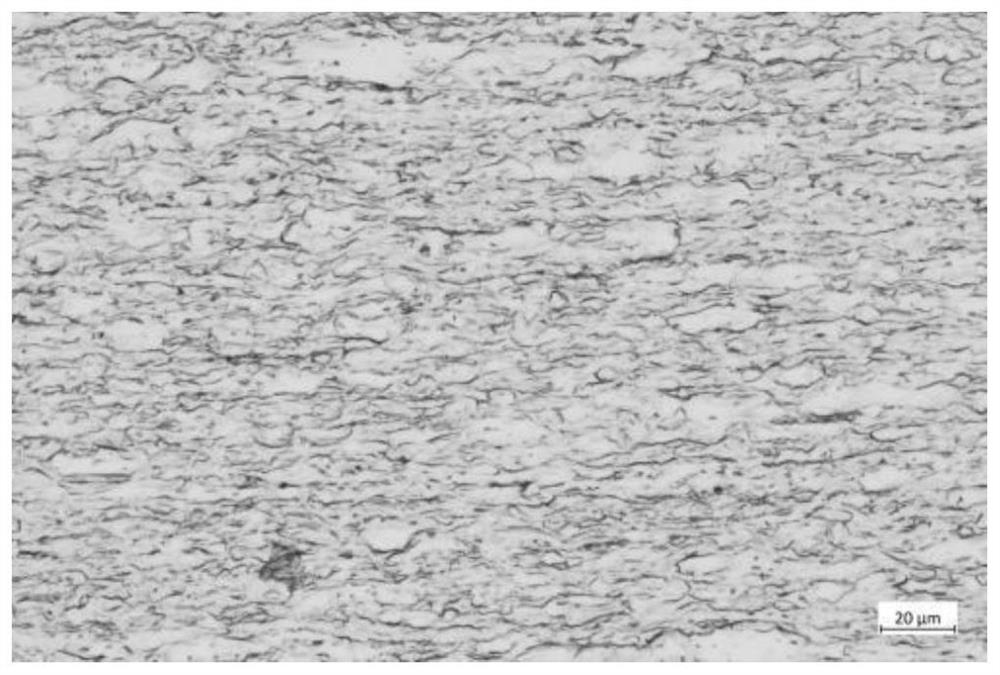

Corrosion method for clearly displaying metallographic structure of cold-rolled alpha+beta type titanium alloy pipe

A technology for clearly displaying the metallographic structure, which is applied in the corrosion field of clearly displaying the metallographic structure of the cold-rolled α+β-type titanium alloy pipe, which can solve the problems of unfavorable accurate characterization and inconspicuous metallographic structure, and improve the corrosion effect , improve efficiency, broad application value and prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take a polytetrafluoroethylene beaker with a capacity of 300mL, add 100mL of deionized water, measure 1mL of hydrofluoric acid and add it, weigh 2g of ammonium bifluoride powder and add it into the solution, stir until it is completely dissolved, and let it stand for 2 minutes to obtain solution A; add 8mL of concentrated nitric acid and 2mL of concentrated sulfuric acid. During this process, it is necessary to pay attention to the continuous stirring when adding concentrated sulfuric acid to avoid safety accidents. Weigh 3g of oxalic acid powder and add it to the solution, and then add 10mL of methanol to obtain solution B; Place in the ice-water mixture, control the temperature of solution B at 0-4°C, soak the ground and polished metallographic sample in the solution, wipe the surface of the sample to be inspected at a frequency of 3 times / min, and the corrosion time for 2 minutes, then take it out, rinse with water, and blow dry.

Embodiment 2

[0034] Take a polytetrafluoroethylene beaker with a capacity of 300mL, add 100mL of deionized water, measure 0.5mL of hydrofluoric acid into it, weigh 2g of ammonium bifluoride powder into the solution, stir until completely dissolved, and let it stand for 2 minutes to obtain solution A; Add 5mL of concentrated nitric acid and 1mL of concentrated sulfuric acid. During this process, it is necessary to keep stirring when adding concentrated sulfuric acid to avoid safety accidents. Weigh 3g of oxalic acid powder and add it to the solution, and then add 10mL of methanol to obtain solution B; Place B in a mixture of ice and water, control the temperature of solution B at 0-4°C, soak the ground and polished metallographic sample in the solution, wipe the surface of the sample to be inspected at a frequency of 4 times / min, and corrode The time is 3 minutes, then take it out, rinse with clean water, and blow dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com