Electrically controlled high-pressure fuel injector for realizing quick fuel cut

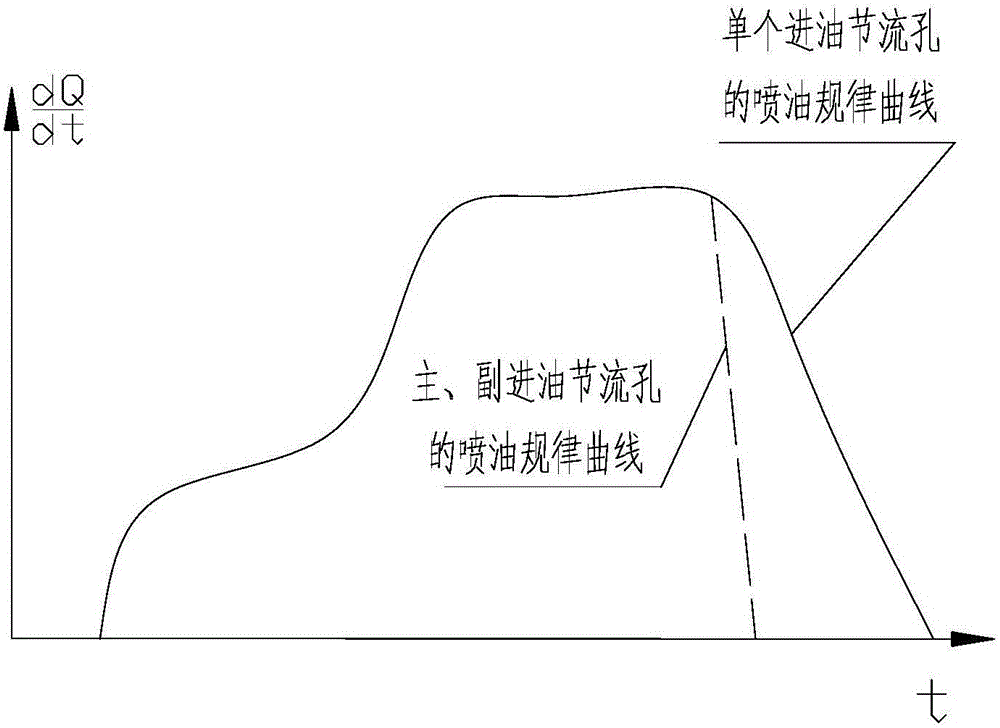

A high-pressure fuel injection and fuel injector technology, which is applied to machines/engines, fuel injection devices, engine components, etc., can solve problems such as economic deterioration, shortened afterburning, and harmful emissions of soot, and achieve improved economy and emissions. Indicator, afterburn suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be further described below with reference to the accompanying drawings. It should be understood, however, that these descriptions are exemplary only and are not intended to limit the scope of the invention.

