Water-based aircraft paint remover and preparation method thereof

A paint stripper, aircraft technology, used in chemical paint/ink removers, coatings, etc., can solve problems such as toxicity, operator health hazards, environmental pollution, etc., achieve low volatilization loss, improve paint stripping efficiency, The effect of high paint stripping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

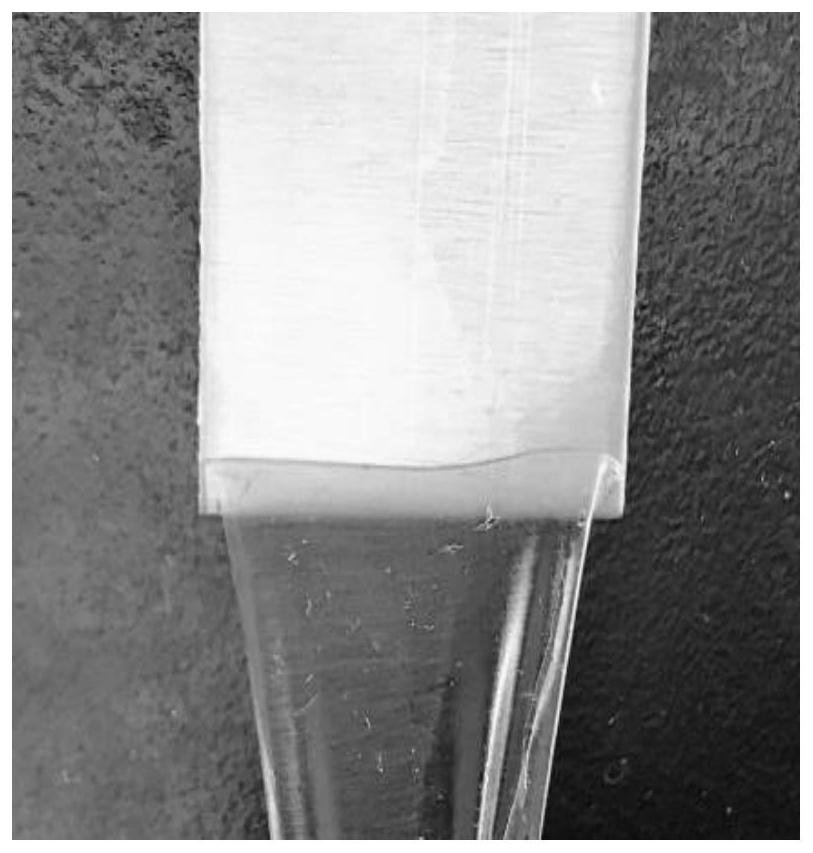

Image

Examples

Embodiment 1

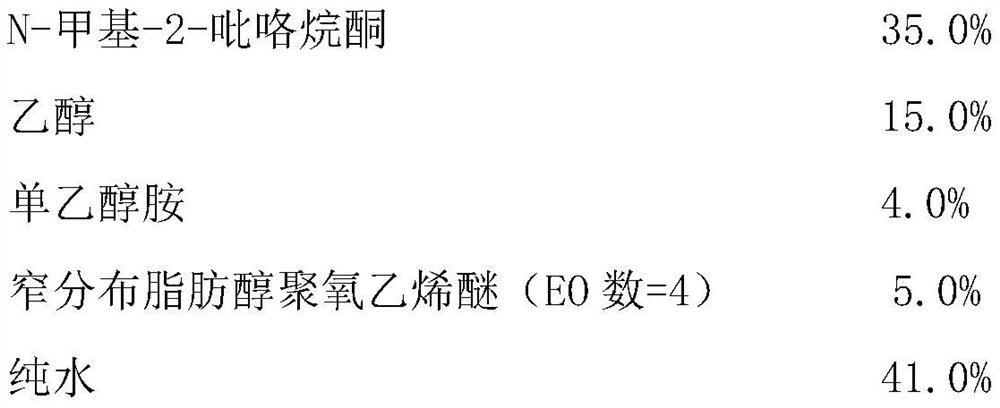

[0026] Present embodiment relates to a kind of water-based aircraft paint remover, the component that comprises and mass ratio thereof are:

[0027]

Embodiment 2

[0029] Present embodiment relates to a kind of water-based aircraft paint remover, the component that comprises and mass ratio thereof are:

[0030]

Embodiment 3

[0032] Present embodiment relates to a kind of water-based aircraft paint remover, the component that comprises and mass ratio thereof are:

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com