Graphene modified ceramic composite material, preparation method and product

A ceramic composite material and graphene modification technology, applied in the preparation method and its parts, in the field of graphene modified ceramic composite material, can solve problems such as inability to mix uniformly, composite material brittleness, fracture failure, etc., and achieve internal organization The effect of improved structure uniformity, fracture toughness and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

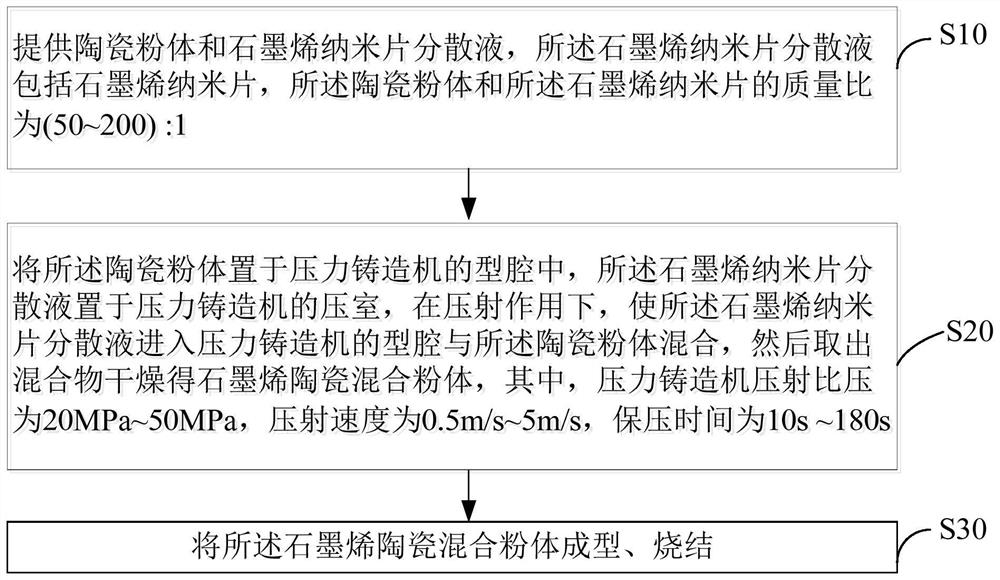

[0027] see figure 1 , the embodiment of the present invention provides a kind of preparation method of graphene modified ceramic composite material, comprises the following steps:

[0028] S10, ceramic powder and graphene nanosheet dispersion liquid are provided, and described graphene nanosheet dispersion liquid comprises graphene nanosheet, and the mass ratio of described ceramic powder body and described graphene nanosheet is (50~200): 1;

[0029] S20, placing the ceramic powder in the cavity of the die casting machine, placing the graphene nanosheet dispersion in the pressure chamber of the die casting machine, and making the graphene nanosheet dispersion Enter the cavity of the die casting machine and mix with the ceramic powder, and the mixture is dried to obtain a graphene ceramic mixed powder, wherein the injection specific pressure of the die casting machine is 20MPa~50MPa, and the injection speed is 0.5m / s~5m / s, the holding time is 10s~180s; and

[0030] S30, mol...

Embodiment 1

[0069] (1) Provide ceramic dispersion

[0070] Ceramic material: spherical silicon nitride with a particle size of 2 microns to 3 microns. First solvent: water. The first dispersant: polyethylene glycol.

[0071] Add 100g of spherical silicon nitride with a particle size of 2 to 3 microns and 2g of polyethylene glycol into 198g of water, stir and mix uniformly for 3 hours to obtain a spherical silicon nitride dispersion.

[0072] (2) Preparation of ceramic powder

[0073] The ceramic dispersion in step (1) is put into an oven for drying, and the temperature of the oven is set at 60° C. to obtain a spherical silicon nitride powder with a water content of less than 1%.

[0074] (3) Provide graphene nanosheet dispersion

[0075] Graphene nanosheets: the number of layers is 1 to 5 layers, and the sheet diameter is 1 micron to 5 microns. The graphene nanosheets are prepared by those skilled in the art through known processes.

[0076] Second solvent: N,N-dimethylformamide.

...

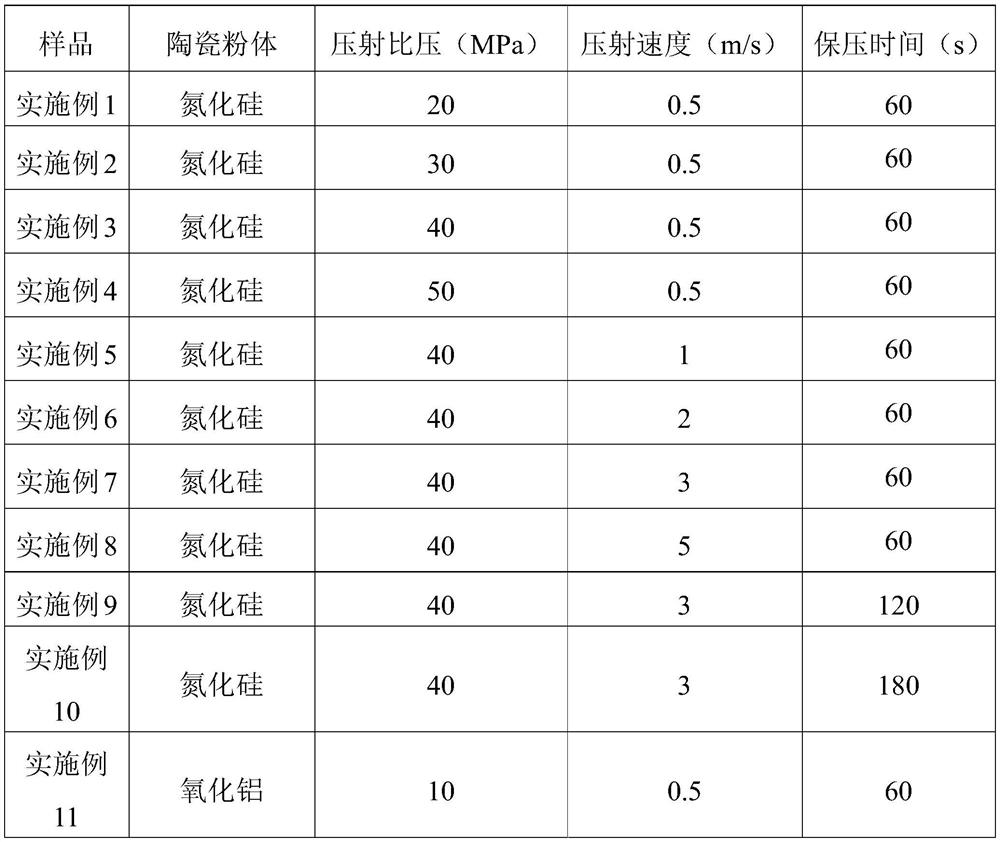

Embodiment 2

[0083] The preparation method obtained in Example 1 is basically the same, except that the specific injection pressure is 30 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com