A blue light inp/zns quantum dot and its preparation method and application in qled

A technology of quantum dots and blue light, applied in the field of preparation of blue light InP/ZnS quantum dots, can solve the problems of instability limitation of perovskite quantum dots, poor device performance, etc., achieve low lattice mismatch, improve quality, Reduce the effects of nonradiative recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

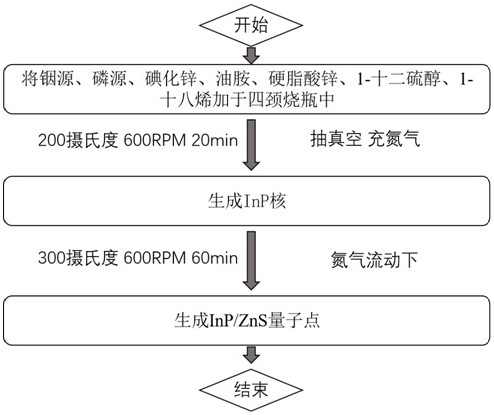

[0018] A method for synthesizing blue light InP / ZnS quantum dots, the specific preparation steps are:

[0019] A kind of synthetic method of blue light InP / ZnS quantum dot, indium source, phosphorus source, zinc iodide, oleylamine, zinc stearate, 1-dodecanthiol, 1-octadecene are placed in the flask of 50ml, The phosphorus source includes P[N(CH3)2]3, (DMA)3P, TMS3P, the indium source is InCl3, InI3, In(OAc)3, In(Ac)3, and the ratio of phosphorus source to indium source is 5:1 . Then first vacuumize for 30 minutes, remove the air in the flask as much as possible, then feed nitrogen at 100 degrees Celsius for 20 minutes, quickly increase the temperature of the liquid in the flask to 200 degrees Celsius, reach the reaction temperature of the phosphorus source and the indium source, and react for 20 minutes. The lnp nucleus whose size just emits pure blue light below 470nm is generated. Then rapidly increase the temperature to 300 degrees Celsius to reach the reaction temperatur...

Embodiment 2

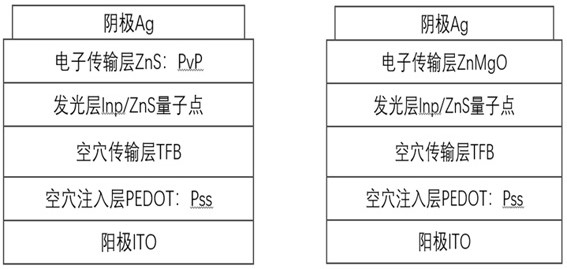

[0021] figure 2 It is the device structure diagram of QLED of the present invention

[0022] The device structure is: ITO / PEDOT:PSS / TFB / InP QD / ETL / Ag

[0023] Specific implementation: The device substrate is selected as a glass substrate, and then the substrate containing the anode layer ITO is ultrasonically cleaned with acetone, isopropanol, and deionized water in sequence, dried, and plasma treated. The hole injection layer is spin-coated, the hole injection layer is PEDOT:PSS, the hole transport layer is TFB, and it is formed by spin coating. The annealing temperature of the hole injection layer and the hole transport layer is 120 degrees Celsius. The time is 20 minutes, the rotational speed during spin coating is 3000 rpm, and the spin coating time is 40 s. As the light-emitting layer of the device, InP / ZnS quantum dots can be prepared by spin coating and inkjet printing. The advantage of the spin coating process is that it is relatively simple to operate, while the ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com