Hopper device and construction method for laying of tunnel inverted arch cushion layer

A technology for tunnels and hoppers, which is applied in the field of hopper devices for laying inverted arch cushions in tunnels. It can solve the problems of poor control of height direction accuracy, reduced construction speed and efficiency, and difficult control of initial support quality, so as to improve construction speed and The effect of improving efficiency, improving automation rate and improving laying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

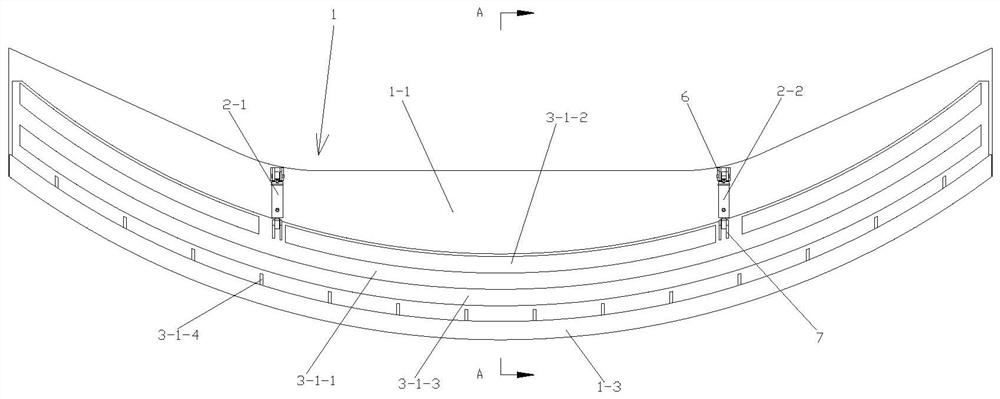

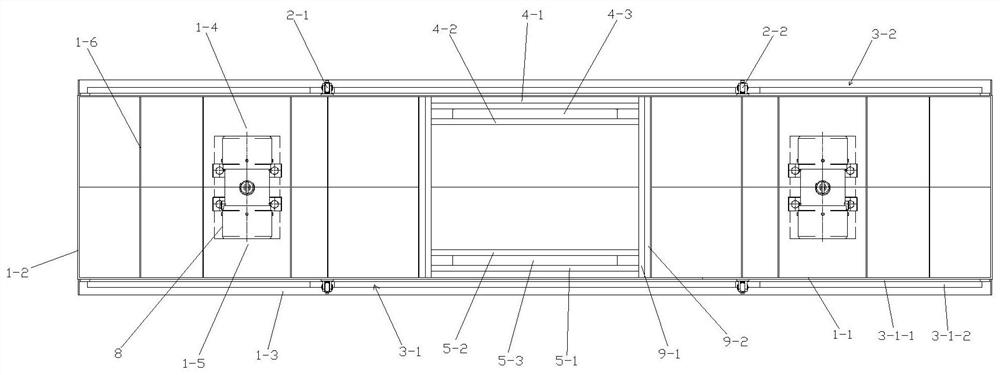

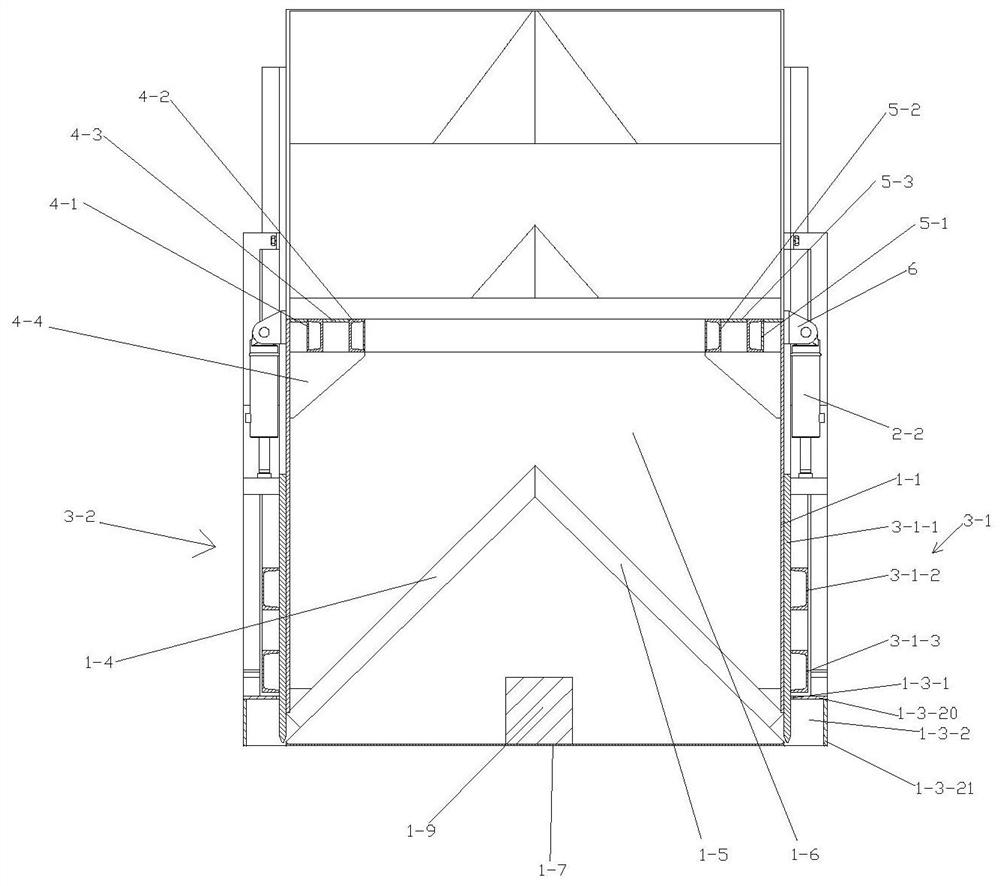

[0058] Such as Figure 1 to Figure 3 The shown hopper device for laying the invert cushion of a tunnel includes a hopper body 1, a gate mechanism arranged on the hopper body 1 and a vibration mechanism arranged on the hopper body 1, and the hopper body 1 The bottom is an inferior arc, and the bending direction of the bottom of the hopper body 1 is consistent with the bending direction of the excavation surface of the inverted arch of the tunnel. The two sides of the hopper body 1 are provided with a plurality of discharge ports 1-3-2, and a plurality of The discharge port 1-3-2 is arranged along the arc length direction of the hopper body 1, the gate mechanism controls the opening or closing of the discharge port 1-3-2, and the top opening of the hopper body 1 . The vibrating mechanism can not only drive the bean gravel in the hopper body 1 to vibrate, but also vibrate the bean gravel on the excavation surface of the inverted arch of the tunnel.

[0059] In this embodiment, ...

Embodiment 2

