Transformer oil level measuring device

A measuring device and transformer oil technology, applied in the direction of measuring device, lubrication indicator device, liquid/fluid solid measurement, etc., can solve the problems of inaccurate measurement, affecting measurement accuracy, error, etc., to save construction time, improve safety, The effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

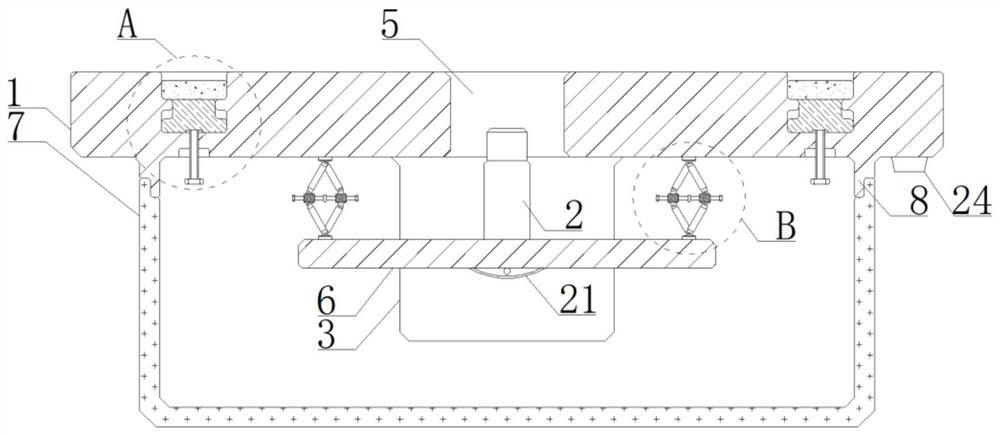

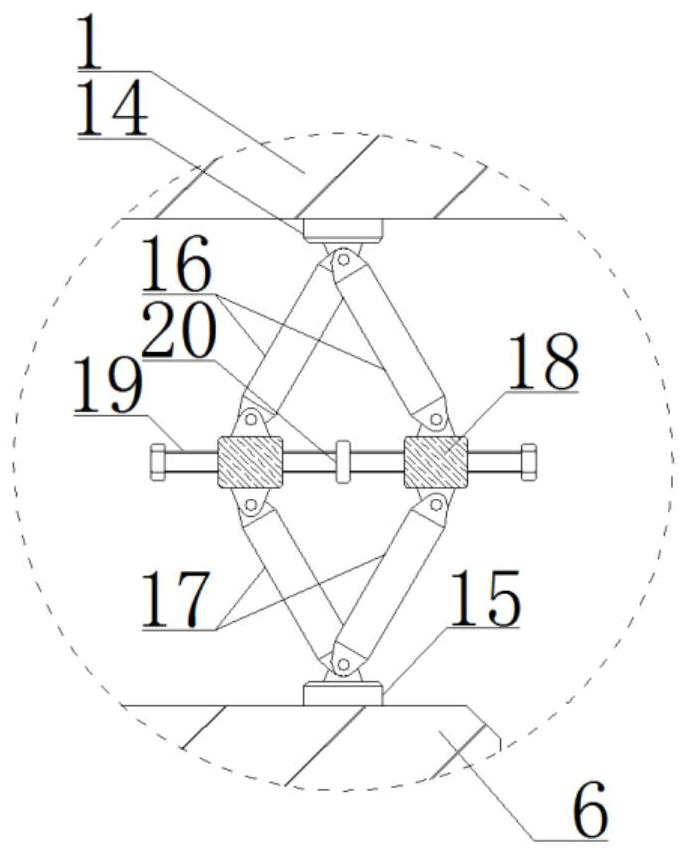

[0026] see Figure 1-4 , a transformer oil level measuring device, which is installed with the transformer oil tank and detects the oil level in the oil tank, including an installation base 1, a leveling mechanism, an ultrasonic probe 2, an electronic display screen 3, and a control unit 4;

[0027] The installation base 1 is fixedly installed on the bottom of the transformer oil tank. The ultrasonic probe 2 is installed together with the leveling mechanism on the installation base 1. The leveling mechanism adjusts the installation angle of the ultrasonic probe 2. The oil level in the tank is detected, and the installation base 1 is also equipped with an electronic display screen 3 and a control unit 4. The ultrasonic probe 2 is connected to the control unit 4 for signals. The control unit 4 is used to record the ultrasonic signal transmitted by the ultrasonic probe 2 to the transformer oil tank. Time and the time when the ultrasonic signal is reflected to the ultrasonic probe...

