Precursor solution of hydrophilic lubricating coating and application of precursor solution to preparation of surface coating of medical instrument

A technology of lubricating coatings and medical devices, applied in the preparation of surface coatings of medical devices, in the field of precursor liquid of hydrophilic lubricating coatings, can solve problems such as shedding, blood vessel blockage, side effects, etc., and achieve good biocompatibility , Improve rejection, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

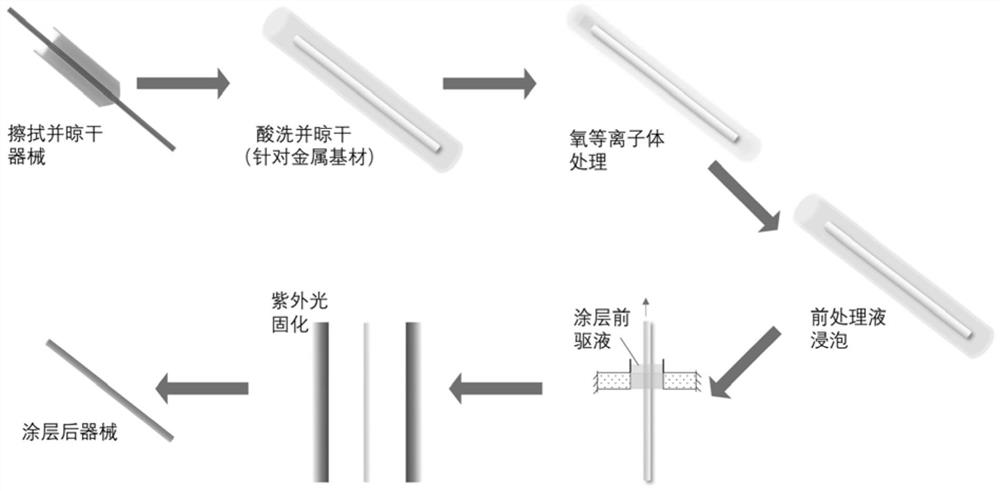

[0067] A kind of hydrophilic lubricating coating for Pebax (polyether block polyamide) guide wire surface, its preparation method is as follows:

[0068] (1) Polyvinylpyrrolidone (model Sigma-Aldrich#PVP360, molecular weight is about 360000) with a mass fraction of 13% and benzophenone with a mass fraction of 0.5% are uniformly dissolved in water and ethanol (volume ratio is 1:1 ) in the mixed solution to obtain the precursor solution of the hydrophilic lubricating coating;

[0069] (2) Clean the surface of the Pebax guide wire with isopropanol, ethanol and water in sequence, and let it dry for 3 minutes;

[0070] (3) Oxygen plasma treatment was carried out on the guide wire for 1 min, and then further soaked in an aqueous solution of 1% trimethoxy (propyl) silane by mass fraction for 60 min to activate the surface;

[0071] (4) The precursor solution obtained in step (1) is coated on the surface of the Pebax guide wire after step (3) by the dipping method, and the pulling sp...

Embodiment 2

[0074] This embodiment provides a hydrophilic lubricating coating for the surface of a stainless steel guide wire, the preparation method of which is as follows:

[0075] (1) The polyethylene glycol (model is Supelco 81206, molecular weight is about 218000) that the mass fraction is 10% and the benzophenone that the mass fraction is 0.2% are dissolved in water and ethanol (volume ratio is 1.2:1) In the mixed solution, the precursor solution of hydrophilic lubricating coating is obtained;

[0076] (2) Clean the surface of the stainless steel guide wire with isopropanol and water successively, and after drying for 5 minutes, place it in an acid wash containing 20% hydrochloric acid and 5% hydrogen peroxide for 20 minutes, take it out, and dry it for 5 minutes;

[0077] (3) Oxygen plasma treatment was carried out to the guide wire for 20 min, and then further soaked in a mixed solution of 2% 3-(trimethoxysilyl) propyl methacrylate and ethanol for 90 min to make it Surface acti...

Embodiment 3

[0081] This embodiment provides a hydrophilic lubricating coating for the surface of a stainless steel guide wire, the preparation method of which is as follows:

[0082] (1) Agarose (model is Sigma-Aldrich#A1296) with a mass fraction of 5% and coumarone with a mass fraction of 2% are uniformly dissolved in a mixed solution of water and ethanol (volume ratio of 1.2:1), Obtain the precursor solution of hydrophilic lubricating coating;

[0083] (2) Clean the surface of the stainless steel guide wire with isopropanol and water successively, and after drying for 1 min, place it in an acid wash containing 20% hydrochloric acid and 5% hydrogen peroxide for 20 min, take it out, and dry it for 5 min;

[0084] (3) Carry out oxygen plasma treatment 3min to guide wire, further soak 30min in the mixed solution of water and ethanol of 3-(trimethoxysilyl) propyl methacrylate that mass fraction is 4%, make it Surface activation, wherein the volume ratio of water to ethanol is 9:1;

[008...

