Tunnel advance horizontal jet grouting pile built-in steel pipe positioning device

A technology of horizontal rotary jetting pile and positioning device, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as position deviation, and achieve the effects of fast efficiency, simple installation and improved pile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

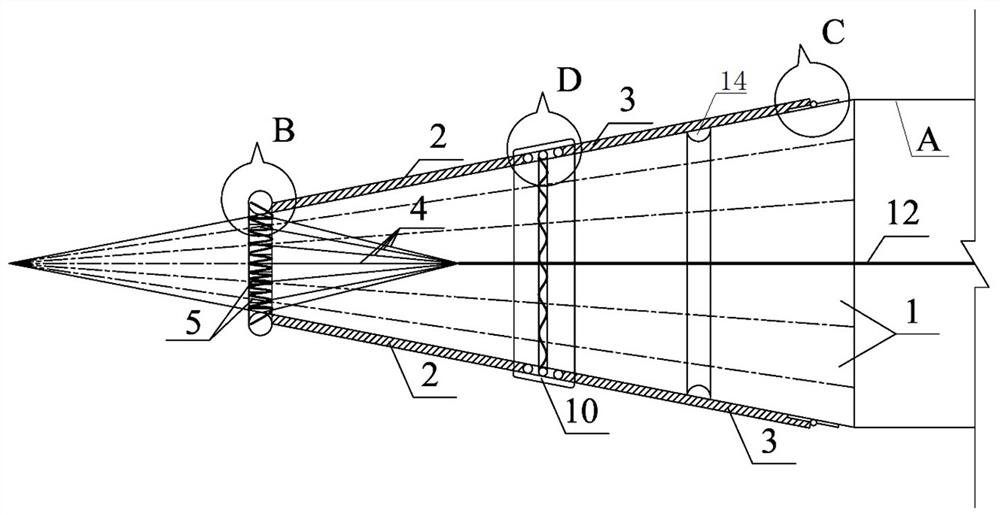

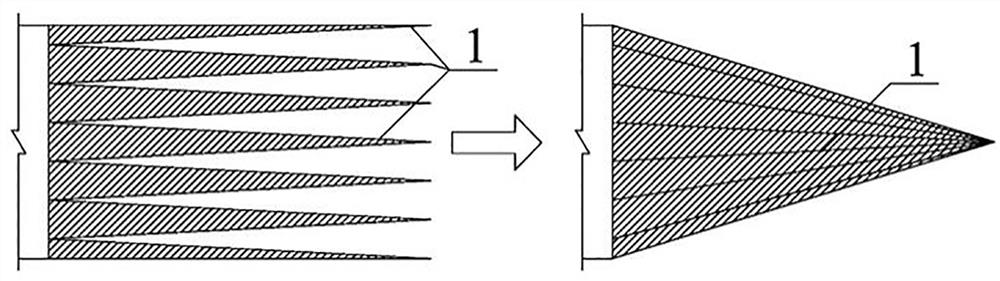

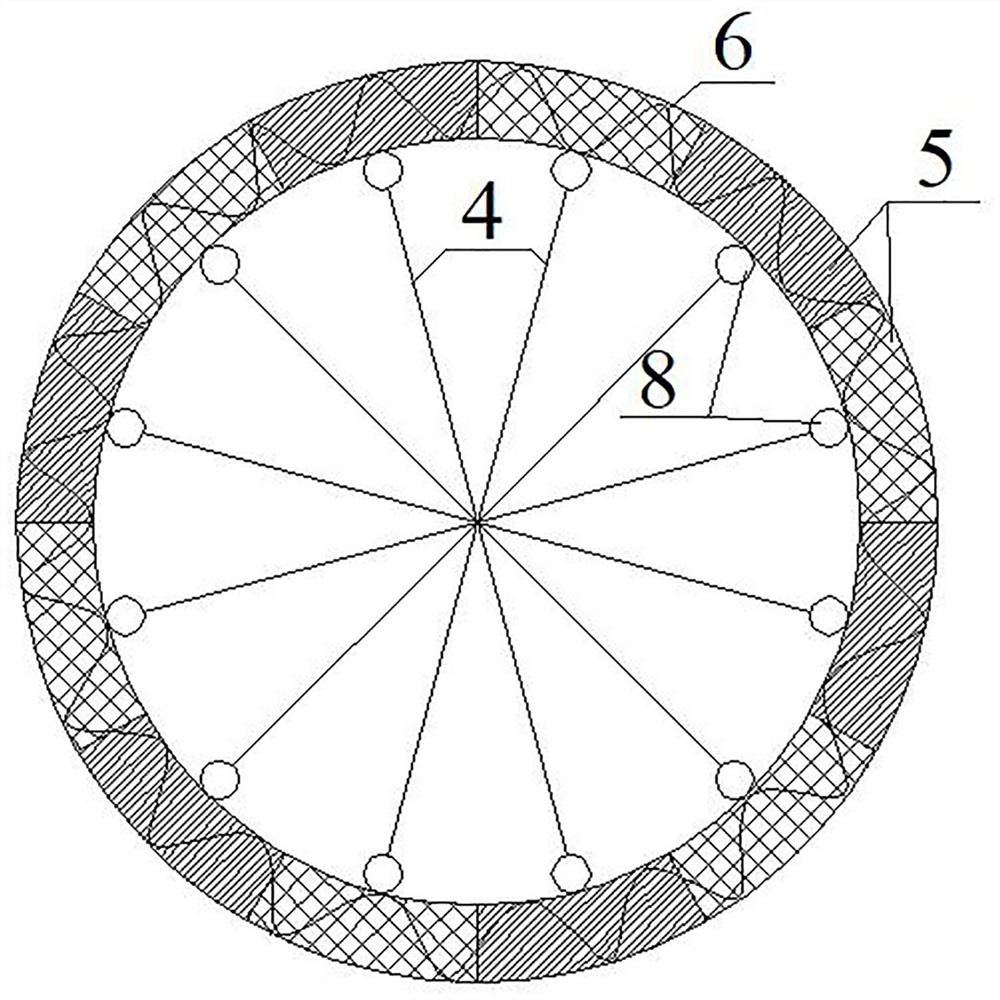

[0035] like Figure 1-11 As shown in the figure, a built-in steel pipe positioning device for an advanced horizontal rotary jetting pile in a tunnel includes a plurality of front support rods 2 arranged at intervals in a small section of the cone portion of the steel pipe and a plurality of rear support rods arranged at intervals in a large section of the cone section of the steel pipe. 3. A support body D is arranged between the front support rod 2 and the rear support rod, and the support body D includes a support plate 10, and hinges 9 are welded on both sides of the bottom of each support plate 10. The support rod 2 is welded, one end of the other hinge 9 is welded with the rear support rod 3, the bottom of each support plate 10 is welded with a sleeve 7, the sleeve 7 is connected by a soft spring 11, and the two ends of the soft spring 11 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com