Combined pre-twisted tension-resistant wire clamp

A tension-resistant wire clip and pre-twisted technology, which is applied in the direction of adjusting/maintaining mechanical tension, can solve the problems of difficult control of installation quality, easily damaged steel strands, and easy loosening of strands, etc., to achieve strong installation quality consistency, Not easy to damage and guarantee the effect of normal life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

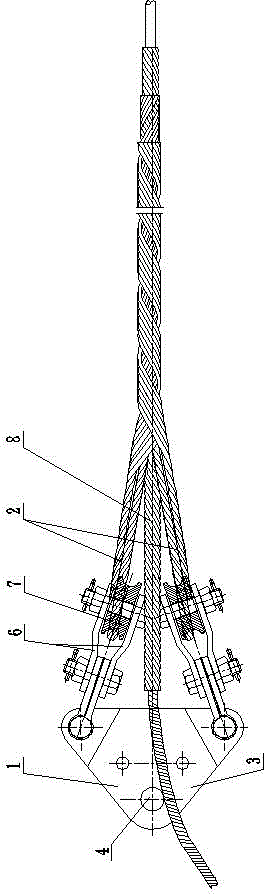

[0008] Such as figure 1 As shown, the present invention includes a connecting device 1 and two sets of pre-twisted wires 2 .

[0009] Connecting device 1 comprises triangular connecting plate 3, and triangular connecting plate 3 is isosceles triangle; The other end of the hanging plate 5 is connected with two connecting plates 6 which do not fit symmetrically. The two connecting plates 6 and the hanging plate 5 are fixedly connected by bolts, and the other ends of the two connecting plates 6 are connected with Rotatable roller 7.

[0010] Each roller 7 is respectively connected with a set of pre-twisted wires 2 , the ends of the pre-twisted wires 2 are folded in half and nested on the rollers 7 , and the rest of the pre-twisted wires 2 are in the shape of a spiral tube.

[0011] When the present invention is actually used, first pass two pre-twisted wires 2 through the corresponding rollers 7 respectively, then wind the rest of the pre-twisted wires 2 evenly on the twisted w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com