Method for producing waste plastic oil through normal-pressure hydrofining

A production method and technology for waste plastics, which are applied in the refining of hydrocarbon oil, petroleum industry, and processing of hydrocarbon oil, etc., can solve the problems of plastic coking, difficult to achieve clean production, complex process flow, etc. The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

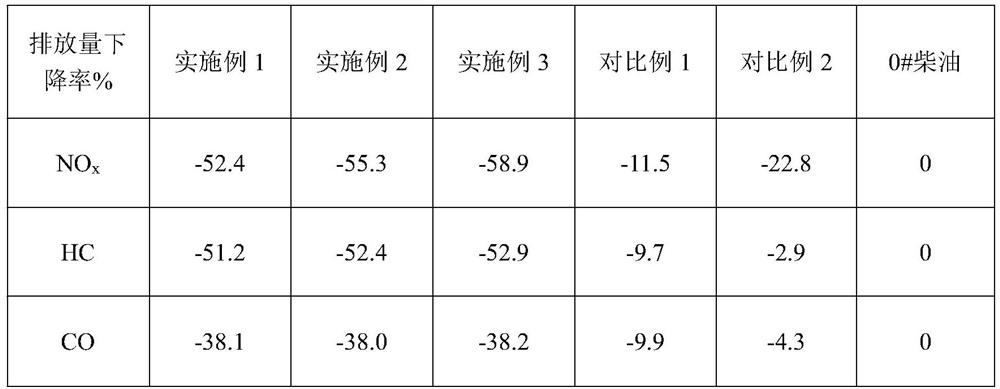

Embodiment 1

[0025] Add waste plastic oil in the normal pressure reactor, then add the catalyst according to 1.3% of the total weight of the waste plastic oil and fully stir and mix, then feed hydrogen relative to the supersaturation of the waste plastic oil, and then at 1 atmospheric pressure and 350 ° C A heterogeneous catalytic reaction occurs under the conditions, and the reaction time is 10s to obtain hydrogenated ether hydrocarbon fuel.

Embodiment 2

[0027] Add waste plastic oil in the normal pressure reactor, then add the catalyst according to 1.5% of the total weight of the waste plastic oil and fully stir and mix, then feed hydrogen relative to the supersaturation of the waste plastic oil, and then at 1 atmospheric pressure and 370 ° C A heterogeneous catalytic reaction occurs under the conditions, and the reaction time is 20s, and hydrogenated ether hydrocarbon fuel is obtained.

Embodiment 3

[0029] Add waste plastic oil in the normal pressure reactor, then add the catalyst according to 1.0% of the total weight of the waste plastic oil and fully stir and mix, then feed hydrogen relative to the supersaturation of the waste plastic oil, and then at 1 atmospheric pressure and 400 ° C A heterogeneous catalytic reaction occurs under the conditions, and the reaction time is 15s to obtain hydrogenated ether hydrocarbon fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com