Edible oil production and processing equipment

A processing equipment and edible oil technology, applied in the direction of fat oil/fat production, fat generation, cleaning methods and utensils, etc., can solve the problems of poor impurity removal effect, low cleaning efficiency, high labor intensity, etc., to achieve good effect and improve The effect of edible oil quality and efficiency of impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

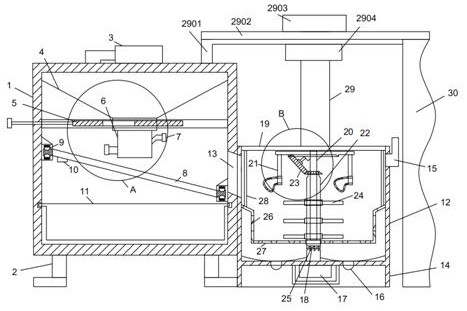

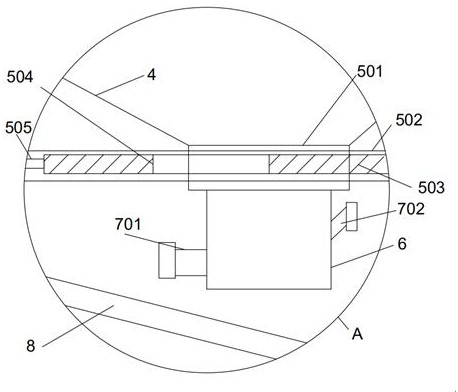

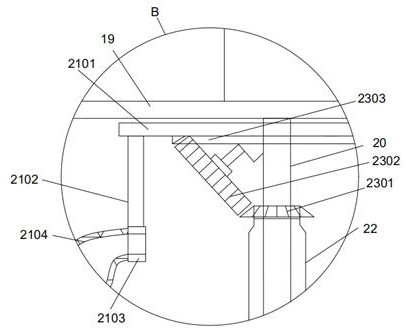

[0033] see figure 1 , a kind of edible oil production and processing equipment, comprises impurity removal machine box 1, and the bottom of described impurity removal machine case 1 is fixedly installed with support leg 2, and the top of described impurity removal machine box 1 is fixedly installed with lifting pump 3, and described impurity removal machine box 1 is fixedly installed with a collection bucket 4 at the top, the bottom of the collection bucket 4 is fixed with a flow limiting device 5, the bottom of the flow limiting device 5 is fixed with a falling flat tube 6, and the side of the falling flat tube 6 is fixed A miscellaneous suction device 7 is installed, and the inner middle part of the miscellaneous removal cabinet 1 is fixedly equipped with a miscellaneous removal filter screen 8, and the two ends of the described miscellaneous removal filter screen 8 are fixedly installed with a clamping device 9, and the described miscellaneous removal filter screen 8 The bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com