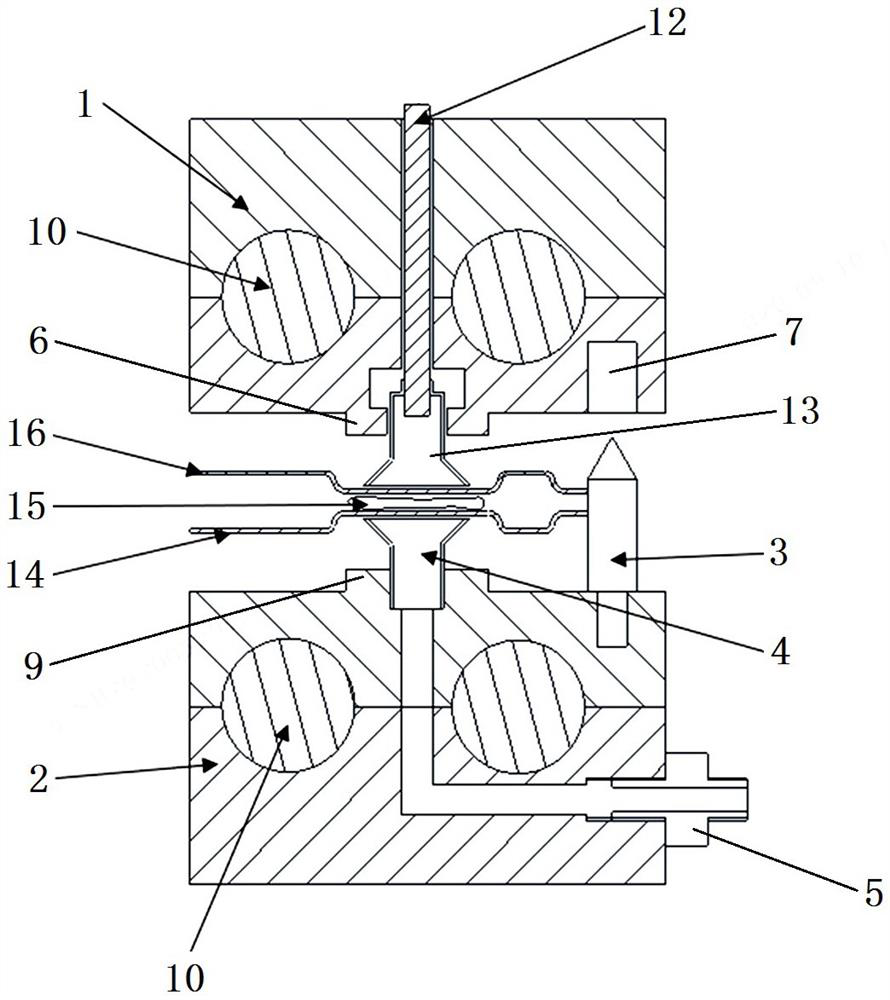

[0048] A clamping tool for adhesive connection of metal bipolar plates of a fuel cell comprises a positioning device, a heating device and a vibration device.

