Spectrum Selective Thermal Radiator and Its Design Method

A heat radiator and design method technology, applied in the field of heat radiation, can solve problems such as high temperature recession, achieve the effects of reducing manufacturing costs, overcoming cumbersome design and manufacturing, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

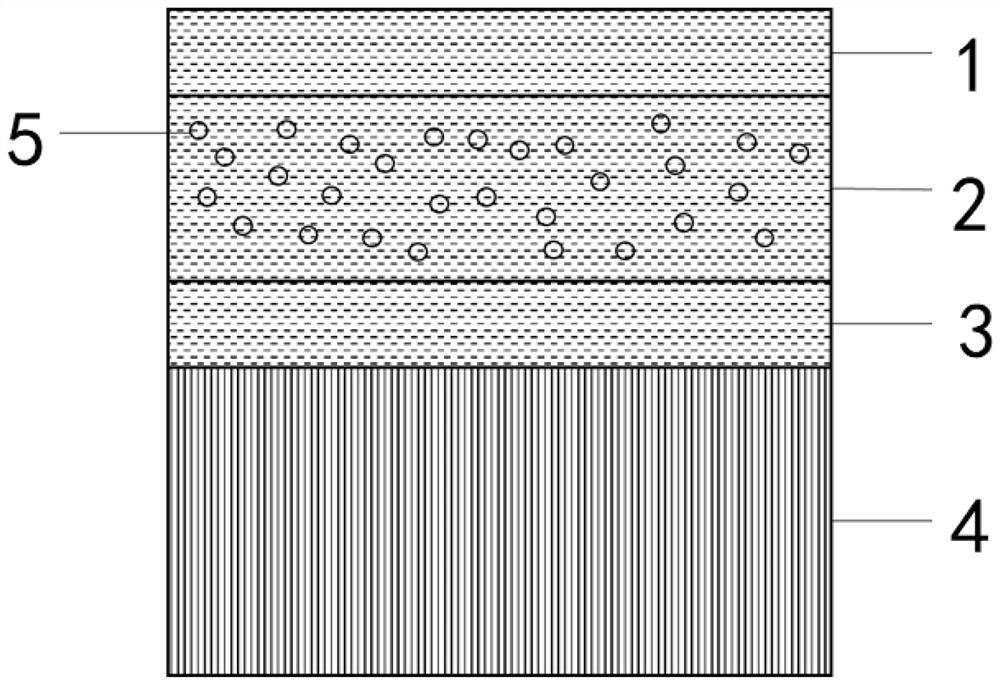

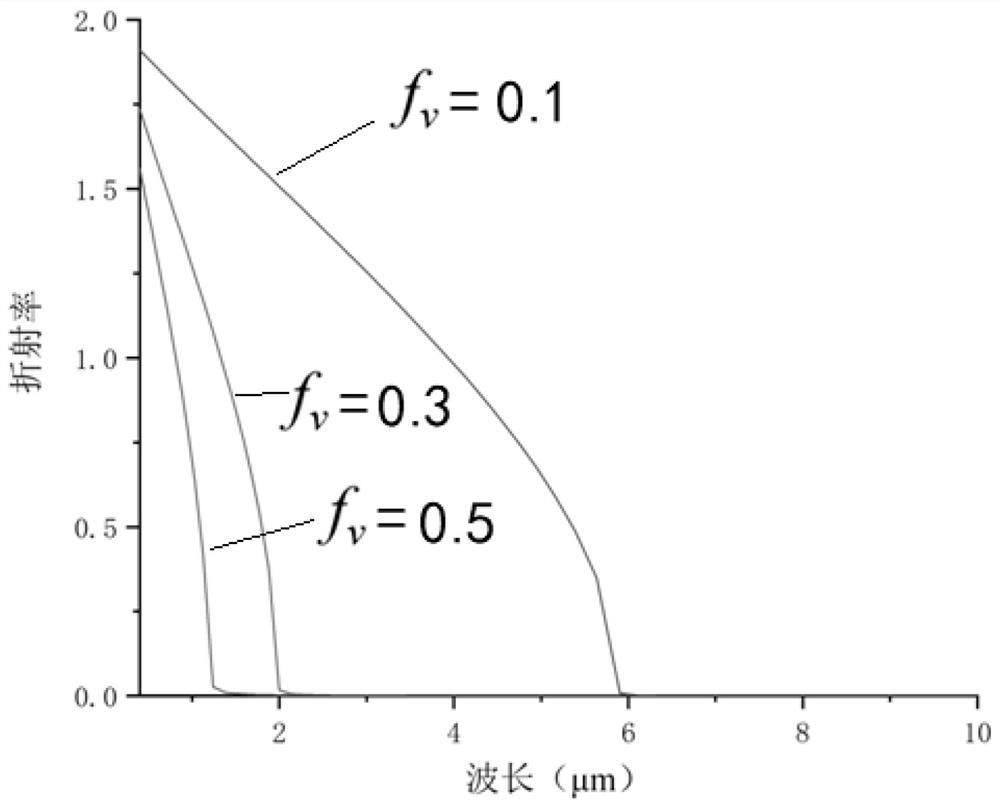

[0046] Such as figure 1 As shown, a material-type spectrally selective heat radiator is a one-dimensional layered structure, which is composed of a first layer 1, a second layer 2, a third layer 3 and a substrate 4 arranged in sequence from top to bottom, Wherein, both the first layer 1 and the third layer 3 are hafnium oxide layers, and the second layer 2 is a hafnium oxide layer distributed with a plurality of erbium oxide nanoparticles 5 . The thickness of the first layer 1 and the third layer 3 is 100 nm, and the thickness of the second layer 2 is 400 nm. The substrate 4 is a molybdenum substrate, and its size is 10mm×10mm×0.3mm. The particle size r=20nm of erbium oxide nanoparticles, its doping amount f in the second layer v = 0.1, 0.3 or 0.5.

