Optional tooth difference swing type high-rotation-speed internal-combustion engine

A swing type, internal combustion engine technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of shortened life of internal combustion engines, complex structure, large vibration, etc., and achieve the effect of compact structure

Inactive Publication Date: 2013-04-24

SICHUAN UNIV

View PDF6 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Because this type of internal combustion engine relies on the linear motion of the piston and the plane motion of the connecting rod to press and drive the crankshaft to rotate, resulting in a large friction between the motion pairs, resulting in low transmission efficiency of the internal combustion engine

These existing crankshaft connecting rod type internal combustion engines also have the following main disadvantages: large volume; the unbalanced centrifugal force on the connecting rod and the crankshaft is relatively large; the impact is large and the vibration is large; and thus cause large mechanical wear and shorten the life of the internal combustion engine; The structure is complex, and processing, manufacturing, and assembly are relatively difficult; in addition, the general internal combustion engine and the transmission device are two independent machines, and usually the internal combustion engine needs to install an additional transmission for subsequent speed change, resulting in a large volume

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

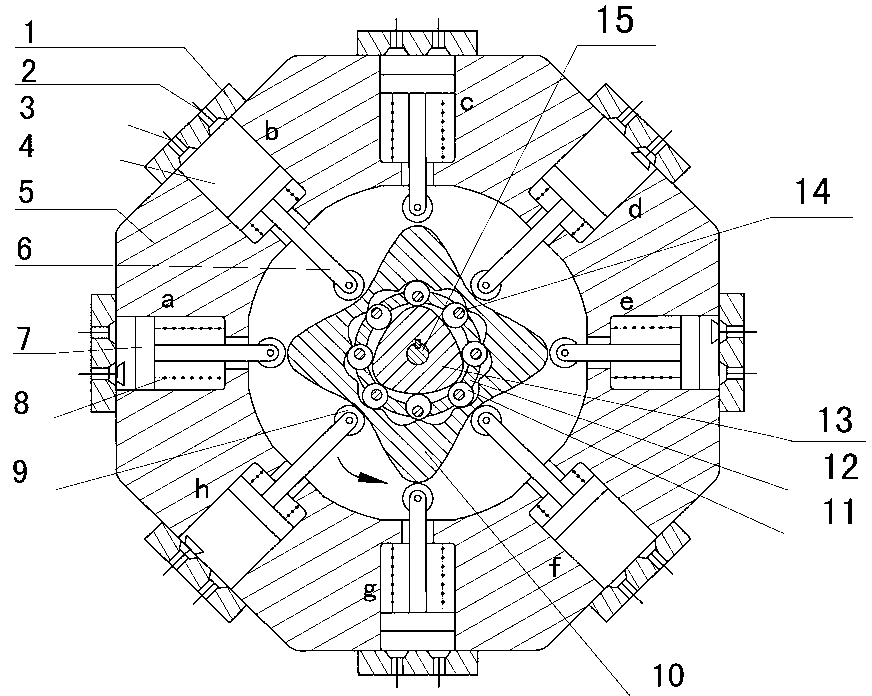

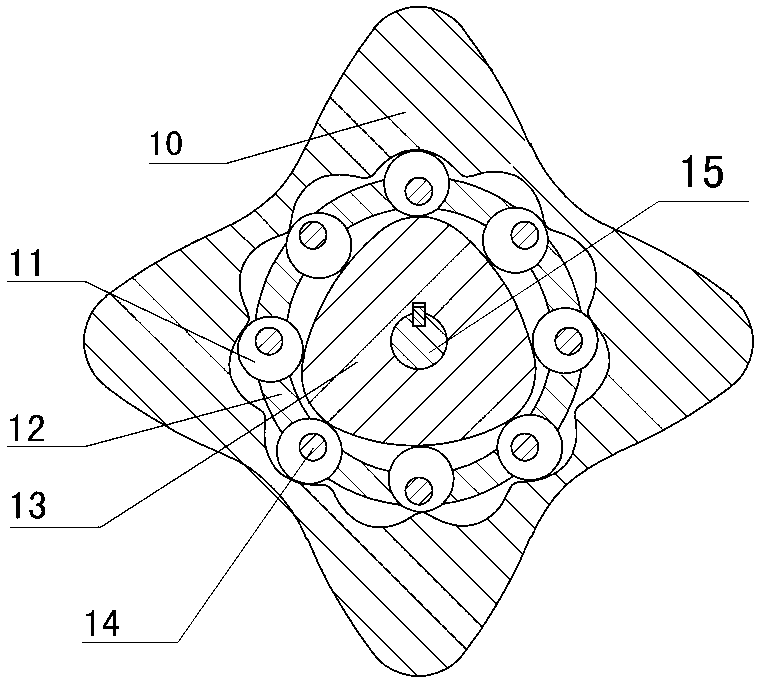

An optional tooth difference swing type high-rotation-speed internal-combustion engine relates to the field of gas power. The tooth difference swing type high-rotation-speed internal-combustion engine is characterized in that eight air cylinders are annularly evenly distributed on the periphery of a protruding inner gear ring to allow resultant force borne by the inner gear ring to be zero. An air cylinder piston directly acts on the protruding inner gear ring through a push rod. Power is transmitted by protruding inner gear ring to an output shaft connected with a multi-phase shock wave wheel key through transmission of a multi-phase cam swing movable tooth. A connecting rod and a crankshaft in traditional internal-combustion engines are omitted, and the protruding inner multi-phase cam swing transmission mechanism has no eccentric weight, and has the advantages that self-balancing of inertia force and work load. Rotation speed of the output shafts depends on transmission ratio of movable tooth transmission. If a movable tooth frame is fixed, high-speed output of the multi-phase shock wave wheel is achieved. The internal-combustion engine is widely applicable to fields, which need high rotation speed, such as helicopter engines and small power generators. When rotation speed is fixed, emission of harmful gas can be reduced. The internal-combustion engine is simple and compact in structure, low in axial size, self-balancing in stress, and stable in operation.

Description

technical field [0001] The invention relates to the field of gas power, more specifically, a swing type high-speed internal combustion engine with any number of tooth differences. Background technique [0002] At present, a general internal combustion engine (engine) is composed of a body, a crank connecting rod mechanism, a gas distribution mechanism, a cooling system, a lubrication system, a fuel system, and an ignition system. stroke. The transmission mechanism of this type of internal combustion engine uses a crank-connecting rod mechanism, which transmits the power of the piston to the crankshaft through the connecting rod, and converts the reciprocating linear motion of the piston into the rotary motion of the crankshaft. Because this type of internal combustion engine presses and drives the crankshaft to rotate by the linear motion of the piston and the planar motion of the connecting rod, there is greater friction between the kinematic pairs, resulting in low trans...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F02B75/22F02B75/40

Inventor 梁尚明贺飞飞赵纯可

Owner SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com