Metal lithium battery negative electrode, preparation method thereof and lithium secondary battery

A battery negative electrode and metal lithium technology, which is applied in the field of metal lithium battery negative electrode and lithium secondary battery, can solve the problems of capacity retention, cycle life, low energy density, etc., and achieve the promotion of lithium ion crossing and good compatibility , The effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a method for preparing a metal lithium battery negative electrode, comprising the following steps:

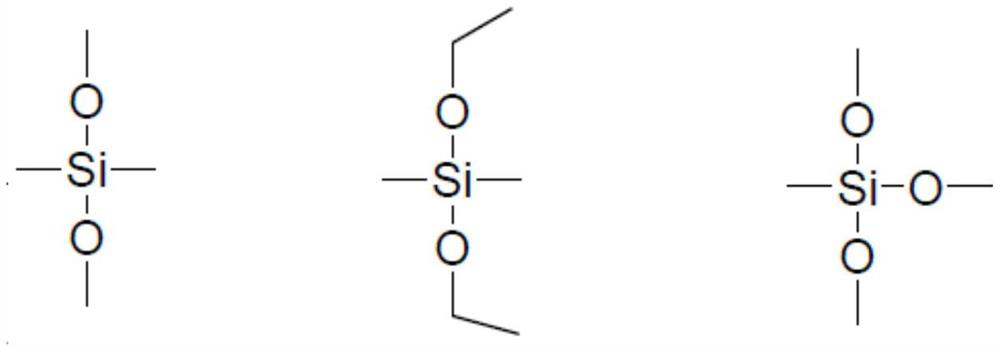

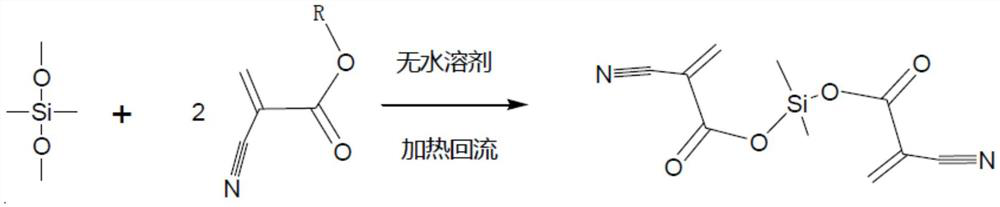

[0022] a) under anhydrous conditions, the silane coupling agent and cyanoacrylate are transesterified in an anhydrous solvent to obtain a solution containing transesterified products;

[0023] b) coating the solution containing the transesterification product on the surface of the negative electrode foil and drying to obtain a negative electrode containing a protective layer.

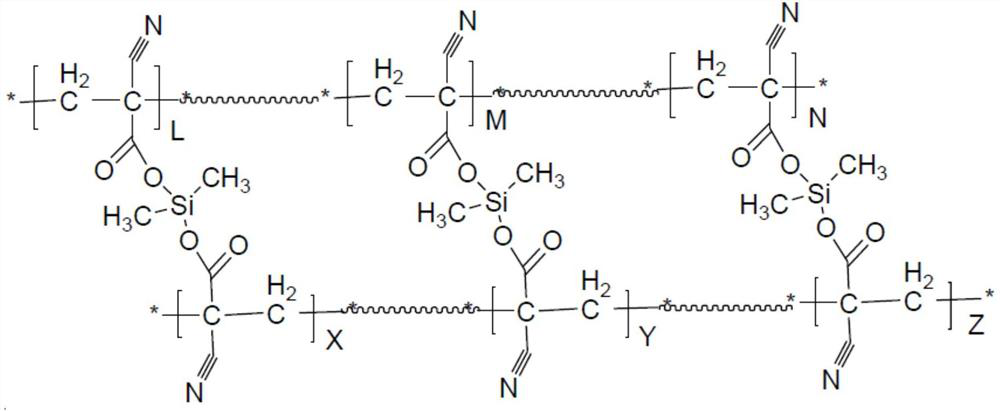

[0024] In the present invention, a specific silane coupling agent is transesterified with cyanoacrylate to form a transesterified product, which is coated on the surface of the negative electrode foil. After coating, anionic polymerization is initiated by Li or a small amount of water in the air. Make the transesterification product form a spatially cross-linked polymer. The cross-network polymer coating can effectively promote the penetration of lithium ions, induce lithium...

Embodiment 1

[0051] S1. Under the protection of nitrogen, dimethyldimethoxysilane and methyl cyanoacrylate were successively dissolved in NMP, heated to 120° C., stirred and refluxed for 8 hours, and transesterified to obtain a solution containing transesterified products.

[0052] S2. After cooling to room temperature, the above solution containing the transesterification product is coated on the surface of the metal lithium foil, the thickness of the foil is 50 μm, and the coating thickness of the solution is 60 μm.

[0053] S3. Dry the coated foil at 80° C. for 10 h, and then carry out processes such as rolling and cutting to prepare a negative electrode sheet. The pole piece is a disc with a diameter of 15 mm, and the obtained negative electrode is denoted as C1.

Embodiment 2

[0055] The negative electrode was prepared according to the preparation process of Example 1, except that dimethyldimethoxysilane was replaced by dimethyldiethoxysilane, and the obtained negative electrode was denoted as C2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Capacity | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com