An anti-biofouling coating based on a primary cell with a micron-sized bimetallic laminate structure and its preparation method

A double metal layer, anti-biological technology, applied in metal material coating process, metal processing equipment, coating, etc., can solve the problems of short service life, limited anti-fouling effect, toxic raw materials of anti-biofouling coating, etc. , to achieve the effect of avoiding galvanic corrosion, preventing passivation, long-term stability and anti-biofouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

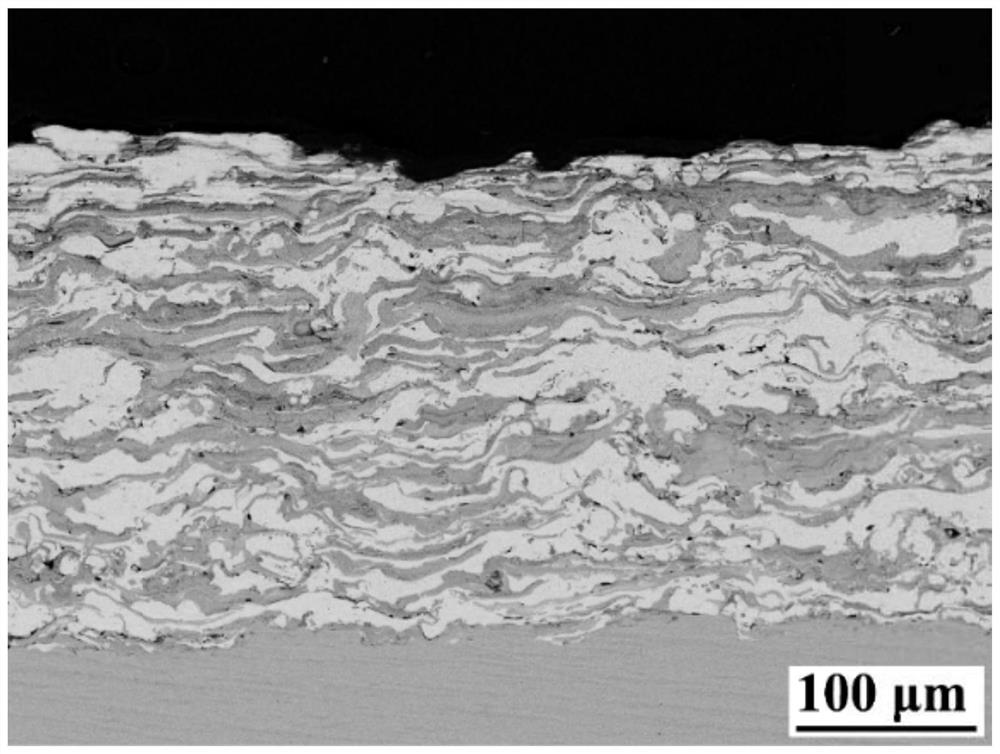

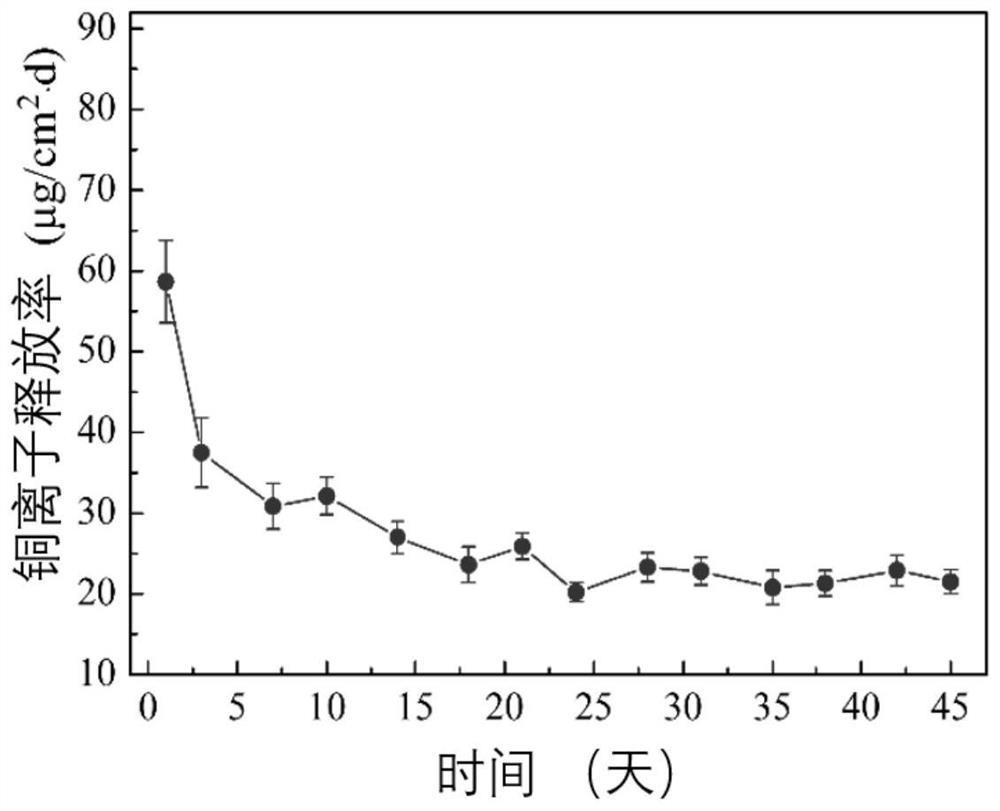

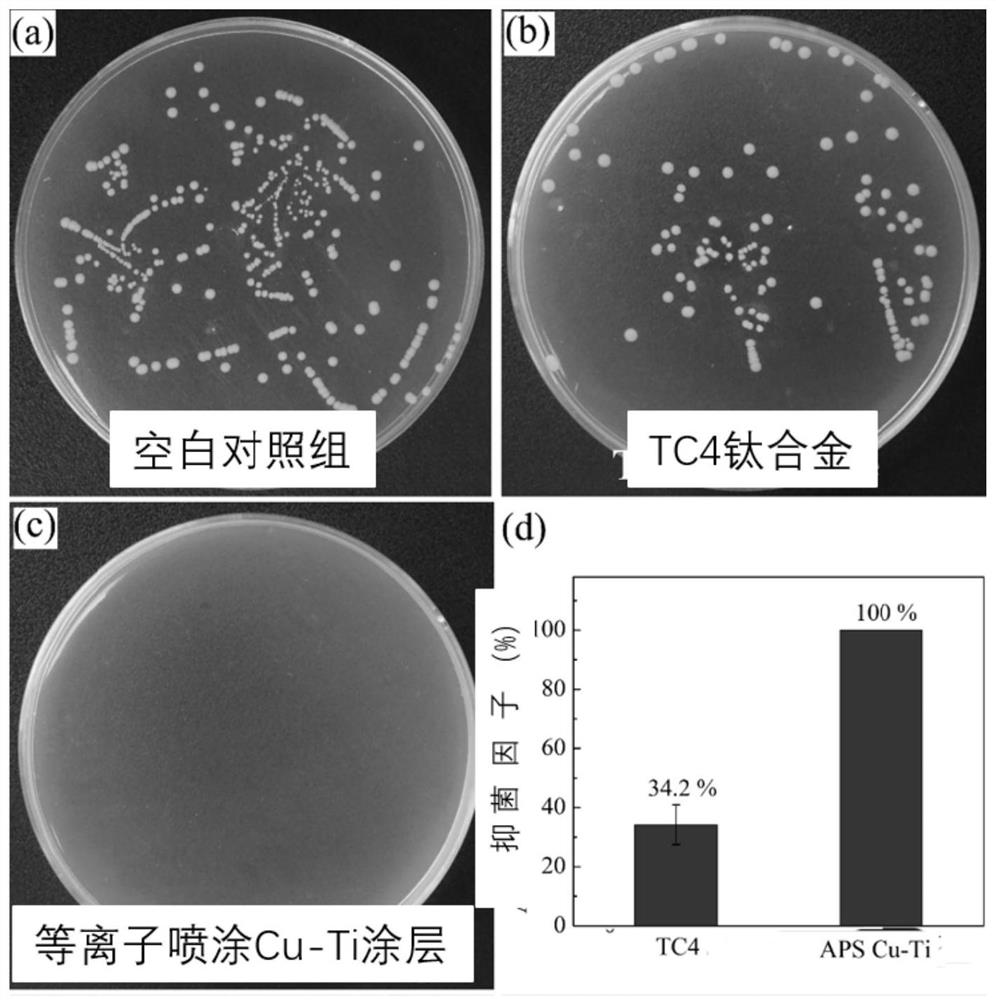

Embodiment 1

[0040] Copper powder with a particle size distribution of 30-100 microns and titanium powder with a particle size distribution of 15-75 microns are used as raw materials, and the two powders are fully mixed with a drum mixer, and the volume content of the copper powder is 50 %, the drum speed is set to 60rpm, the powder mixing time is 60 minutes, and the mixed powder is used as the spraying material. TC4 titanium alloy is used as the base material, and the surface of the base material is cleaned and roughened by sandblasting process before coating preparation, and the surface roughness after treatment is Ra 4.5-6.5 microns. Atmospheric plasma spraying is used for coating preparation, the mixed gas of argon and hydrogen is used as the plasma gas, nitrogen is used as the powder feeding gas, the spraying power is 32kW, the spraying distance is 100mm, the powder feeding rate is 40g / min, and the moving speed of the spray gun is 500mm / s, the thickness of the coating is 0.3mm.

[0...

Embodiment 2

