Intelligent coarse particles for vibration reduction and power generation

A coarse-grained and intelligent technology, applied in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problem of low energy consumption, small dynamic strain, and speed up ballast crushing speed and other issues to achieve the effect of reducing vibration energy, prolonging service life, and improving vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

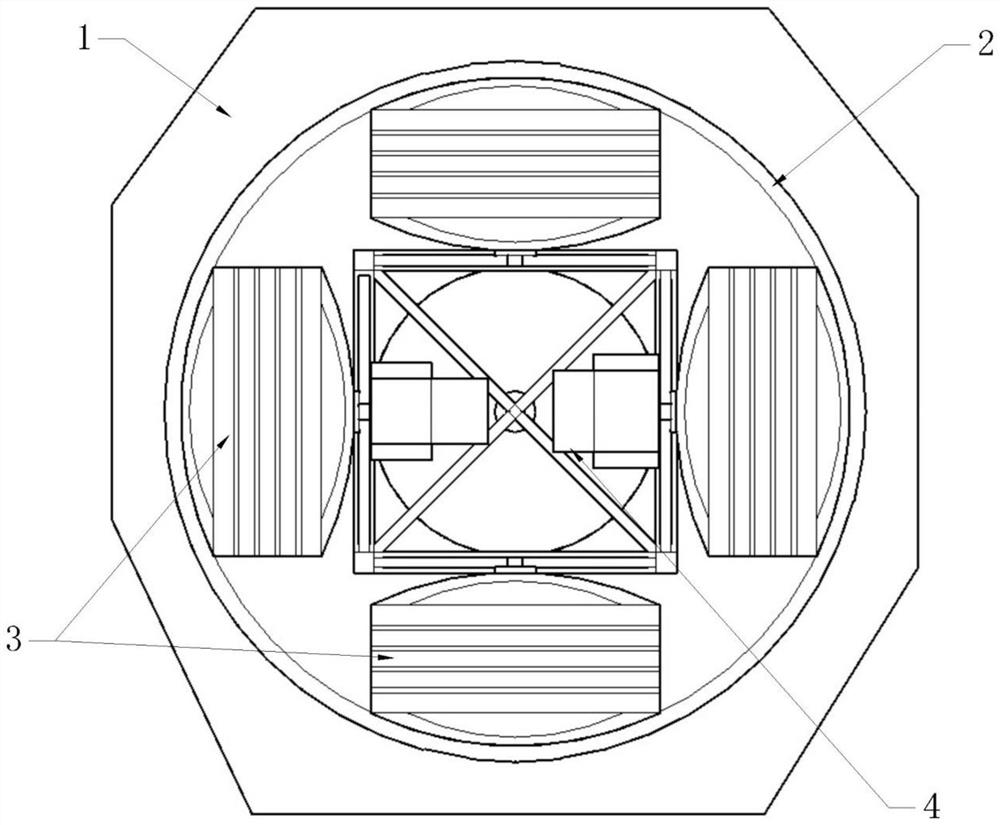

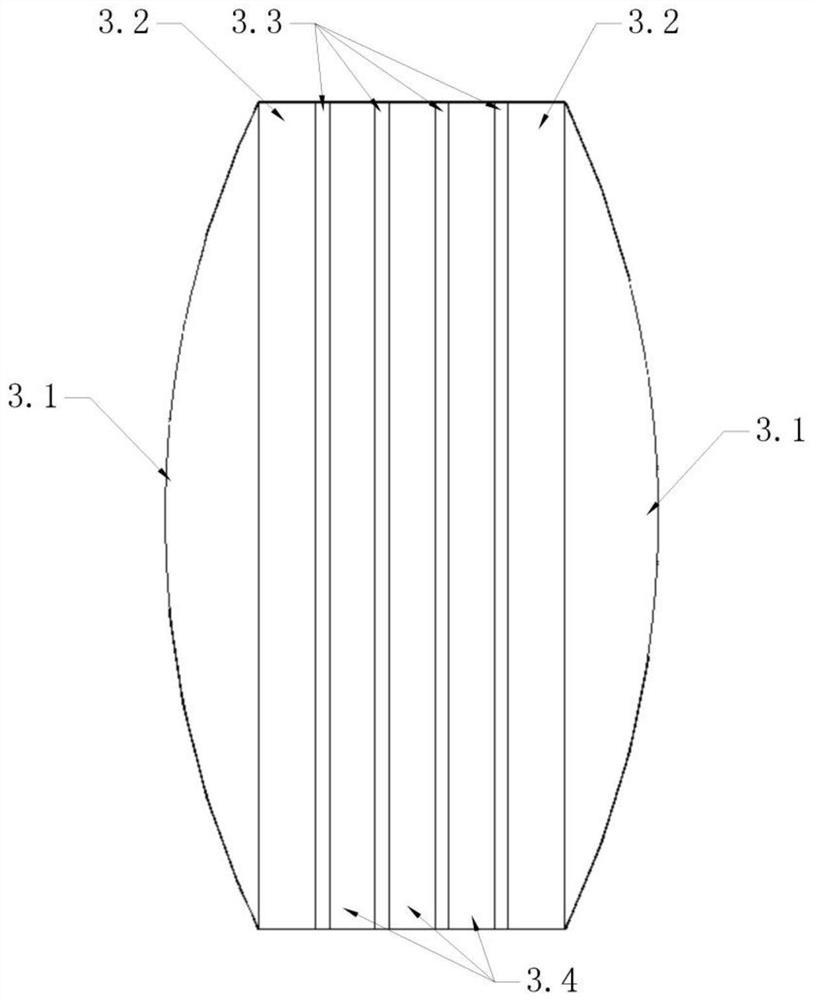

[0024] Embodiment one: if figure 1 As shown, a kind of smart coarse particles for vibration reduction and power generation, such as ballast in ballasted railways. Coarse particles include a concrete shell 1, a steel shell 2, several piezoelectric vibration-absorbing energy harvesters 3, and an electric energy collection and conversion structure 4 from the outside to the inside. The conversion structure 4 is used to convert