Method for growing buffer layer of silicon carbide epitaxial material

A technology of epitaxial materials and growth methods, which is applied in the field of buffer layer growth of epitaxial materials, can solve problems such as low doping efficiency of buffer layers, unstable C/Si ratio, and increased defects, so as to improve doping efficiency and avoid C/Si Unstable Si ratio, mitigating effect of large doping difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

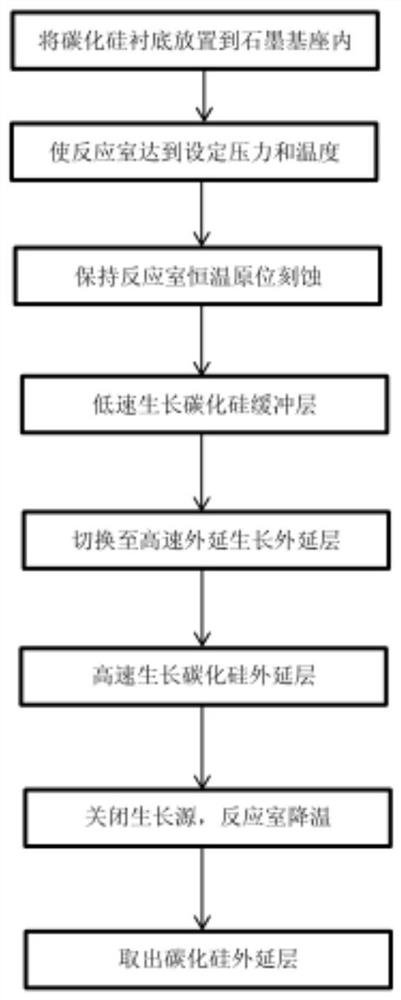

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

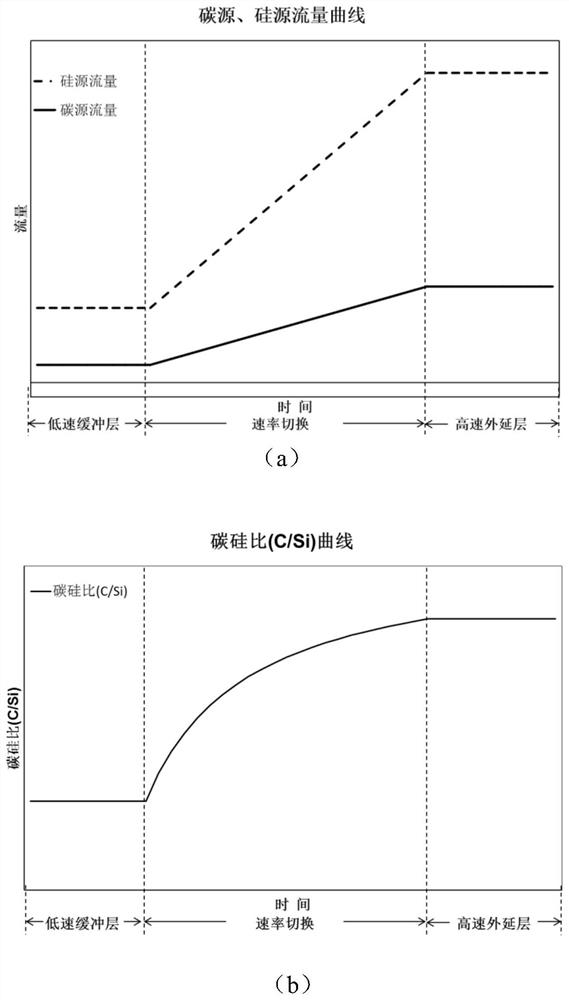

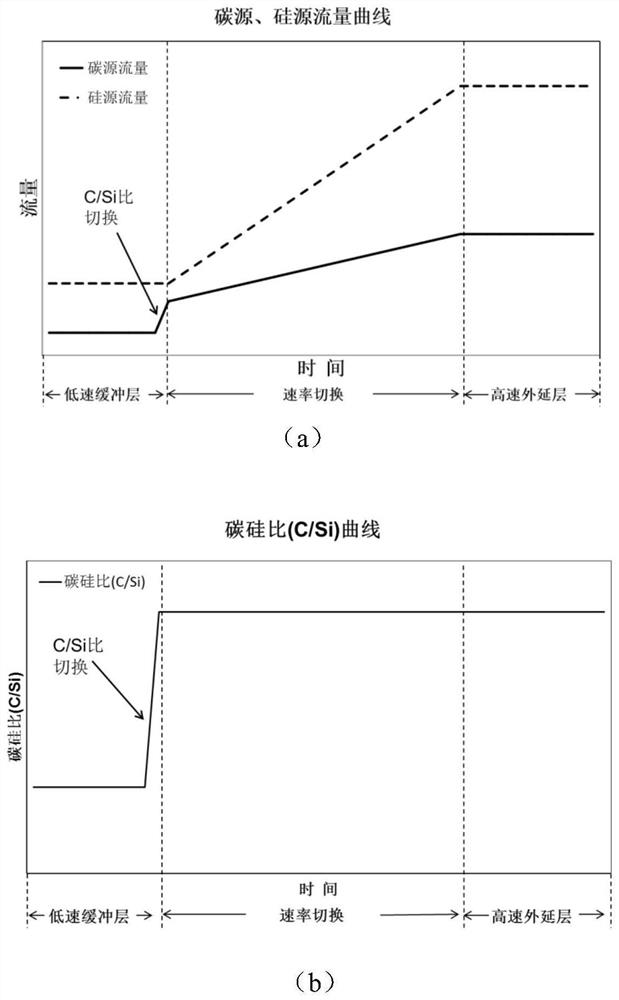

[0031] In order to reduce the influence of the substrate on the epitaxial layer, a buffer layer process is added to the epitaxial process. On the one hand, the buffer layer can reduce the stress and defects caused by the difference in doping concentration between the substrate and the epitaxial layer. On the other hand, it can also effectively It effectively suppresses the extension and amplification of substrate defects into the epitaxial layer, thereby effectively improving the quality of epitaxial materials and ensuring the performance of chips and devices. In order to ensure the effect of the buffer layer, the buffer layer of the present invention adopts a low-speed epitaxy process with a low carbon-to-silicon ratio (C / Si ratio) at the inlet end. figure 1 (a) Curves for the adjustment of carbon source and silicon source flow durin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com