Light high-specific-strength high-entropy alloy material and preparation method thereof

A technology of high-entropy alloys and high specific strength, applied in the field of alloy materials, can solve the problems of limited application range and high density of high-entropy alloys, achieve high service temperature, low-cost price advantages, and facilitate large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

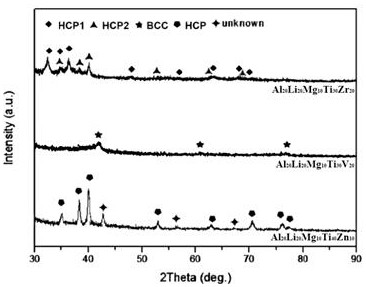

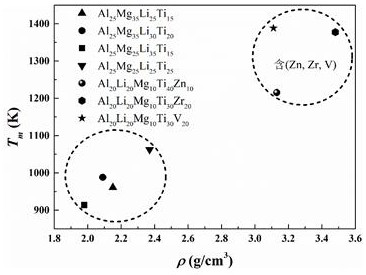

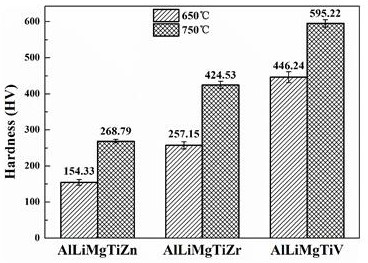

[0033] Example 1: Preparation of light-weight and high-specific-strength high-entropy alloy Al 20 Li 20 Mg 10 Ti 40 Zn 10 high entropy alloy high entropy alloy material

[0034] (1) Al:Li=2:1 (at.%) aluminum-lithium alloy powder, Mg:Li=1:1 (at.%) magnesium-lithium alloy powder and 325 mesh Ti and Zn alloy powder are used Prepare Al according to atomic percentage in vacuum glove box 20 Li 20 Mg 10 Ti 40 Zn 10 Element.

[0035] (2) Pour the weighed alloying element powder into the stainless steel ball mill tank matched with the ball mill and mix evenly. In order to prevent the alloy powder from agglomerating and agglomerating or sticking to the wall of the ball milling tank during the mechanical alloying process, resulting in low powder yield and even insufficient alloying process, 3 wt.% stearic acid ( C 18 h 36 o 2 ) as a process control agent. The ball milling medium adopts stainless steel balls, and the ball-to-material ratio is 10:1.

[0036] (3) Put the bal...

Embodiment 2

[0041] Embodiment 2: Preparation of high-entropy alloy Al with light weight and high specific strength 20 Li 20 Mg 10 Ti3 0 Zr 20 high entropy alloy high entropy alloy material

[0042] (1) Use Al:Li = 2:1 (at.%) aluminum-lithium master alloy powder, Mg:Li = 1:1 (at.%) magnesium-lithium master alloy powder and 325 mesh Ti and Zr alloy powder Prepare Al according to atomic percentage in vacuum glove box 20 Li 20 Mg 10 Ti3 0 Zr 20 .

[0043] (2) Pour the weighed alloying element powder into the stainless steel ball mill tank matched with the ball mill and mix evenly. In order to prevent the alloy powder from agglomerating and agglomerating or sticking to the wall of the ball milling tank during the mechanical alloying process, resulting in low powder yield and even insufficient alloying process, 3 wt.% stearic acid ( C 18 h 36 o 2 ) as a process control agent. The ball milling medium adopts stainless steel balls, and the ball-to-material ratio is 10:1.

[0044] (...

Embodiment 3

[0049] Example 3: Preparation of light-weight, high-specific-strength high-entropy alloy Al 20 Li 20 Mg 10 Ti 30 V 20 high entropy alloy high entropy alloy material

[0050] (1) Use Al:Li=2:1 (at.%) aluminum-lithium alloy powder, Mg:Li=1:1 (at.%) magnesium-lithium alloy powder and 325 mesh Ti and Zr alloy powder Prepare Al according to atomic percentage in vacuum glove box 20 Li 20 Mg 10 Ti 30 V 20 .

[0051] (2) Pour the weighed alloying element powder into the stainless steel ball mill tank matched with the ball mill and mix evenly. In order to prevent the alloy powder from agglomerating and agglomerating or sticking to the wall of the ball milling tank during the mechanical alloying process, resulting in low powder yield and even insufficient alloying process, 3 wt.% stearic acid ( C 18 h 36 o 2 ) as a process control agent. The ball milling medium adopts stainless steel balls, and the ball-to-material ratio is 10:1.

[0052] (3) Put the ball milling medium,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific strength | aaaaa | aaaaa |

| Specific strength | aaaaa | aaaaa |

| Specific strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com