Method for extracting L-homoserine from fermentation liquor

A technology of homoserine and fermentation liquid, which is applied in the direction of organic chemical methods, chemical instruments and methods, and the preparation of organic compounds, and can solve the problems of long treatment time, low product purity, and large acid-base consumption in electrodialysis technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

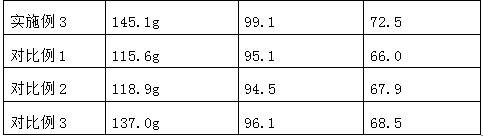

Examples

Embodiment 1

[0027] A method for extracting L-homoserine from fermentation broth, comprising the following steps:

[0028] Step 1. Fermentation broth pretreatment: Take 5L of fermentation broth from the upper tank, the concentration of homoserine is 35g / L, adjust the pH value of the fermentation broth to 4, add 20mg / L water-soluble chitosan flocculant, and heat to 60-80°C for treatment 20 minutes to promote the flocculation and precipitation of water-soluble miscellaneous proteins, the microfiltration membrane removes bacteria and flocs, and obtains 4.8L of fermentation broth clear liquid, using a roll-type ultrafiltration membrane separation system with a molecular weight cut-off of 0.5KDa and an operating pressure of 2.0MPa. Remove small molecular peptides and short-chain proteins in the fermentation liquid, and collect 4.7L of ultrafiltration membrane permeate;

[0029] Step 2. Decolorization: Pass the ultrafiltration membrane permeate collected in step 1 into a 5-inch activated carbon ...

Embodiment 2

[0040] A method for extracting L-homoserine from fermentation broth, comprising the following steps:

[0041]Step 1. Fermentation broth pretreatment: Take 5L fermentation broth from the upper tank, the concentration of homoserine is 35g / L, adjust the pH value of the fermentation broth to 5.8, add 80mg / L water-soluble chitosan flocculant, heat to 60-80°C for treatment For 40 minutes, promote the flocculation and precipitation of water-soluble miscellaneous proteins, microfiltration membranes remove bacteria and flocs, and obtain 5L of fermentation broth clear liquid, use roll-type ultrafiltration membrane separation system, the molecular weight cut-off is 10KDa, and the operating pressure is 4.0MPa. Remove small molecular peptides and short-chain proteins in the liquid serum, and collect 5L of ultrafiltration membrane permeate;

[0042] Step 2, decolorization: pass the ultrafiltration membrane permeate collected in step 1 into a 5-inch activated carbon fiber module device for d...

Embodiment 3

[0053] A method for extracting L-homoserine from fermentation broth, comprising the following steps:

[0054] Step 1. Fermentation broth pretreatment: Take 5L of fermentation broth from the upper tank, the concentration of homoserine is 40g / L, the pH of the fermentation broth is adjusted to 4.5, add 50mg / L water-soluble chitosan flocculant, and heat to 60-80°C for treatment For 30 minutes, the flocculation and precipitation of water-soluble miscellaneous proteins were promoted, and the bacteria and flocs were removed by the microfiltration membrane to obtain 4.9L of fermentation broth clear liquid. Using the roll-type ultrafiltration membrane separation system, the molecular weight cut-off was 5KDa, and the operating pressure was 3.0MPa. Remove small molecular peptides and short-chain proteins in the fermentation liquid, and collect 4.8L of ultrafiltration membrane permeate;

[0055] Step 2. Decolorization: Pass the ultrafiltration membrane permeate collected in step 1 into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com