Near ultraviolet excited red fluorescent powder and preparation method thereof

A technology of red phosphor and near-ultraviolet light, which is applied in the direction of luminescent materials, chemical instruments and methods, electrical components, etc., can solve the problems of phosphor not being environmentally friendly and red light impurity, and reduce dipole-dipole interaction , avoid concentration quenching, and increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: La 2 SeO 6 :0.2Eu 3+

[0017] Weigh La with a purity greater than 99.9% according to the stoichiometric ratio 2 o 3 , SeO 2 and Eu 2 o 3 The raw materials, will be weighed raw materials mixed thoroughly. Then the mixed powder was placed in a crucible and pre-fired at 200°C for 3 hours. After pre-calcination, the calcined powder was ground again and calcined in air at 1000°C for 18h. After naturally cooling to room temperature, the obtained powder was ground again to obtain the phosphor powder.

Embodiment 2

[0018] Example 2: La 2 SeO 6 :0.1Eu 3+

[0019] Weigh La with a purity greater than 99.9% according to the stoichiometric ratio 2 o 3 , SeO 2 and Eu 2 o 3 The raw materials, will be weighed raw materials mixed thoroughly. Then the mixed powder was placed in a crucible and pre-fired at 500°C for 1 hour. After pre-calcination, the calcined powder was ground again and calcined in air at 1200°C for 6h. After naturally cooling to room temperature, the obtained powder was ground again to obtain the phosphor powder.

Embodiment 3

[0020] Example 3: La 2 SeO 6 :0.15Eu 3+

[0021] Weigh La with a purity greater than 99.9% according to the stoichiometric ratio 2 o 3 , SeO 2 and Eu 2 o 3 The raw materials, will be weighed raw materials mixed thoroughly. The mixed powder was then placed in a crucible and pre-fired at 400°C for 2 hours. After pre-calcination, the calcined powder was ground again and calcined in air at 1100°C for 13h. After naturally cooling to room temperature, the obtained powder was ground again to obtain the phosphor powder.