[0047] The material-type hafnium oxide-doped erbium oxide particle spectrum selective heat radiator is prepared by radio frequency magnetron sputtering, using HfO with a purity of 99.99%. 2 and Er 2 o 3 Target material, the ...

Embodiment 2

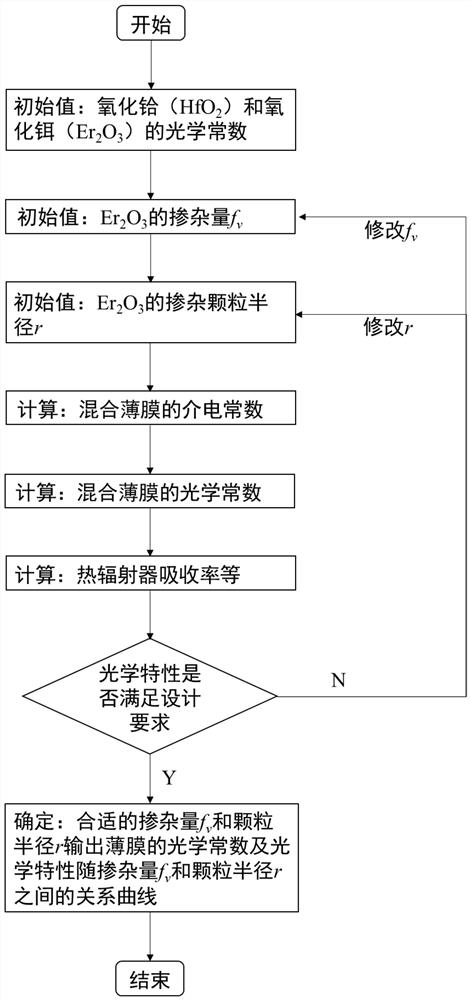

[0049] In the material-type spectrally selective thermal radiator, the optical constants of the functional layer doped with nanoparticles are usually difficult to determine, which is not conducive to the calculation of the overall optical properties of the subsequent thermal radiator. Therefore, using the effective medium theory and the transfer matrix method to calculate the optical characteristics of the spectrally selective thermal radiator doped with nanoparticles as a function of the doping amount and particle size of the nanoparticles in the functional layer, can effectively reflect the overall optical properties of the radiator. Changes in characteristics, and predict the future performance of the heat radiator.

[0050] Based on this, the present invention discloses a design method of the material-type spectrally selective thermal radiator in Embodiment 1, such as figure 2 shown, including the following steps:

[0051] 1) Determine hafnium oxide (HfO 2 ) of the refr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com