Preparation method of high-strength Zr-Ti-based alloy

A high-strength alloy-based technology, applied in the field of powder metallurgy, can solve problems such as poor density of Zr-Ti-based alloys, segregation of Zr-Ti-based alloy components, shrinkage and porosity of structures, etc., and achieve high density, low production cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of Zr-Ti base alloy, comprises the following steps:

[0027] After mixing the Zr powder and the Ti powder, a mixed powder is obtained;

[0028] The mixed powder is subjected to cold isostatic pressing to obtain a molded green body;

[0029] The shaped body is sintered to obtain a Zr-Ti based alloy.

[0030] In the present invention, mixed powder is obtained after Zr powder and Ti powder are mixed.

[0031] In the present invention, the mass ratio of the Zr powder to the Ti powder is preferably 1:99˜99:1, more preferably 80:1˜1:80, further preferably 60:1˜1:60. In the present invention, the particle diameters of the Zr powder and the Ti powder are independently preferably 5-45 μm, more preferably 10-30 μm.

[0032] In the present invention, the mixed powder preferably further includes a trace amount of metal powder. In the present invention, the trace metal powder preferably includes one or more of Cr powder, V powd...

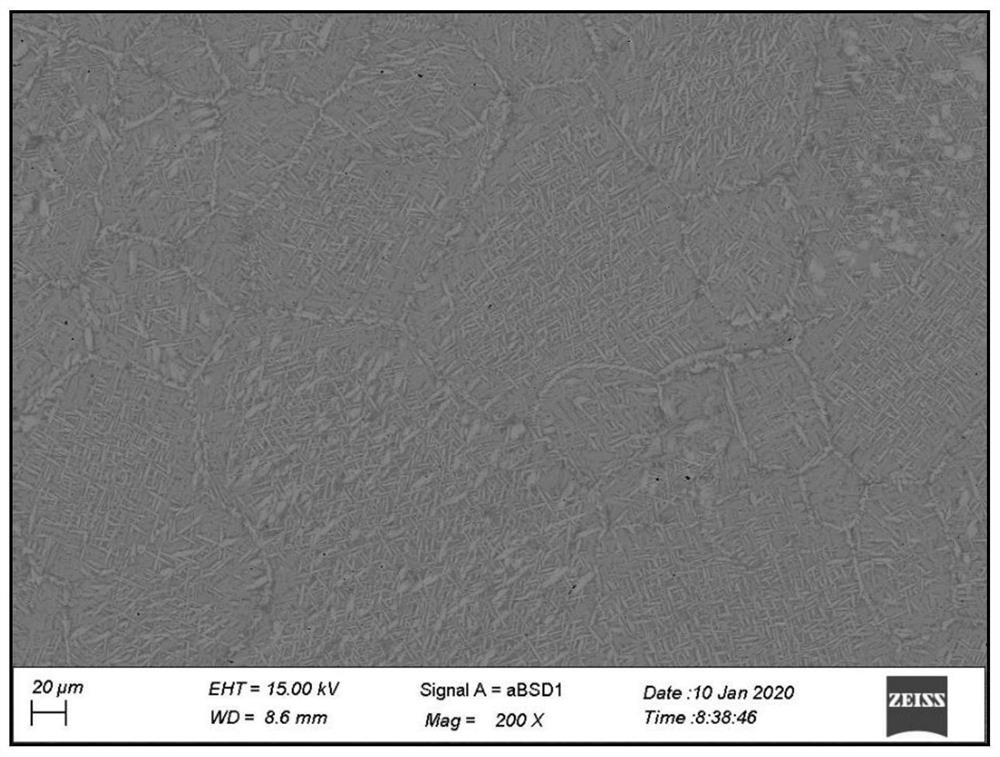

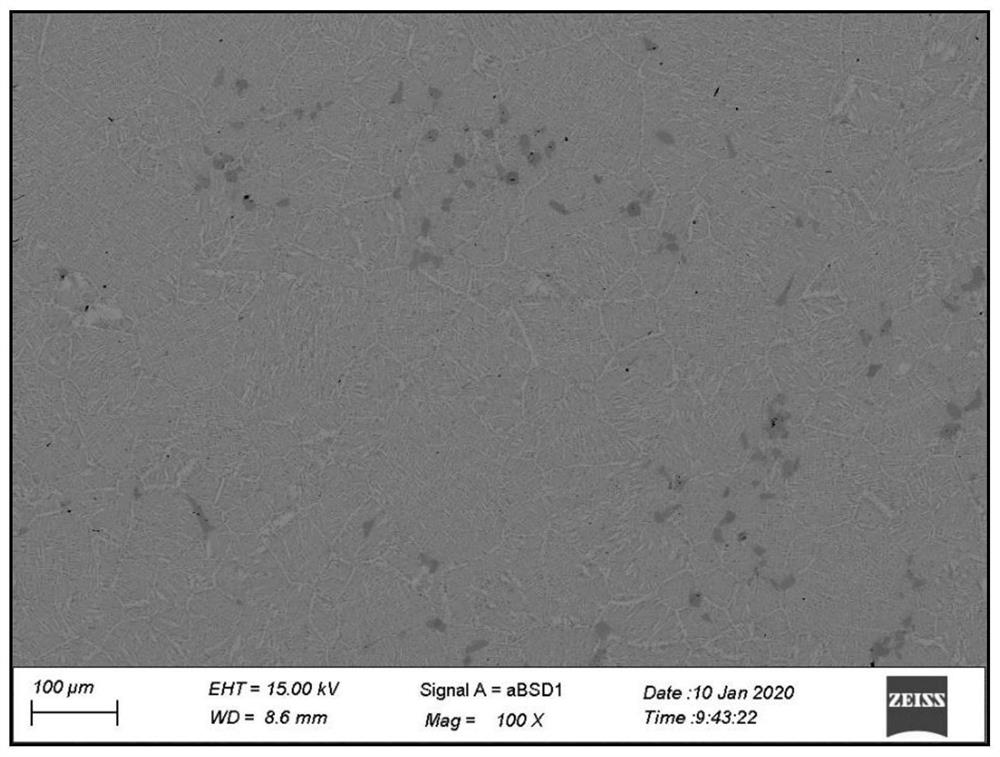

Embodiment 1

[0047] Weigh Zr powder with a particle size of 10 μm, Ti powder with a particle size of 10 μm and Co powder with a particle size of 10 μm, wherein the mass ratio of Zr powder to Ti powder is 4:1, and the amount of Co powder added accounts for 1% of the total mass. %. The above powder is ball milled on a planetary ball mill, the ball milling medium is absolute ethanol, the volume ratio of the total volume of Zr powder and Ti powder to absolute ethanol is 1:2, and the dispersant is Tween-80, Tween-80 The mass is 0.2wt.