PUM

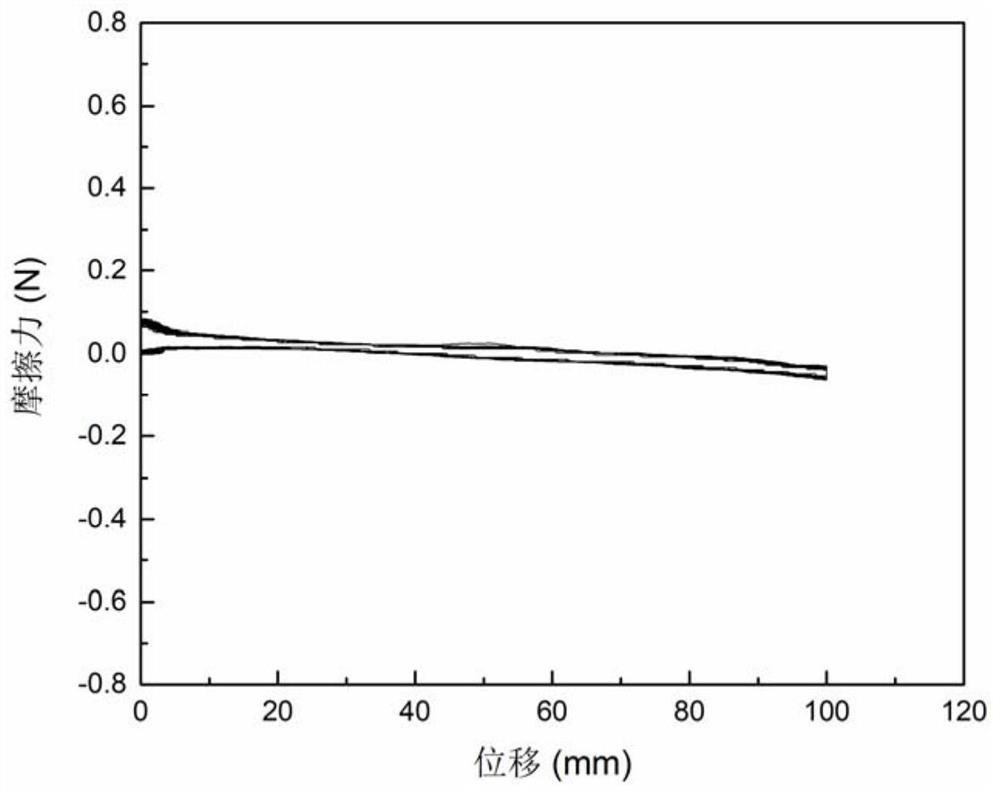

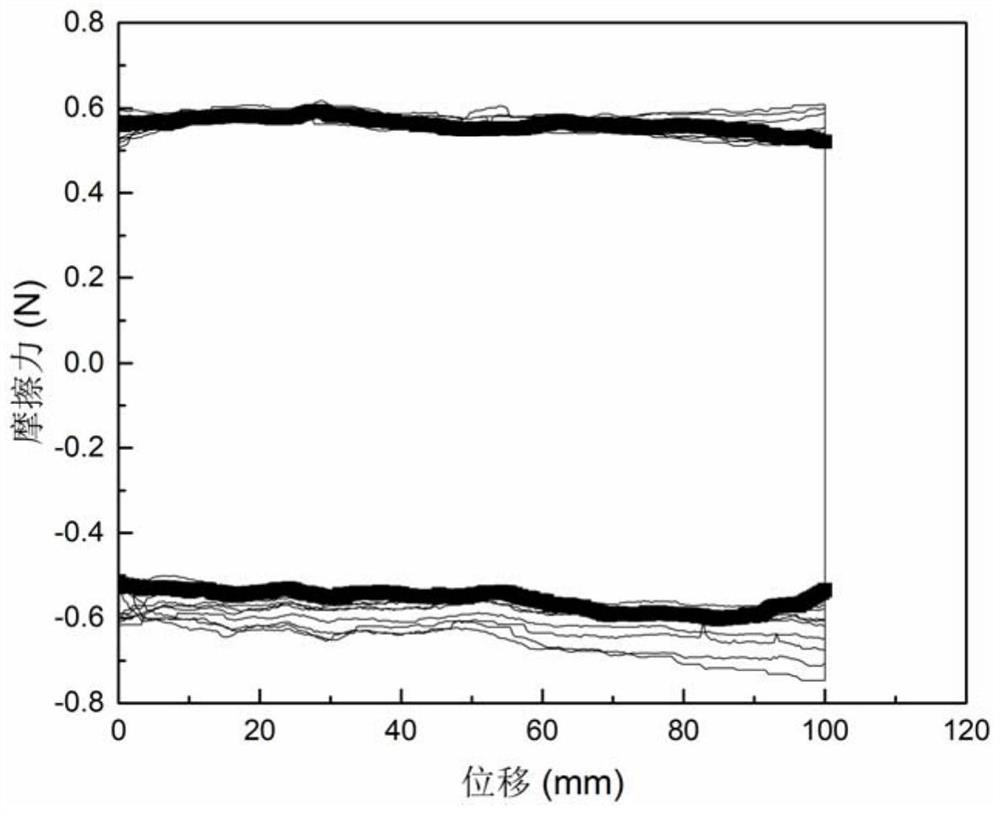

| Property | Measurement | Unit |

|---|---|---|

| friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com