Silver-plated graphene/synthetic rubber latex composition, and preparation and application thereof

A technology of synthetic rubber and graphene, which is applied in the field of rubber, can solve the problems of endangering the health of operators, poor dispersion of fillers, and flying powder, etc., and achieves the effects of industrial scale-up, excellent antibacterial performance, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

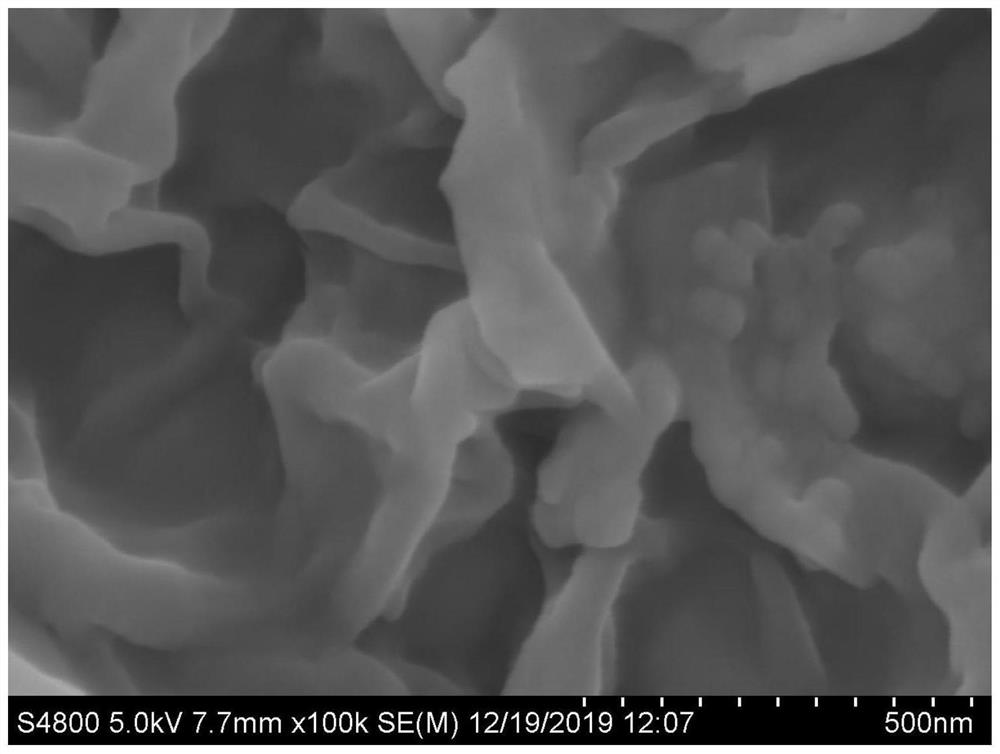

[0048] (1) silver on the graphene

[0049] Graphene oxide weighed 1.5g, dissolved in the water to give sonication 100mL deionized graphene dispersion; 0.3g of dopamine was dissolved in 100mL Tris-HCl buffer (10mM, PH = 8.5) was prepared in dopamine; formulated good graphene dopamine was added to the above solution, and mixing uniformly; Weigh 0.5g of silver nitrate was dissolved in 100g of water, aqueous ammonia was added dropwise until the solution clarified just added 0.25gPVP, mixing uniformly, added to the mixed solution, mixing and stirring, 100mL added at a concentration of 10g / L glucose solution, stirred for 1 hour;

[0050] (2) Preparation of graphene silver / synthetic rubber latex composition

[0051] Take 180g polyurethane latex, the step (1) was added to the resulting latex ultrasonic agitation 20min, to obtain graphene the silver / synthetic rubber latex composition;

[0052] (3) Preparation of graphene silver / synthetic rubber latex film article composition

[005...

Embodiment 2

[0055] (1) silver on the graphene

[0056] Graphene weighed 0.1g, dissolved in water after sonication graphene dispersion 60mL deionized; dissolving 0.4g of dopamine dopamine solution was prepared in 100mL Tris-HCl buffer solution (10mM, PH = 8.5); and the prepared graphene dopamine was added to the above solution, and mixing uniformly; Weigh 1g silver nitrate was dissolved in 100g of water, aqueous ammonia was added dropwise until the solution clarified just added 0.25gPVP, uniformly mixed with stirring, was added the above mixture was mixed and stirred was added 50mL concentration of 1g / L glucose solution, stirred for 1 hour;

[0057] (2) Preparation of graphene silver / synthetic rubber latex composition

[0058] Take 180g of silicone rubber latex, in the step (1) was added to the resulting latex ultrasonic agitation 20min, to obtain graphene the silver / synthetic rubber latex composition;

[0059] (3) Preparation of graphene silver / synthetic rubber latex film article comp...

Embodiment 3

[0062] (1) silver on the graphene

[0063] After the graphene weighed 0.8g, was dissolved in 70mL of deionized water, sonicated to obtain a graphene oxide dispersion; 0.5g of tannic acid was dissolved tannic acid solutions were prepared in buffer solution 100mL Tris-HCl (10mM, PH = 8.5) in the ; graphene the prepared solution was added to the above solution of tannic acid, homogeneously mixing; 1g silver fluoride was dissolved in an aqueous solution 100mL added dropwise 0.5g / L ammonium chloride solution until the solution is just to clarify, 0.25 gPVP, mixing evenly, was added the above mixture was mixed and stirred, was added 50mL concentration of 1g / L glucose solution, stirred for 1 hour;

[0064] (2) Preparation of graphene silver / synthetic rubber latex composition

[0065] Take 180g styrene-butadiene latex, in step (1) was added to the resulting latex ultrasonic agitation 20min, to obtain graphene the silver / synthetic rubber latex composition;

[0066] (3) Preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com