the stress of the concrete shell 1 and the steel shell 2 into electricity, and the electric energy collection and conversion structure 4 converts the electricity into stable electric energy and stores it.

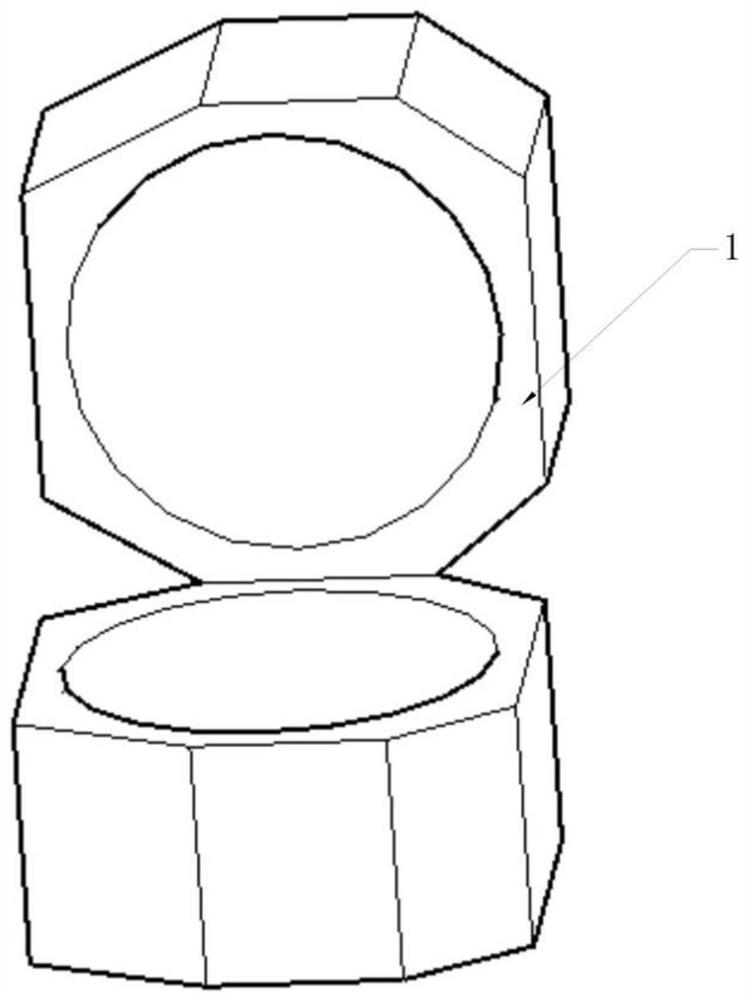

[0025] combine figure 2 As shown, the concrete shell 1 is manufactured and assembled by 3D printing technology. The outer contour is selected according to the usage scenario. If it is used as ballast, the printed size is close to the size of ordinary ballast. The strength and rigidity meet the requirements of ordinary ballast. The interior has a smooth ...

Embodiment 2

[0030] Embodiment 2: The difference from Embodiment 1 is that the shape of the steel shell 2 and the high-rigidity steel frame 4.1, and the number of piezoelectric vibration-absorbing energy harvesters 3 can be adjusted accordingly according to different usage scenarios.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com