A kind of anticorrosion and antirust paint and preparation method thereof

An anti-rust paint and corrosion-resistant technology, applied in the field of coatings, can solve the problems of poor adhesion and poor corrosion resistance of anti-rust paint, and achieve the effects of enhancing adhesion, reducing hydrophobicity, and inhibiting the formation of rust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

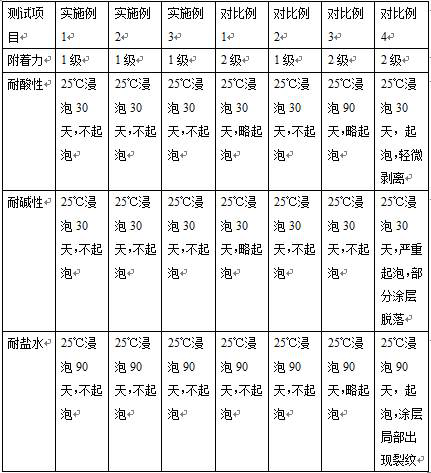

Examples

preparation example Construction

[0027] A preparation method for corrosion-resistant antirust paint, comprising the steps of:

[0028] Take the anti-rust active material and add the curing agent according to the mass ratio of 2~5:10~20, stir and mix at 50~60°C for 3~5h to obtain the mixed matrix, and take 200~300 parts of the mixed matrix, 30~50 parts of preservative additives, 5~10 parts of titanium dioxide, 2~7 parts of talc, 8~15 parts of lecithin, 8~13 parts of hydrogenated castor oil, 7~12 parts of glass flakes, 3~6 parts of γ -Aminopropyltriethoxysilane, 80~150 parts of water, stirred and mixed at 60~70°C for 40~50 minutes to obtain corrosion-resistant and anti-rust paint.

Embodiment 1

[0030] Anti-rust active substance: take dogwood seed shells and crush them through a 40-mesh sieve, collect the sieved particles, take the sieved particles and add distilled water at a mass ratio of 1:10, then add 40% of the mass fraction of distilled water to be 25% hydroxymethyl sulfonate Sodium acid solution, keep warm at 75°C for 4h, filter, take the filtrate to rotary evaporate, concentrate to 20 degrees Baume to get the concentrate, take the concentrate and mix it with polyvinyl butyral at a mass ratio of 3:6 to get the mixture, take Add acetone and ethyl acetate to the mixture at a mass ratio of 2:3:4, stir and mix for 20 minutes to obtain the antirust active substance.

[0031] Curing agent: (1) Take epoxy resin E-44 and add castor oil polyglycidyl ether in a mass ratio of 1:1 to mix, stir and mix at 55°C for 20 minutes to obtain a stirred mixture, take the stirred mixture and add di Ethanolamine was stirred and mixed for 1 hour to obtain mixture a;

[0032] (2) Take ...

Embodiment 2

[0037] Anti-rust active substance: take dogwood seed husks and crush them through a 40-mesh sieve, collect the sieved particles, take the sieved particles and add distilled water at a mass ratio of 3:15, and then add 50% of the distilled water with a mass fraction of 25% hydroxymethylsulfonate Sodium acid solution, heat at 80°C for 5h, filter, take the filtrate to rotary evaporate, concentrate to 22 degrees Baume to get the concentrate, take the concentrate and mix it with polyvinyl butyral at a mass ratio of 5:9 to get the mixture, take Add acetone and ethyl acetate to the mixture at a mass ratio of 4:6:7, stir and mix for 30 minutes to obtain the antirust active substance.

[0038] Curing agent: (1) Take epoxy resin E-44 and mix it with castor oil polyglycidyl ether at a mass ratio of 4:3, stir and mix at 60°C for 30 minutes to obtain a stirred mixture, take the stirred mixture and add two Ethanolamine was stirred and mixed for 2 hours to obtain mixture a;

[0039] (2) Take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com