Preparation method of transformer oil base oil

A transformer oil and base oil technology, applied in chemical instruments and methods, catalyst activation/preparation, base materials, etc., can solve the problems of high price, high molecular sieve content, high catalyst cost, etc., to reduce production costs and improve utilization , the effect of low pour point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

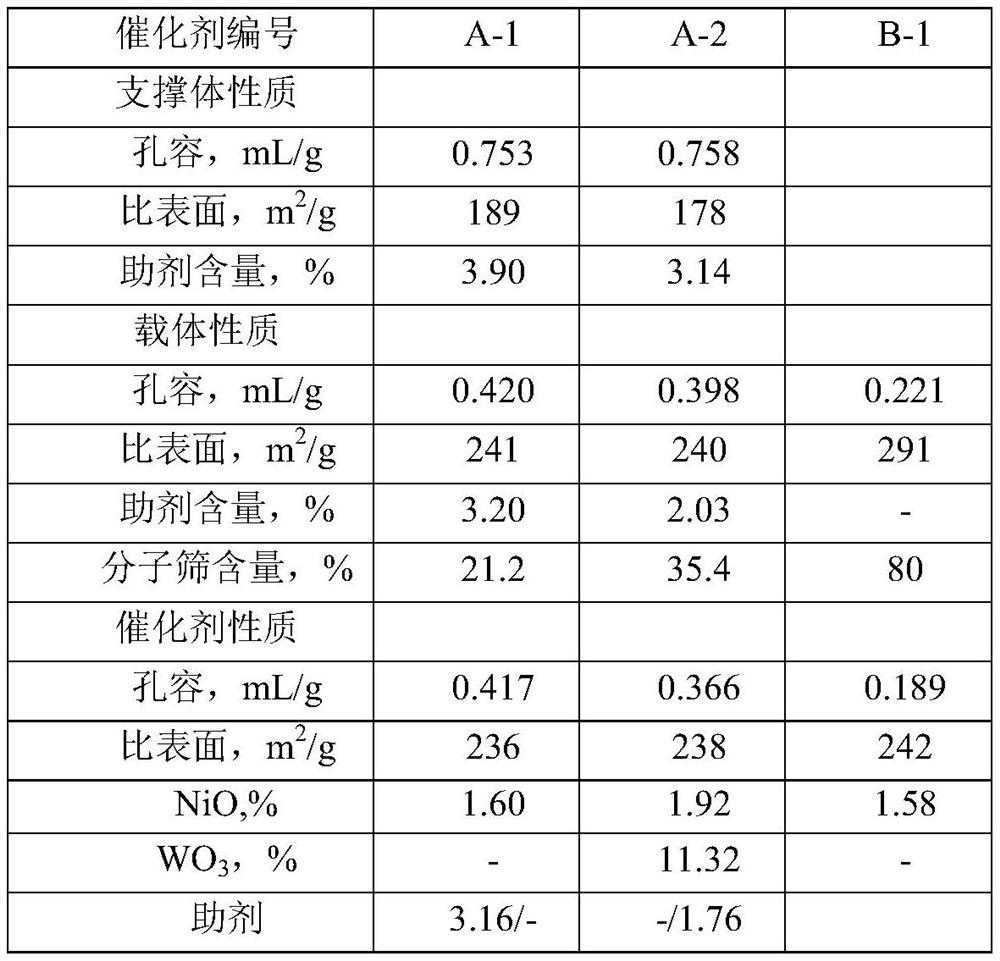

Examples

Embodiment 1

[0064] Weigh the pore volume 1.095mL / g and the specific surface area 328m3 produced by the aluminum sulfate method respectively. 2 Add 500g of pseudo-boehmite 500g of dry basis 71%, 18.4g of nitric acid of concentration 65%, 10g of scallop powder, 71g of carbon black, 60g of nickel nitrate auxiliary agent and 754g of deionized water into the roller compactor and roll and mix , extruded into a cylindrical bar with an outer diameter of 6 mm and an inner hollow diameter of 2.5 mm, and dried the bar to a solid content of 65% under conditions of constant humidity and constant temperature.

[0065] Use punching equipment to punch circular through-holes with a diameter of 1.5mm uniformly arranged on the surface of the cylindrical strip, and make particles with a length of 3mm to 10mm. After drying at 130°C for 8h, bake at 900°C for 3h to get carrier support. body.

[0066] Weigh 7.52g of aluminum sulfate, 320g of silica sol containing 30% of silicon oxide, 2.15g of sodium hydroxide,...

Embodiment 2

[0069] Weigh the pore volume 1.095mL / g and the specific surface area 328m3 produced by the aluminum sulfate method respectively. 2 Add 18.4g of nitric acid 18.4g, 10g of squid powder, 89g of starch, 43.7g of copper nitrate trihydrate auxiliary agent and 754g of deionized water into the roller compactor and grind 500g of pseudo-boehmite with 71% dry basis, 18.4g of nitric acid with a concentration of 65%. Press and mix, extrude into a cylindrical bar with an outer diameter of 6 mm and an inner hollow diameter of 2.5 mm, and dry the bar to a solid content of 65% under constant humidity and constant temperature conditions.

[0070] Use punching equipment to punch circular through-holes with a diameter of 1.5mm uniformly arranged on the surface of the cylindrical strip, and make particles with a length of 3mm to 10mm. After drying at 130°C for 8h, bake at 900°C for 3h to get carrier support. body.

[0071] Weigh 15.53g of aluminum sulfate, 663g of silica sol containing 30% of sil...

Embodiment 3

[0079] A 200mL reactor device was used to conduct a pilot test, and the diesel fraction of a hydrogenation upgrading unit in a factory was used as a raw material (see Table 2 for the properties of the raw material). Transformer oil with a pour point less than -50°C. According to the flow direction of the reaction materials, the special-shaped support body containing the spinel structure and the shape-selective cracking molecular sieve membrane hydrogen depreciation catalyst and a certain amount of SiO are loaded sequentially. 2 Alumina-supported supplementary refined catalysts.

[0080] Wherein, the hydrodecondensation catalyst of the hydrodecondensation reactor is the catalyst prepared in Example 1 and Example 2.

[0081] The supplementary refining catalyst in the hydrogenation supplementary refining reaction zone is based on SiO 2 9wt% γ-Al 2 o 3 is the carrier, W-Mo-Ni is the active component, P is the promoter, and the WO in the catalyst 3 Content is 22wt%, MoO 3 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com