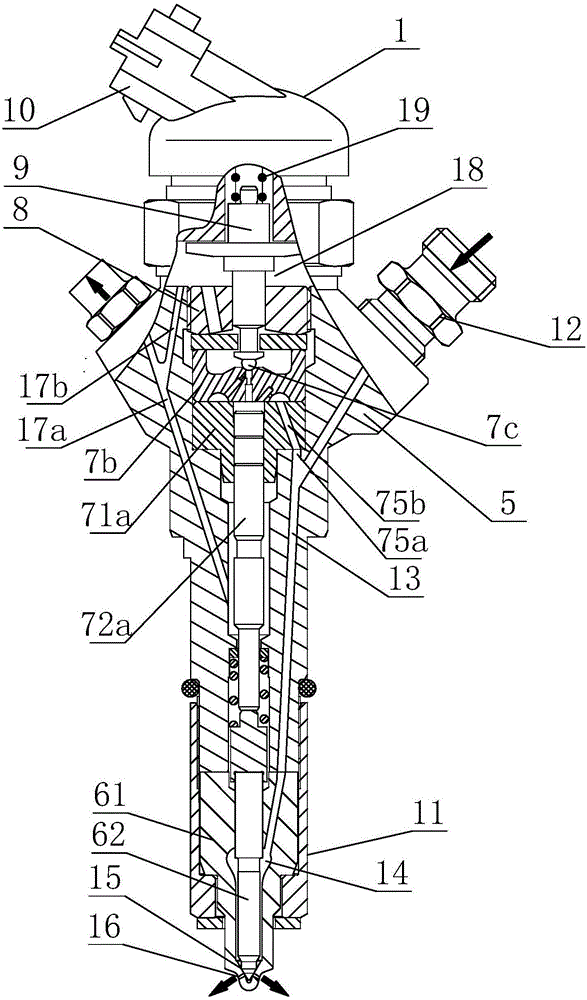

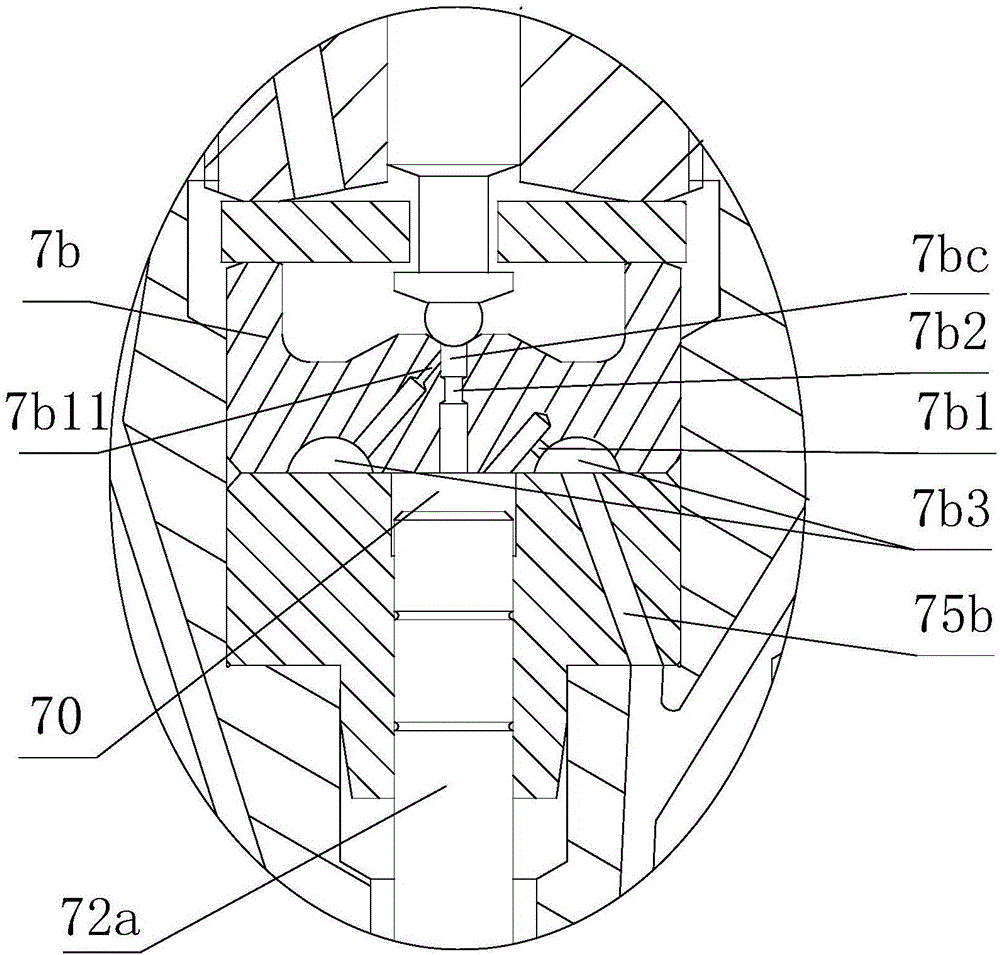

[0029] In order to explain this invention in detail, it demonstrates referring drawings. figure 1 is a schematic cross-sectional view of the first embodiment of the electronically controlled high-pressure fuel injector of the present invention, figure 2 yes figure 1 The enlarged view of the main part.

[0030] In this application, the electromagnet 10 side of the electronically controlled high-pressure fuel injector 1 ( figure 1 and figure 2 The upper side) is called the upper side, and the nozzle hole 16 side ( figure 1 and figure 2 The lower side) is called the lower side, however, this is only a definition for the convenience of explanation, and does not represent the real installation direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com