[0043] Copper powder with a particle size distribution of 10-50 microns and stainless steel with a particle size distribution of 15-45 microns are used as raw materials, and the two powders are fully mixed with a drum mixer. The volume ratio of copper powder and stainless steel powder The ratio is 1:4, the rotation speed of the drum is set to 60rpm, the powder mixing time is 60 minutes, and the mixed powder is used as the spraying raw material. With stainless steel as the base material, the surface of the base material is cleaned and roughened by sand blasting process before coating preparation, and the surface roughness after treatment is Ra 4.5-6.5 microns. The coating is prepared by cold spraying, nitrogen is used as the working gas, the gas temperature is 500°C, the gas pressure is 3.0MPa, the spraying distance is 35mm, the powder feeding rate is 100g / min, and the gun speed is 300mm / s. Thickness 2.5mm.

[0044] The result is as Figure 4 As shown in (a) and (b), the char...

Embodiment 3

[0046] Copper powder with a particle size distribution of 15-50 microns and tin bronze powder with a particle size distribution of 15-45 microns are used as raw materials, and the two powders are fully mixed with a drum mixer. The volume ratio is 1:1, the rotation speed of the drum is set to 60rpm, and the powder mixing time is 60 minutes. The mixed powder is used as the spraying raw material. The marine steel is used as the substrate. Before the coating is prepared, the surface of the substrate is cleaned and roughened by sandblasting. The surface roughness after treatment is Ra 4.5-6.5 microns. Supersonic flame spraying is used for coating preparation, oxygen and kerosene are used as working fuels, nitrogen is used as powder feeding gas, the spraying power is 32kW, the spraying distance is 350mm, the powder feeding rate is 75g / min, and the moving speed of the spray gun is 1000mm / s. The thickness of the coating is 0.2 mm.

[0047] The result is as Image 6 As shown, there a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com