[0069] In this embodiment, the hopper body 1 includes two symmetrically arranged side plates 1-1, end plates 1-2 symmetrically installed at both ends of the two side plates 1-1 and connected to the bottom of the two side plates 1-1. bottom plate 1-7, the bottom plate 1-7 is a inferior arc, the bending direction of the bottom plate 1-7 is consistent with the bending direction of the tunnel inverted arch excavation surface, and the bottom of the outer wall of the side plate 1-1 is provided with The discharge table 1-3, a gap for the gate mechanism to pass through is provided between the discharge table 1-3 and the outer side wall of the side plate 1-1.

[0070] Further preferably, a plurality of clamping blocks 1-3-1 are arranged between the discharge platform 1-3 and the outer wall of the side plate 1-1, and an outlet is formed between two adjacent clamping blocks 1-3-1. The material outlet 1-3-2, and a plurality of the material outlets 1-3-2 are arranged in an arc shape.

[0...

Embodiment 3

[0079] In this embodiment, the hopper body 1 is provided with a first inclined plate 1-4 and a second inclined plate 1-5, and the first inclined plate 1-4 and the second inclined plate 1-5 are arranged along the bottom plate 1- 7 Arranged in the arc length direction, the connecting line at the top of the first inclined plate 1-4 and the second inclined plate 1-5 is arc-shaped, and the two sides of the first inclined plate 1-4 and the second inclined plate 1-5 The end fits with the end plate 1-2.

[0080] Further preferably, the first inclined plate 1-4 and the second inclined plate 1-5 are provided with a plurality of partitions 1-6, and the plurality of partitions 1-6 are arranged along the first inclined plate 1-4 and the second inclined plate. The two inclined plates are arranged in the arc length direction of 1-5.

[0081] Further preferably, the angle formed between the first inclined plate 1-4 and the second inclined plate 1-5 is less than 90°.

[0082] Further prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com