Yarn pattern printing method

A printing method and yarn technology, applied in the field of spinning, to achieve the effect of upgrading grades, large design space, and avoiding twisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

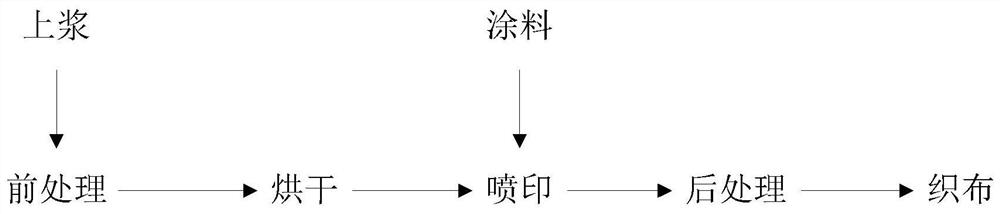

[0051] as attached figure 1 Shown, the yarn pattern printing method of the present invention, the method is specifically as follows:

[0052] S1. Pre-treatment: sizing the threaded yarn to ensure that the subsequent process can weave printed pattern yarn;

[0053] S2. Drying: after sizing, dry the yarn;

[0054] S3, spray printing: after drying, the yarn is spray-printed by ink-jet printing technology;

[0055] S4. Post-processing: after spray printing, fix the color of the yarn;

[0056] S5. Weaving: After fixing the color, the yarn enters the normal weaving process.

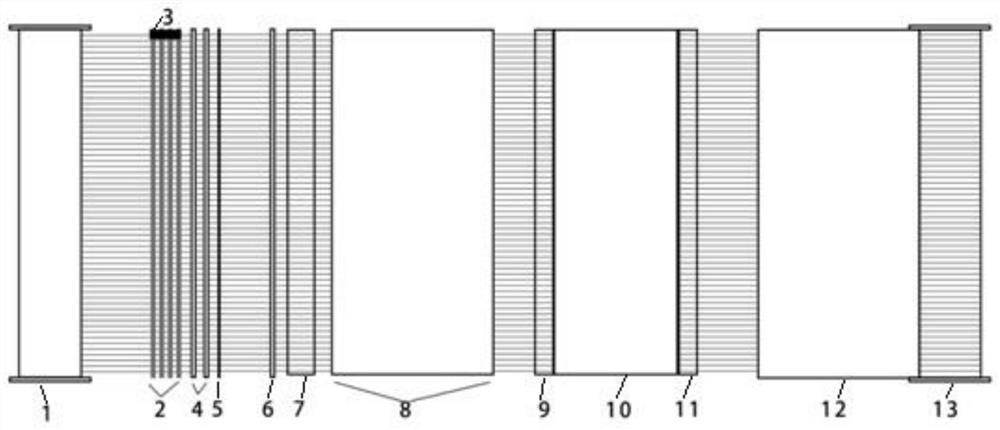

[0057] as attached figure 2As shown, the pre-processing in step S1 in this embodiment is specifically as follows:

[0058] S101, the yarn after drafting enters the warp beam 1;

[0059] S102. After the yarn passes through the warp beam 1, the yarn carding is completed after passing through the warp dropper 2, the palm frame 4 and the reed 5;

[0060] S103, the carded yarn enters the sizing tank 7 under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com