Carbon-coated silicon negative electrode material with hollow structure and preparation method thereof

A negative electrode material, carbon coating technology, applied in the field of electrochemical energy storage, can solve problems such as silicon powder pulverization, and achieve the effect of solving silicon powder pulverization and inhibiting excessive volume expansion of silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Ultrasonically disperse 0.06g of silicon powder in 50mL of methanol, under stirring conditions, add 1.72g of 2-methylimidazole respectively according to the molar ratio of silicon powder, 2-methylimidazole and cobalt nitrate as 1:6:2 and 1.28 g of cobalt nitrate.

[0027] (2) After standing for 2 hours, centrifuge and freeze-dry for 12 hours to obtain the precursor Si@ZIF-67.

[0028] (3) According to the mass ratio of tannic acid to Si@ZIF-67 of 2:5, 0.62 g of tannic acid was added to a 300 mL solution with a volume ratio of ethanol and water of 1:1 and stirred for 10 minutes to obtain a tannic acid solution.

[0029] (4) Ultrasonic disperse the Si@ZIF-67 in step (2) in 30mL ethanol, add the tannic acid solution in step (3) under stirring condition, let stand for 2 hours, centrifuge and wash with ethanol 3 times , freeze-dried for 2 hours.

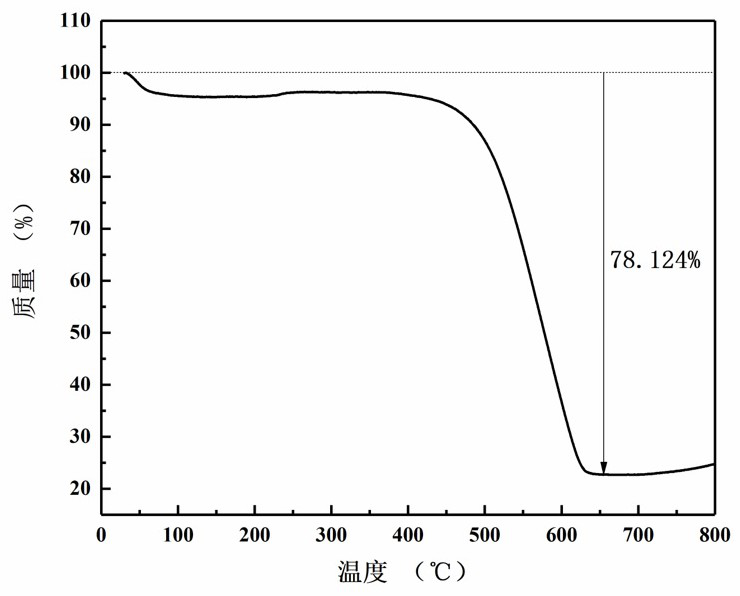

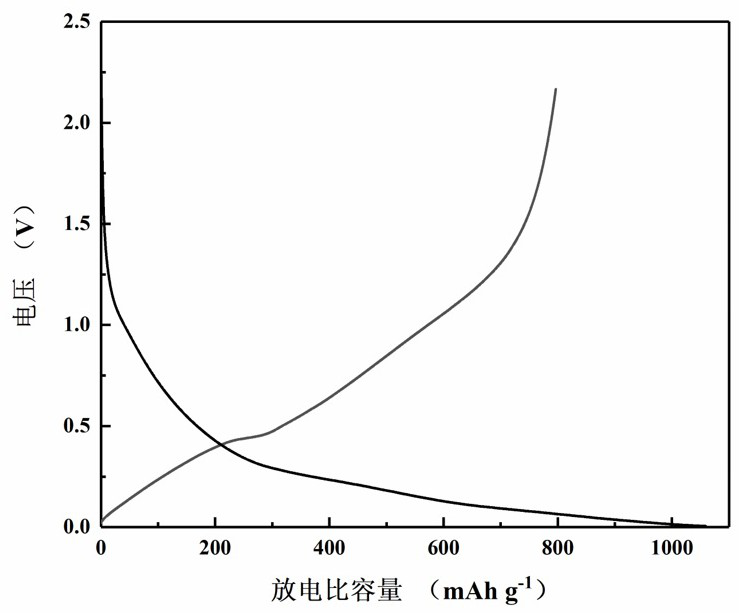

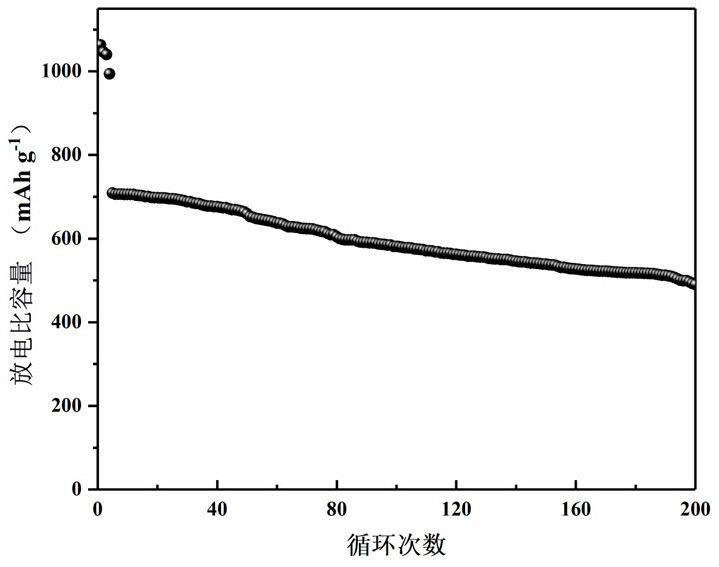

[0030] (5) The dried product obtained in step (4) was heated up to 800°C for carbonization at a rate of 5°C / min and held fo...

Embodiment 2

[0032] A method for preparing a carbon-coated silicon negative electrode material with a hollow structure is basically the same as that of Example 1, the difference being:

[0033] In step (1), cobalt chloride is used to replace cobalt nitrate, and the dosage is 0.90 g.

Embodiment 3

[0035] A method for preparing a carbon-coated silicon negative electrode material with a hollow structure is basically the same as that of Example 1, the difference being:

[0036] The drying method adopted is ordinary drying at 80° C. for 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com