Pre-twisted spacer

A spacer and pre-twisted technology, applied in the field of spacer, can solve the problems of broken hinges of the clamp body, complicated process, and influence on the performance of the wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present disclosure clearer, the technical solutions of the embodiments of the present disclosure will be clearly and completely described below in conjunction with the accompanying drawings of the embodiments of the present disclosure. In order to maintain the following description of the embodiments of the present disclosure For clarity and conciseness, the present disclosure omits detailed descriptions of known functions and known components to avoid unnecessarily obscuring the concepts of the present invention.

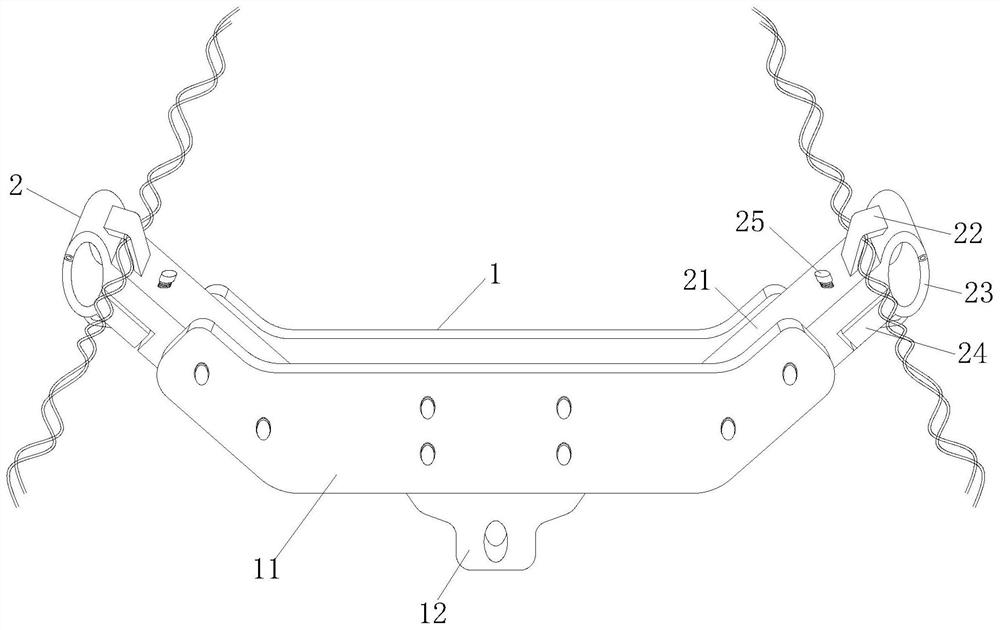

[0023] see figure 1 , a pre-twisted spacer bar, including a support frame 1, a wire clamp 2, and a pre-twisted wire 3, the support frame 1 is composed of two support plates 11 and a connecting piece 12, and the connecting piece 12 is located between two supports Between the boards 11, and between the supporting boards 11 and the connectors 12 are connected by bolts, tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com