Workpiece clamp for numerical control machine tool machining

A technology for processing workpieces and CNC machine tools. It is applied in the direction of manufacturing tools, electric processing equipment, metal processing equipment, etc. It can solve the problems of complexity, high cost of fixtures, troublesome operation and use, etc., to reduce vibration and stress concentration, and to install quickly. Convenience, anti-vibration and slipping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

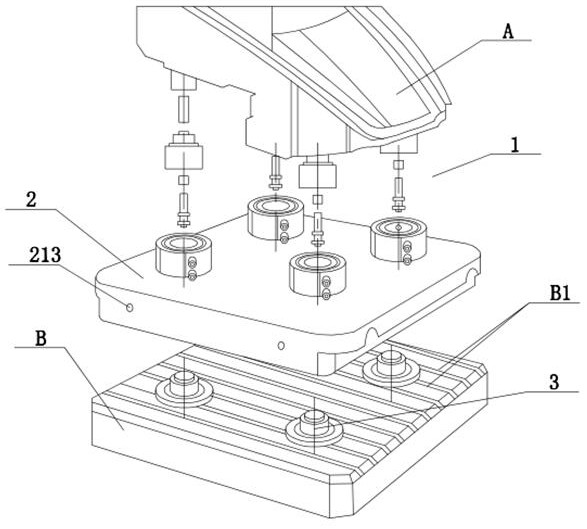

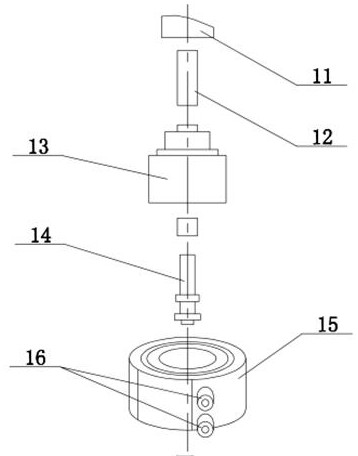

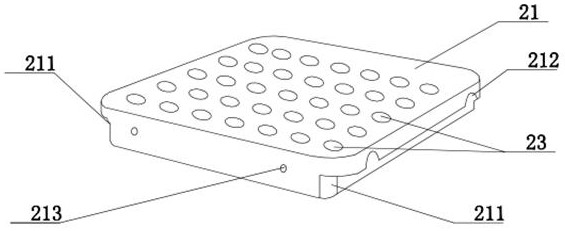

[0021] see Figure 1-Figure 10 As shown, this specific embodiment includes a workpiece mounting part 1, a connector base 2, and a base connector 3. The top of the workpiece mounting part 1 is inserted into the bottom of the workpiece A to be processed, and the bottom of the workpiece mounting part 1 is fixed on the connector base. 2, the connector base 2 is fixed on the machine bed B through the base connector 3; the workpiece mounting part 1 includes a connecting central shaft 11, a central guide column 12, an expansion ring 13, a base fixing column 14, and an outer The ring 15, the locking hole 16 of the connector, the upper part of the connecting central shaft 11 is fixed on the processed workpiece A, the connecting central shaft 11 is fixedly connected on the central guide post 12, the central guide post 12 is fixed in the expansion ring 13, and the expansion ring 13 is arranged in the outer ring 15 of the connector, and the outer ring 15 of the connector is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com