System and method for harmlessly treating sludge

A flue gas treatment system and sludge technology, applied in the direction of combustion methods, incinerators, lighting and heating equipment, etc., can solve the problems of high investment and operation costs, complex sludge treatment system, etc., achieve good flue gas emission indicators, improve Waste heat utilization rate, VOC removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

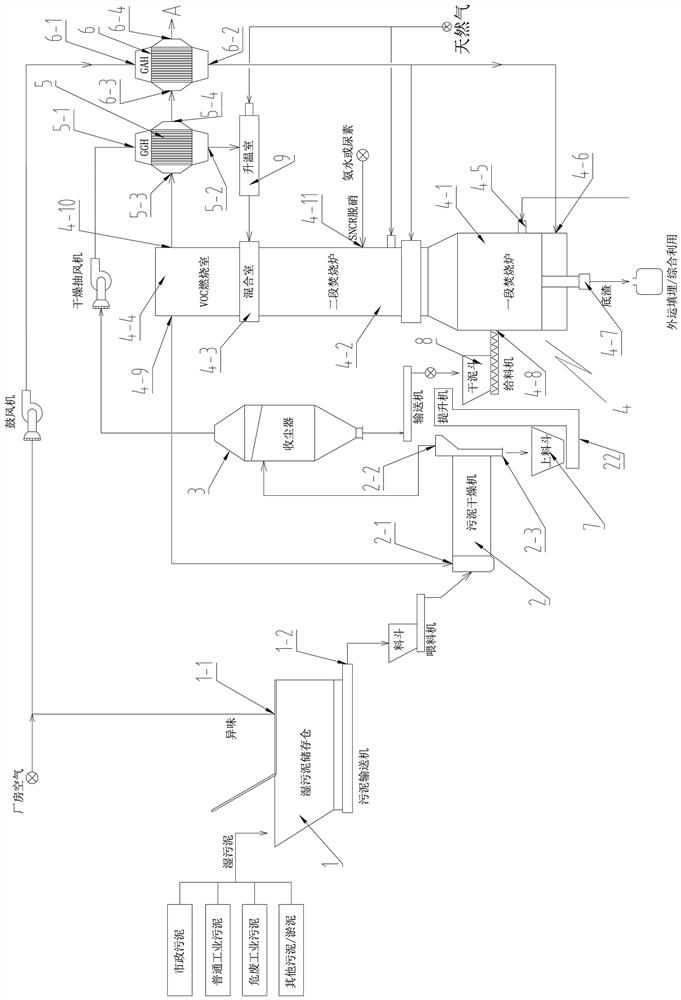

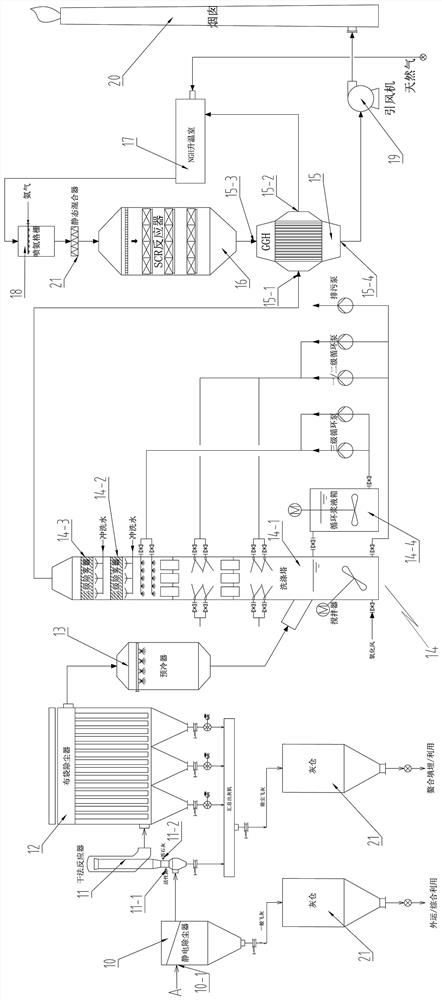

[0043] A system for harmless disposal of sludge according to the present invention, which includes a sludge storage bin 1, a sludge dryer 2, an integrated incinerator 4, and a flue gas treatment system; the integrated incinerator 4 and the flue gas treatment system pass through The heat exchange equipment is connected; the heat exchange equipment includes the first GGH (Gas Gas Heater) heat exchanger 5 and the GAH (Gas air heater) heat exchanger 6 connected to each other, the first GGH heat exchanger 5 and the GAH heat exchanger 6 are all It is based on the flue gas / flue gas heat exchange principle to realize the reuse of thermal energy. Wet sludge from municipal sludge system, general industrial sludge system, hazardous waste industrial sludge system, and other sludge systems can be harmlessly treated by this patented technical solution.

[0044] Such as figure 1As shown, the integrated incinerator 4 is provided with interconnected combustion chamber 4-4, mixing chamber 4-3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com