Carbon fiber resin-based composite material and preparation method thereof

A technology of carbon fiber resin-based and composite materials, which is applied in the field of carbon fiber resin-based composite materials and can solve problems such as failure of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

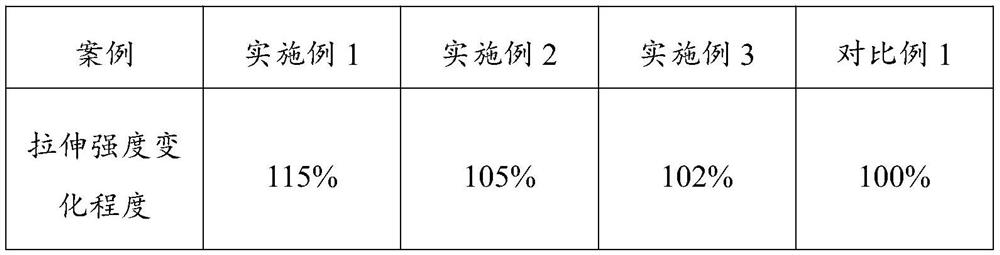

Examples

preparation example Construction

[0022] The invention provides a method for preparing a carbon fiber resin-based composite material, comprising the following steps:

[0023] Mix carbon fibers and acid reagents, and perform surface oxidation treatment to obtain oxidized carbon fibers;

[0024] Mixing the oxidized carbon fibers with thionyl chloride, and performing surface acyl chloride treatment to obtain carbon acid chloride fibers;

[0025] In subcritical water, the acyl chloride carbon fiber, melamine solution and condensation agent are mixed for grafting to obtain modified carbon fiber;

[0026] mixing epoxy-containing resin matrix, carboxyl-terminated nitrile rubber, curing agent and coupling agent, and modifying to obtain modified resin;

[0027] The carbon fiber bundle formed by the modified carbon fiber is soaked in the melted modified resin, and after curing, a carbon fiber resin-based composite material is obtained.

[0028] In the present invention, unless otherwise specified, the required prepara...

Embodiment 1

[0055] Clean the carbon fibers, then place them in concentrated nitric acid (68% mass concentration), and carry out surface oxidation treatment at 95° C. for 1 hour to obtain oxidized carbon fibers;

[0056] Mix the oxidized carbon fibers with thionyl chloride (the mass ratio of oxidized carbon fibers to thionyl chloride is 1:20), perform surface acid chlorination treatment at 70°C for 22 hours, wash the resulting product with alcohol, filter and dry in sequence to obtain acid chloride carbon fiber;

[0057] In subcritical water, the carbonyl chloride fiber and melamine solution (3g / L) and 20mg dicyclohexylcarbodiimide (the mass ratio of carbonyl chloride fiber, melamine solution and condensing agent are 1:5:0.1) are loaded into In the reaction kettle, put the reaction kettle in an oven and heat it to 350°C for 15 minutes to carry out grafting. After the reaction is over, after the reaction kettle is cooled to room temperature, take out the fiber product, wash it with deionize...

Embodiment 2

[0061] Clean the carbon fibers, then place them in concentrated nitric acid (68% mass concentration), and perform surface oxidation treatment at 85° C. for 1 hour to obtain oxidized carbon fibers;

[0062] Mix the carbon oxide fiber with thionyl chloride (the mass ratio of carbon oxide fiber to thionyl chloride is 1:20), carry out surface acid chlorination treatment at 70°C for 24 hours, wash the obtained product with alcohol in sequence, filter and dry to obtain the acid chloride carbon fiber;

[0063] In subcritical water, the carbonyl chloride fiber and melamine solution (3g / L) and 20mg dicyclohexylcarbodiimide (the mass ratio of carbonyl chloride fiber, melamine solution and condensing agent are 1:5:0.1) are loaded into In the reaction kettle, put the reaction kettle in an oven and heat it to 350°C for 15 minutes to carry out grafting. After the reaction is over, after the reaction kettle is cooled to room temperature, take out the fiber product, wash it with deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com