Standard sample for verifying vibration testing capacity

A proficiency testing, standard sample technology, applied in vibration testing, machine/structural component testing, measuring devices, etc., to solve problems such as high dynamic stress, difficulty in testing the vibration characteristics of vertical and horizontal slide tables, and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing.

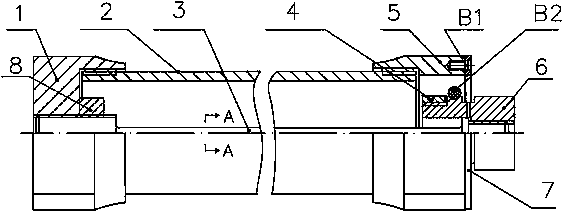

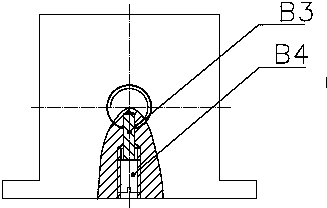

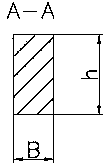

[0017] The present invention as figure 1 As shown, the section at A-A is shown as image 3 As shown, it includes the left support 1 and the right support 5 connected by the connecting cylinder 2, the bottom of the two supports is provided with lugs, the right end opening of the right support 5 is sealed by the cover plate 7, and the right end opening of the right support 5 is connected with the cover plate 7 is connected by the second screw B1. There is a resonant beam 3 with a rectangular section in the center of the connecting cylinder 2. The resonant beam 3 is a single rectangular beam. The ratio of the section height h to the width B can be selected according to actual needs, for example, the aspect ratio can be selected as 2:1. The left end of the resonant beam 3 is connected to the left support, and the long side of the rectangular section is perpendicular to the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com