Method and equipment for continuously synthesizing rubber vulcanization accelerator S

A technology of vulcanization accelerator and synthetic rubber, applied in the field of continuous synthetic rubber vulcanization accelerator, can solve the problems of volatile raw materials, waste of raw materials, inability to guarantee quality stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This example provides the structure of a continuous reaction device.

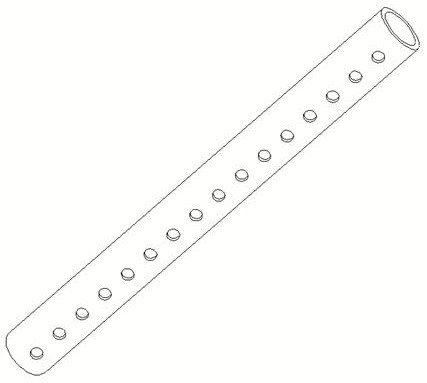

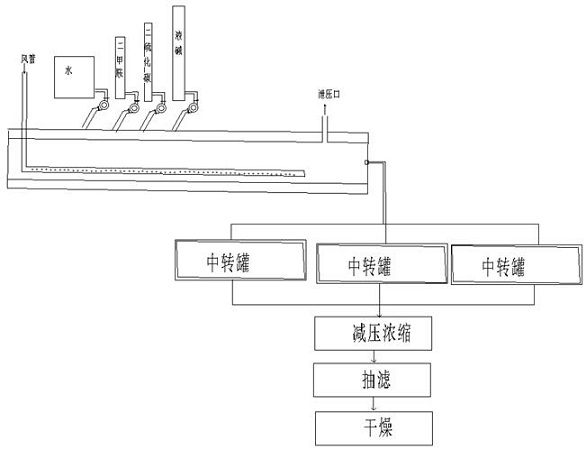

[0028] A device for continuously synthesizing rubber vulcanization accelerator S, including a device body, the device body includes a tubular reactor, the tubular reactor is installed horizontally, and a blast pipeline is arranged above the front end of the reactor inlet, and the blast pipeline Go deep into the bottom of the reactor vertically, and lay flat on the bottom of the reactor, and evenly distribute the air outlet holes on the blast pipe at the bottom of the reactor. Feed rate design, present embodiment is a row. The outermost end of the inlet of the tubular reactor is closed ( figure 2 The leftmost end of the middle reactor), the outlet end ( figure 2 The rightmost end of the middle reactor) is provided with a circular overflow port in the middle; the upper end of the second half of the reactor is connected with a vent valve pipeline, which is connected to the tail gas absorption device...

Embodiment 2

[0035] This example provides a method for continuously synthesizing the rubber vulcanization accelerator S.

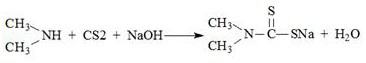

[0036] Use a graduated cylinder to measure 30ml of water, 115ml of dimethylamine aqueous solution with a mass fraction of 40%, 57ml of carbon disulfide with a mass fraction of 98% (add a small amount of water for liquid sealing to reduce volatilization), and 81ml of an aqueous sodium hydroxide solution with a mass fraction of 32%. , put into four custom-made glass beakers with glass outlets and switches at the bottom, and the steam pipes are put into the glass beakers where the water is placed, to heat the water and keep the temperature between 40-45 °C, and insert a thermometer at the same time Measurement. The remaining raw materials are charged at room temperature. Before adding the raw materials, turn on the blower; when adding the raw materials, first drop 30ml of water, the peristaltic pump speed is 7.6 rpm, then add 115ml of dimethylamine, and the peristaltic p...

Embodiment 3

[0041] On the basis of the conditions in Example 2, the feed rate of the raw materials was increased to carry out the feed reaction.

[0042] When the temperature of the reaction system is 25-45°C, turn on the blower, turn on 57ml of water in turn, the peristaltic pump speed is 28.8 rpm, 218.5ml dimethylamine, the peristaltic pump speed is 98.0 rpm, 108.3ml carbon disulfide, the peristaltic pump speed is 49.4 rpm Minutes, 153.9ml liquid caustic soda, peristaltic pump speed 69.2 rpm, the above four materials are added dropwise to the tubular reactor according to the above dosage and peristaltic pump speed.

[0043] The liquid flowing out of the tubular reactor is the accelerator S, which is a light yellow liquid with no peculiar smell, a specific gravity of 1.070g / ml, and no waste carbon. The liquid accelerator S was concentrated under reduced pressure at a temperature of 30°C. After 45 minutes, after all the crystals were precipitated, it was filtered with suction to obtain 24...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com