% of the total mass of the Zr powder and the Ti powder, the ball milling speed is 200r / min, the ball milling time is 6h, the ball-to-material ratio is 3:1, and the diameter of the ball is 10mm to obtain the mixed material;

[0048] Dry the mixed material in a vacuum drying oven at a temperature of 30°C for 5 hours to obtain a mixed powder;

[0049] The obtained mixed powder is pressed into shape by a cold isostatic pressing process, the pressure is 200MPa, and the...

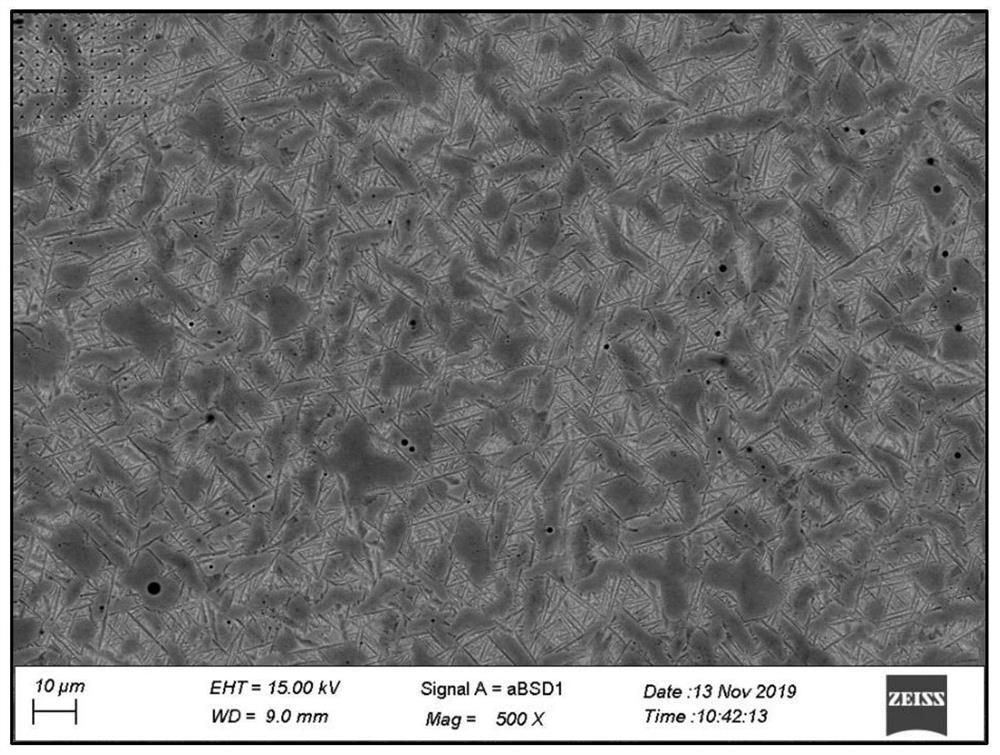

Embodiment 2

[0053] Weigh Zr powder with a particle size of 10 μm and Ti powder with a particle size of 10 μm, wherein the mass ratio of Zr powder and Ti powder is 9:1, and the above powder is ball milled on a planetary ball mill, and the ball milling medium is absolute ethanol, The volume ratio of the total volume of Zr powder and Ti powder to absolute ethanol is 1:3, the dispersant is Tween-80, the quality of Tween-80 is 0.3wt.% of the total mass of Zr powder and Ti powder, ball milling The rotating speed is 250r / min, the ball milling time is 9h, the ball-to-material ratio is 3:1, and the diameter of the ball is 10mm to obtain the mixed material;

[0054] Dry the mixed material in a vacuum drying oven at a temperature of 30°C for 5 hours to obtain a mixed powder;

[0055] The obtained mixed powder is pressed into shape by cold isostatic pressing process, the pressure is 250MPa, and the pressure holding time is 35min, to obtain the formed green body;

[0056] Put the obtained molded body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com