Non-amine asphalt anti-stripping agent and preparation method thereof

An anti-stripping agent, non-amine technology, applied in the field of non-amine asphalt anti-stripping agent and its preparation, can solve the problems of poor anti-ultraviolet aging performance and large environmental pollution, so as to improve adhesion and prolong service life , Improve the effect of anti-ultraviolet aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

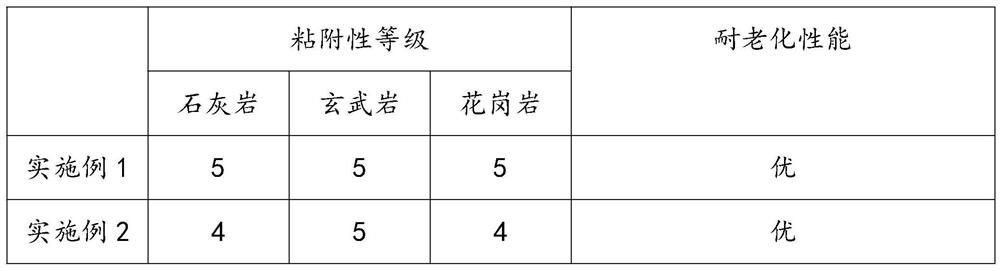

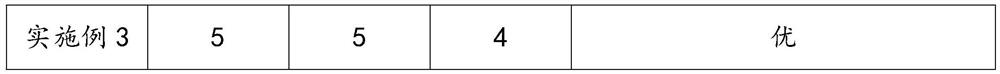

Examples

Embodiment 1

[0023] A non-amine asphalt anti-stripping agent, comprising the following components: paraffin wax, oleic acid, sodium lauryl phosphate, molecular sieve and silane.

[0024] In this embodiment, an antioxidant is also included.

[0025] In this embodiment, phosphorus pentoxide is also included.

[0026] In this embodiment, manganese dioxide is also included.

[0027] In this embodiment, the silanes include long-chain organosilanes and aminosilanes.

[0028] In the present embodiment, the parts by weight of each component are as follows: 55 parts of paraffin, 25 parts of oleic acid, 25 parts of sodium lauryl phosphate, 55 parts of molecular sieves, 5 parts of long-chain organosilane, 5 parts of aminosilane, 7 parts of antioxidant, 3 parts of phosphorus pentoxide and 2 parts of manganese dioxide.

[0029] The preparation method of above-mentioned non-amine asphalt antistripping agent is as follows, comprises the following steps:

[0030] S1. Dissolve molecular sieves in organ...

Embodiment 2

[0035] The composition and preparation method of the formula described in this example and Example 1 are the same, the difference is that the parts by weight of each component in this example are as follows: 50 parts of paraffin, 20 parts of oleic acid, dodecyl phosphoric acid 20 parts of sodium ester, 50 parts of molecular sieve, 4 parts of long-chain organosilane, 3 parts of aminosilane, 4 parts of antioxidant, 2 parts of phosphorus pentoxide and 1 part of manganese dioxide.

Embodiment 3

[0037] The composition and preparation method of the formula described in this example and Example 1 are the same, the difference is that the parts by weight of each component in this example are as follows: 60 parts of paraffin, 30 parts of oleic acid, dodecyl phosphoric acid 30 parts of sodium ester, 60 parts of molecular sieve, 6 parts of long-chain organosilane, 7 parts of aminosilane, 10 parts of antioxidant, 4 parts of phosphorus pentoxide and 3 parts of manganese dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com