Embodiment 2

[0030] see Figure 1-4 Embodiment 1 is further described and supplemented in detail. In the present invention, a protective cover 7 is also provided, and an installation ring 8 is fixed on the edge of the installation base 1, and the protective cover 7 is screwed on the installation ring 8 and will be leveled. Mechanism, ultrasonic probe 2, electronic display 3, and control unit 4 are wrapped in it to protect the leveling mechanism, ultrasonic probe 2, electronic display 3, and control unit 4; the protective cover 7 is made of transparent engineering plastics to ensure that the protective cover 7 While improving the overall hardness, the oil level displayed on the electronic display screen 3 can be observed.

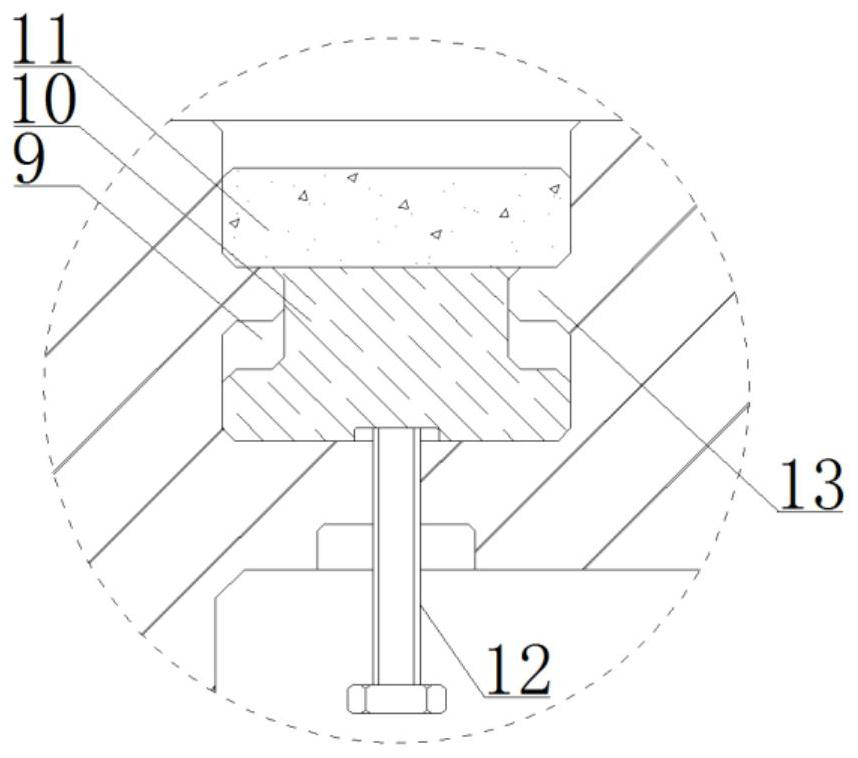

[0031] The edge position of the upper surface of the installation base 1 is provided with multiple sets of installation grooves 9, and a sliding installation seat 10 is nested and installed in the installation groove 9 in a relatively sliding manner, and a powerful magne...

Embodiment 3

[0038] see Figure 1-4 , to explain the working principle of the present invention: when installing the present invention on the bottom of the transformer oil tank, first place the upper surface of the installation base 1 close to the transformer oil tank, and control the corresponding sliding mounting seat 10 and the strong force by twisting each group of driving screws 12 The magnet 11 moves upwards and is stably adsorbed on the bottom of the iron transformer oil tank; then, by rotating each group of driving screws 12 and continuously observing the indication status of the level meter 21, it is ensured that the installation substrate 6 is adjusted to a horizontal state, thereby ensuring that the ultrasonic probe 2 is vertically oriented The oil level in the transformer oil tank improves the accuracy of the ultrasonic probe 2 in detecting the oil level; finally, the protective cover 7 is installed on the mounting ring 8 to protect the leveling mechanism, the ultrasonic probe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com