Modular house capable of being quickly disassembled and assembled and production process

A modular and house-based technology, which is applied to building components, heat preservation, fire protection, etc., can solve the problems of many installation procedures and long construction periods, and achieve the effects of shortening installation time, saving construction time, and simple and efficient processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

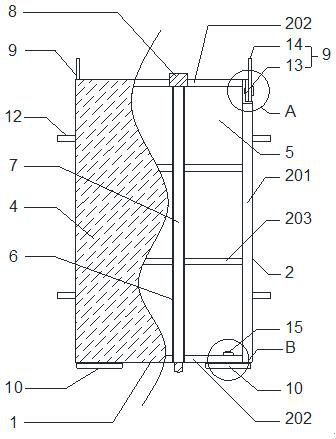

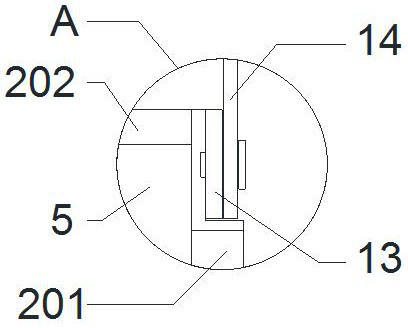

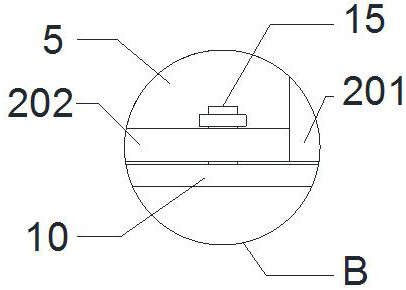

[0046] see Figure 1-8 , a modular house that can be quickly disassembled and assembled, including a house body composed of several assembled boards 1 spliced together; The side panels 101 constitute the walls on both sides, and the top panel 102 is arranged on the top of the side panels 101 to form a roof; the inside of the assembled panel 1 is provided with a skeleton 2, which provides overall support; the skeleton 2 is composed of arc-shaped steel pipes 201 and horizontal steel pipes 202, the two ends of the horizontal steel pipe 202 are respectively fixedly connected to the inner sides of the curved steel pipes 201 on both sides; One side of the skeleton 2 is provided with an inner skin 3, facing the indoor side, as an indoor wall surface, the inner skin 3 is custom-cut and made, and the gap after installation is very small, and there is no need to set other processing procedures inside; the other side of the skeleton 2 An outer skin 4 is provided, and the outer skin 4 ...

Embodiment 2

[0057] see Figure 9 , The difference between this embodiment and Embodiment 1 is that the assembly board 1 is a symmetrically arranged arc structure, and two assembly boards 1 are butted and installed to form a section of the house body, further reducing the assembly and installation process.

Embodiment 3

[0059] see Figure 10 , the difference between the present embodiment and the second embodiment is that the connection structure 9 is composed of two clamping plates, and a toughened glass plate 16 is installed on the top of the assembly plate 1 through the connection structure 9, and bright windows are set according to specific requirements, with good lighting effect.

[0060] In the present invention, the set frame 2 is composed of an arc-shaped steel pipe 201 and a horizontal steel pipe 202, and reinforcing ribs 203 are arranged inside to improve the overall stability; the arc-shaped steel pipe 201 is made by rounding and cutting a square steel pipe, and the overall processing steps are simple and efficient; Make different specifications according to the demand and actual size, quickly adapt to different needs, without complicated mold opening design steps; other connecting devices are welded, and the overall processing process is fast; the inner skin 3 is set as the indoor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com