Scratch-resistant sound-insulating leather wallboard

A scratch-resistant, leather-based technology, applied in the field of sheet metal manufacturing, which can solve problems such as difficulty in meeting practical application requirements, low areal density and elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

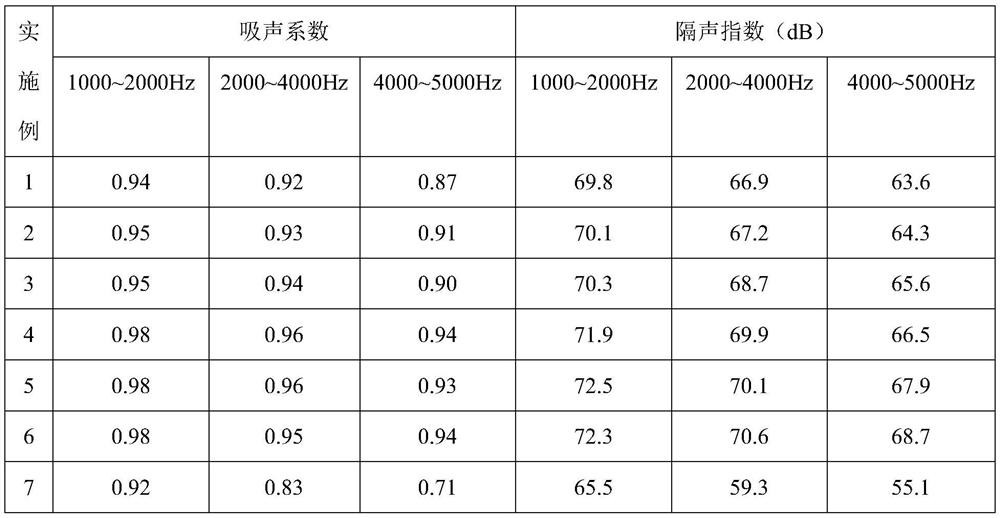

Examples

Embodiment 1

[0026] Example 1: A scratch-resistant and sound-insulating leather wallboard, which includes, from top to bottom, scratch-resistant flexible leather weaving cloth, PVC sheet A, polymer sound-insulating felt, PVC sheet B and mute mat; PVC sheet A and PVC sheet B is a stone-plastic plate, in which the mass ratio of PVC powder and calcium powder is 1:2.5 to 1:3.3.

[0027] Its preparation method comprises the following steps:

[0028] S1. Preparation of scratch-resistant flexible plywood fabric, three-layer coating on the surface of the sandwich cloth: primer layer, middle-coat foam layer, and top-coat scratch-resistant layer;

[0029] S2. The preparation of PVC sheet material A and PVC sheet material B, adopts twin-screw extruder to produce the PVC sheet material A and PVC sheet material B that thickness is 2~5mm;

[0030] S3. Lay the scratch-resistant flexible leather textured cloth, PVC sheet A, polymer sound insulation felt, PVC sheet B and mute mat in sequence, and stick th...

Embodiment 2

[0031] Example 2: A scratch-resistant and sound-insulating leather wallboard, which includes, from top to bottom, scratch-resistant flexible leather weaving cloth, PVC sheet A, polymer sound-insulating felt, PVC sheet B and mute mat; PVC sheet A and PVC sheet B is a stone-plastic plate, in which the mass ratio of PVC powder and calcium powder is 1:2.5.

[0032] Its preparation method comprises the following steps:

[0033] S1. Preparation of scratch-resistant flexible leather lattice fabric, the surface of the sandwich cloth is coated with three layers: base coat, middle coat foam layer, top coat scratch-resistant layer; base coat: penetrate into the sandwich cloth, increase The adhesion between the sandwich cloth and the middle foam layer, the thickness is 0.1~0.2mm; the middle foam layer: use polyurethane resin, add foaming agent, the material foams slightly during the molding process, so that the whole material has good elasticity, The thickness is 0.5-0.7mm; surface coati...

Embodiment 3

[0036]Example 3: A scratch-resistant and sound-insulating leather wallboard, comprising, from top to bottom, scratch-resistant flexible leather weaving cloth, PVC sheet A, polymer sound-insulating felt, PVC sheet B and mute mat; PVC sheet A and PVC sheet B is a stone-plastic plate, in which the mass ratio of PVC powder and calcium powder is 1:3.3.

[0037] Its preparation method comprises the following steps:

[0038] S1. Preparation of scratch-resistant flexible leather lattice fabric, the surface of the sandwich cloth is coated with three layers: base coat, middle coat foam layer, top coat scratch-resistant layer; base coat: penetrate into the sandwich cloth, increase The adhesion between the sandwich cloth and the middle foam layer, the thickness is 0.1~0.2mm; the middle foam layer: use polyurethane resin, add foaming agent, the material foams slightly during the molding process, so that the whole material has good elasticity, The thickness is 0.5-0.7mm; surface coating sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com