A treatment method for controlling the mud and slopping of the subgrade of slab ballastless track railway

A technology of slab ballastless track and mud turning, which is applied to roads, tracks, buildings, etc., can solve the problems of secondary damage of grouting materials, difficult water drainage, etc., so as to improve the stress situation and ensure Fluidity, guarantee the effect of the channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

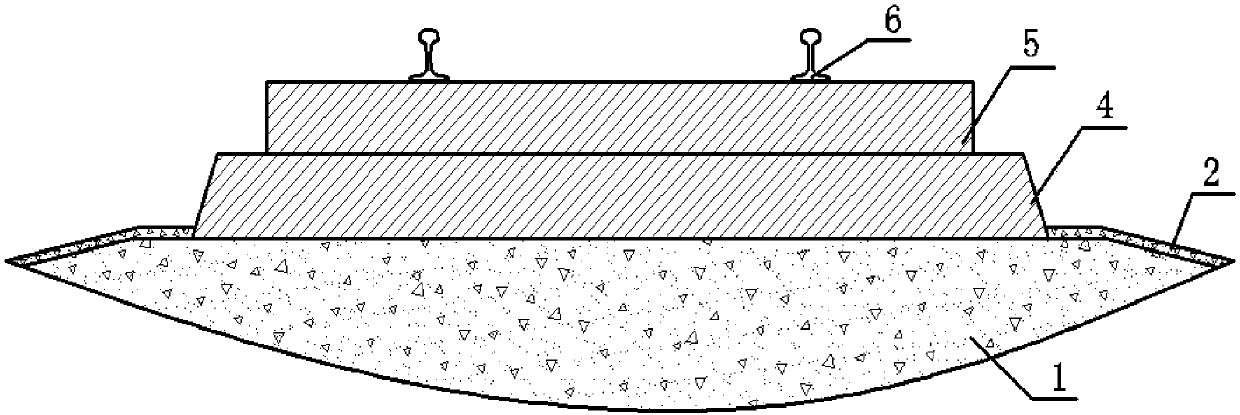

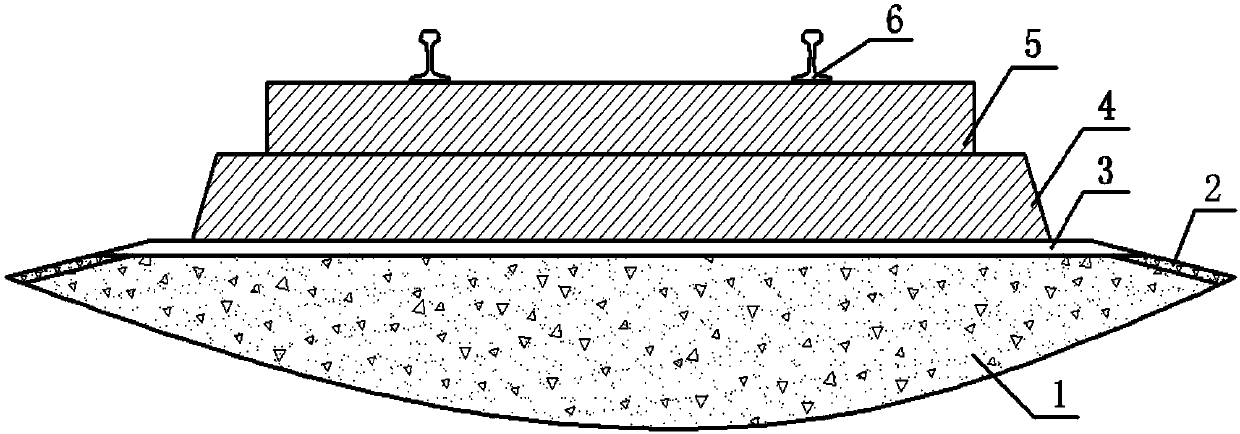

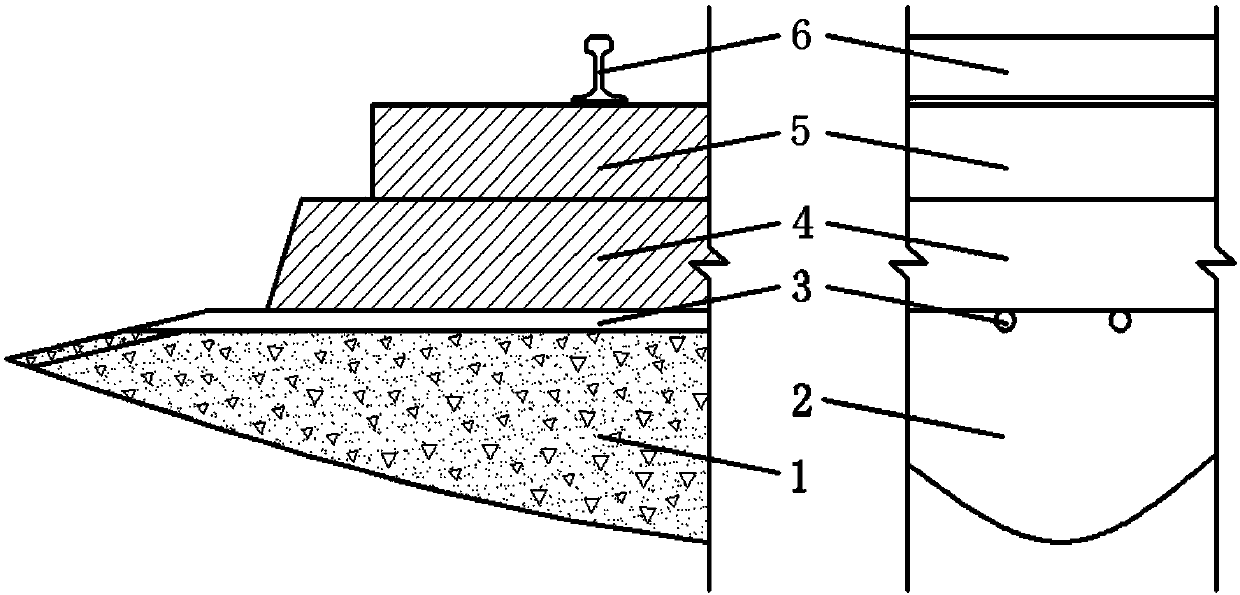

[0031] Such as figure 1 As shown, the structure of the current slab-type ballastless track railway subgrade is that a base plate 4 is laid on the surface layer 1 of the foundation bed, a track plate 5 is laid on the base plate 4, and a rail 6 is laid on the track plate 5; the surface layer 1 of the base bed is covered with a sealing layer 2 , the sealing layer 2 extends to the side edge of the base plate 4 . During the construction of slab ballastless track railway subgrade construction, due to reasons such as poor construction control and construction quality control, the material of the subgrade bed filler (such as mineral composition, plasticity, compressibility, permeability and hydrophilicity, etc.), subgrade compaction, etc. Quality, etc. often cannot meet the design standards of high-speed railway embankment. During the long-term operation of the railway, under the coupling action of complex natural forces and train dynamic cyclic loads, the filling material at the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com