Anti-cracking calcium silicate board and preparation process thereof

A calcium silicate board and a preparation technology, which is applied in the field of calcium silicate board, can solve problems affecting the performance of calcium silicate board, blanking, delamination, cracks, human health hazards, etc., to achieve human and environmental friendliness, Good crack growth and improved thermal expansion coefficient matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

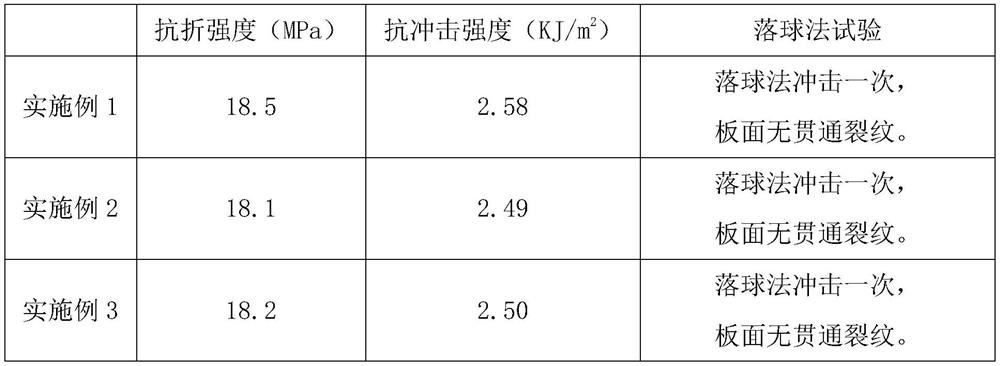

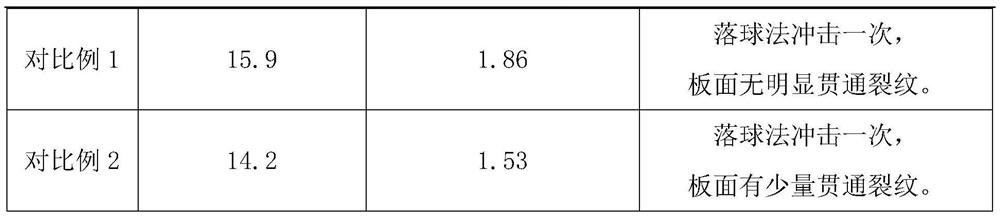

Examples

Embodiment 1

[0023] An anti-cracking calcium silicate board made of raw materials of the following quality: 35kg of alkali slag, 6kg of slaked lime, 14kg of cement, 22kg of quartz powder, 1.5kg of yttria-stabilized zirconia, 0.5kg of sodium polyacrylate, and β-eucryptite Glass fiber 4kg, pulp 6kg, anhydrous sodium sulfate 2kg.

[0024] The β-eucryptite glass fiber is made of the following raw materials in parts by weight: 9 parts of β-eucryptite, 37 parts of quartz sand, 18 parts of kaolin, 2 parts of soda ash, 2 parts of calcium oxide, and 1 part of magnesium oxide. The method is: take β-eucryptite, quartz sand, kaolin, soda ash, calcium oxide, and magnesium oxide and mix them into a high-temperature kiln for melting at 1200°C to obtain molten glass, then cool the molten glass to 850°C and then draw wire to form a Glass fiber filaments of 6-12mm are soaked in acetone and hydrochloric acid solutions, washed and dried.

[0025] A preparation process for the anti-cracking calcium silicate b...

Embodiment 2

[0030] An anti-cracking calcium silicate board made of raw materials of the following quality: 30kg of alkali slag, 4kg of slaked lime, 12kg of cement, 20kg of quartz powder, 1kg of yttria-stabilized zirconia, 0.3kg of sodium polyacrylate, and β-eucryptite glass Fiber 3kg, pulp 5kg, anhydrous sodium sulfate 1kg.

[0031] The β-eucryptite glass fiber is made of the following raw materials in parts by weight: 8 parts of β-eucryptite, 35 parts of quartz sand, 15 parts of kaolin, 2 parts of soda ash, 1 part of calcium oxide, and 1 part of magnesium oxide. The method is: take β-eucryptite, quartz sand, kaolin, soda ash, calcium oxide, and magnesium oxide and mix them into a high-temperature kiln for melting at 1100°C to obtain molten glass, then cool the molten glass to 800°C and then draw wire to form a Glass fiber filaments of 6-12mm are soaked in acetone and hydrochloric acid solutions, washed and dried.

[0032] A preparation process for the anti-cracking calcium silicate boar...

Embodiment 3

[0037] An anti-cracking calcium silicate board made of raw materials of the following quality: 40kg of alkali slag, 8kg of slaked lime, 16kg of cement, 24kg of quartz powder, 2kg of yttria-stabilized zirconia, 0.7kg of sodium polyacrylate, and β-eucryptite glass Fiber 6kg, pulp 7kg, anhydrous sodium sulfate 3kg.

[0038] The β-eucryptite glass fiber is made of the following raw materials in parts by weight: 10 parts of β-eucryptite, 40 parts of quartz sand, 20 parts of kaolin, 3 parts of soda ash, 2 parts of calcium oxide, and 2 parts of magnesium oxide. The method is: take β-eucryptite, quartz sand, kaolin, soda ash, calcium oxide, and magnesium oxide and mix them into a high-temperature kiln for melting at 1300°C to obtain molten glass, then cool the molten glass to 900°C and then draw wire to form a Glass fiber filaments of 6-12mm are soaked in acetone and hydrochloric acid solutions, washed and dried.

[0039] A preparation process for the anti-cracking calcium silicate b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com