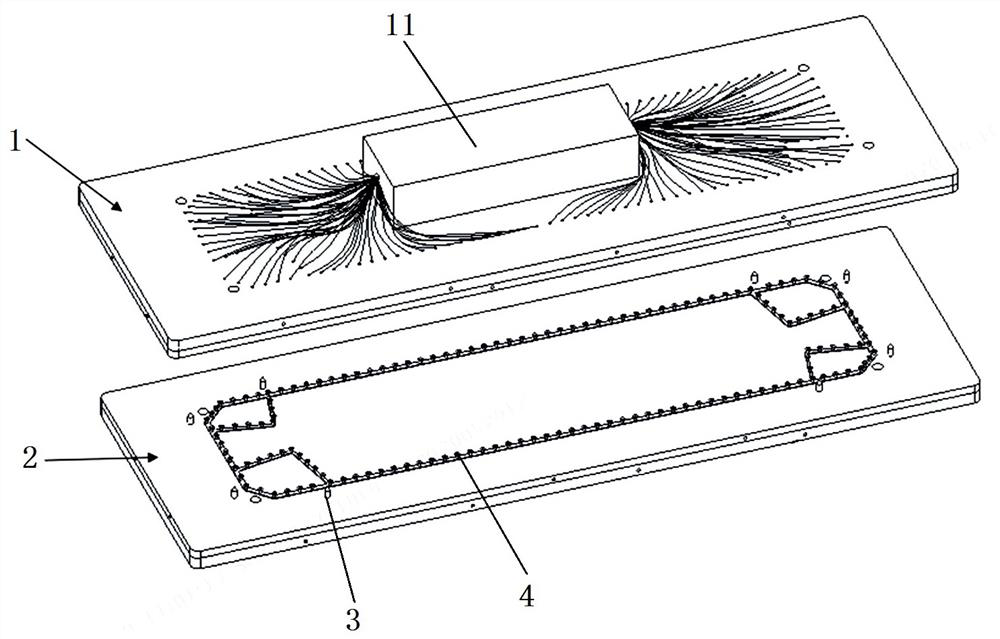

[0049] The positioning device is used to fix the posture of the polar plate. see figure 1 with figure 2 , The positioning device mainly includes a tooling upper cover plate 1, a tooling lower plate 2, a positioning pin 3, a first suction nozzle 4, a gas pipe joint 5, and a vacuum pump.

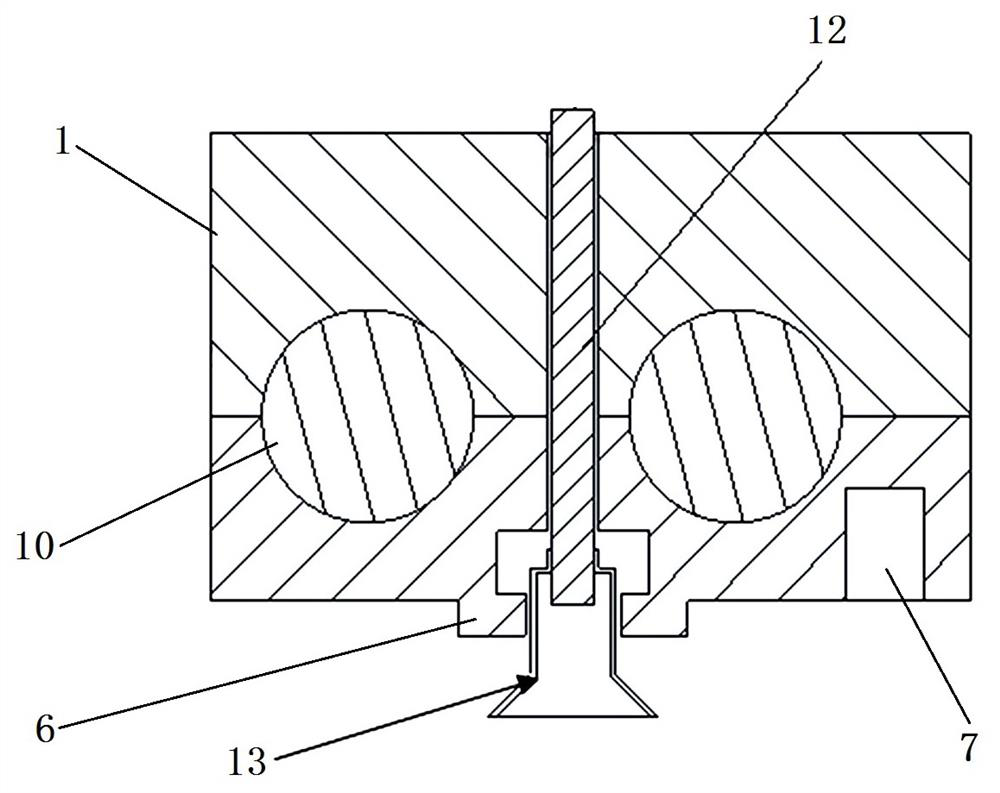

[0050] see image 3 The tooling upper cover plate 1 is formed by connecting two first tooling plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com