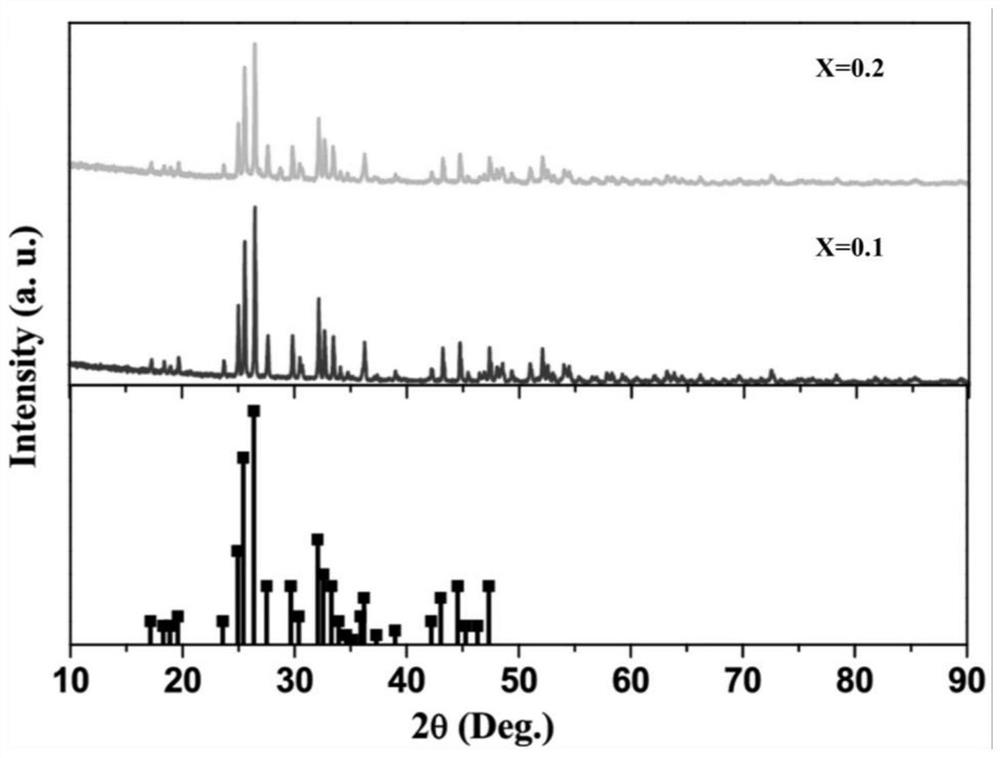

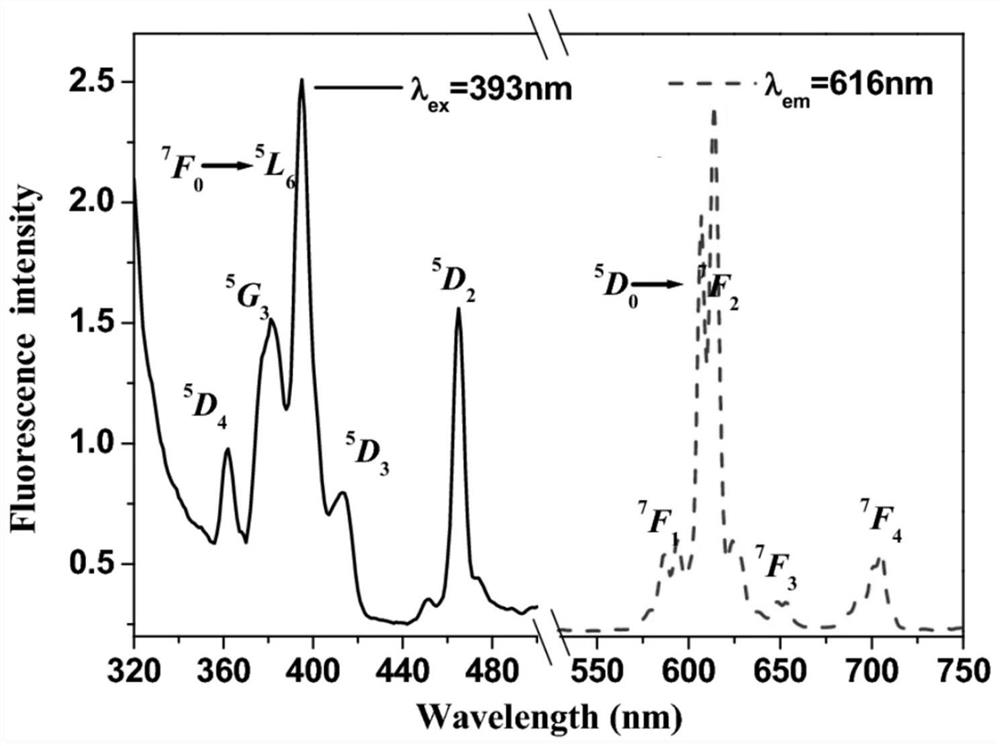

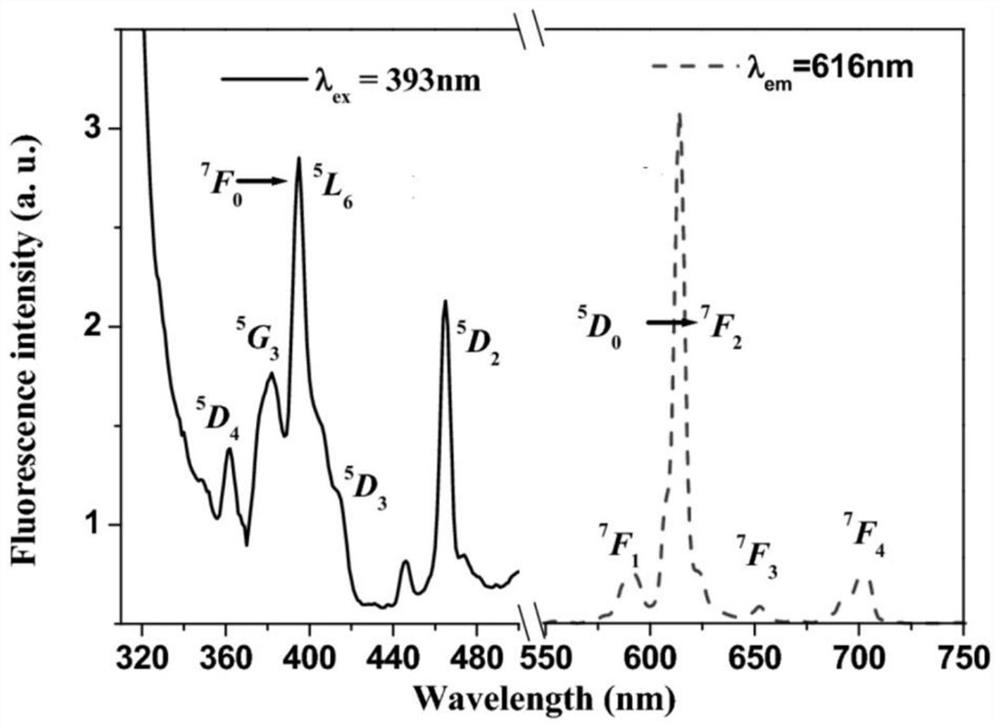

[0022] Depend on figure 1 The XRD collection of patterns shows, taking embodiment 1,2 as example, by and La 2 SeO 6 The comparison of the standard diffraction peaks can be seen that the method provided by the invention successfully synthesizes and pure La 2 SeO 6 :Eu 3+ Phosphor. according to figure 2 , 3 The excitation and emission spectra of the phosphor powders show that the phosphor powders prepared in Example 1 and Example 2 emit strong red l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com