Manufacturing process of anti-fragmentation raw glass sheet

A manufacturing process and anti-fragmentation technology, applied in glass manufacturing equipment, manufacturing tools, glass production and other directions, can solve the problems of wear resistance, easily broken, easy to cut workers and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

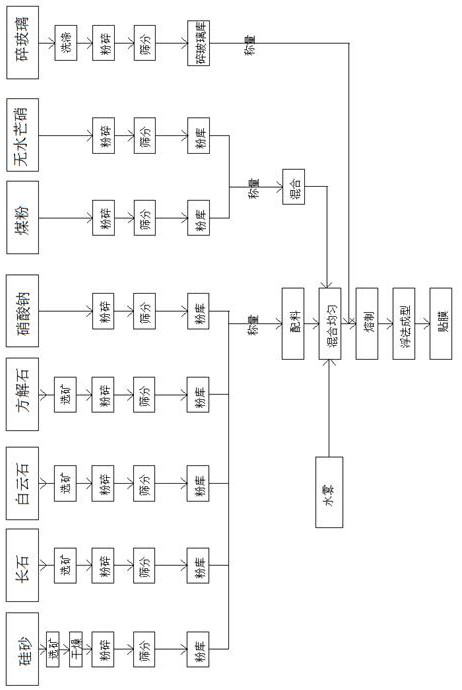

Method used

Image

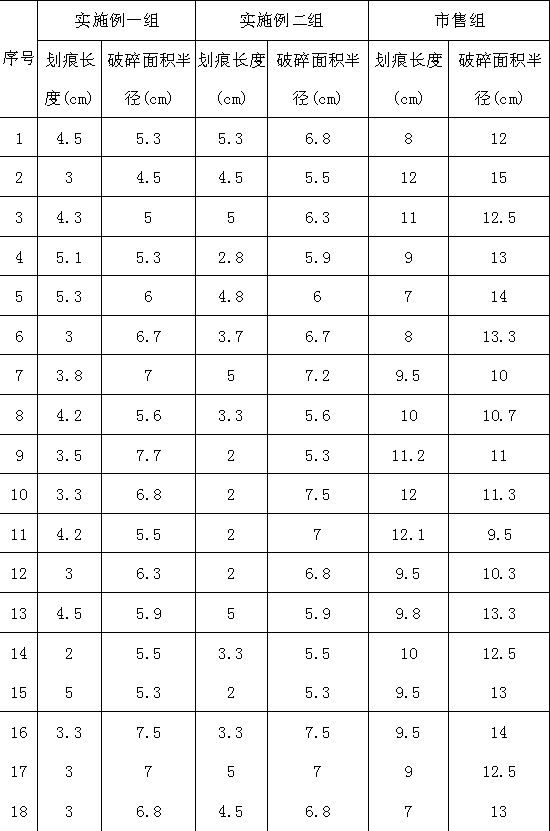

Examples

Embodiment 1

[0029] A method for manufacturing an anti-shatter glass original sheet proposed by the present invention, comprising the following raw materials: including the following raw material weight percentages: 75% of silica sand, 5% of feldspar, 7% of anhydrous Glauber's salt, and 4% of anhydrous Glauber's salt for coal powder , dolomite 6%, calcite 7%, sodium nitrate is 12% of anhydrous Glauber's salt, cullet is 20% of the total weight of raw materials.

[0030] Its production process includes the following steps:

[0031] S1. Raw material treatment: first send the silica sand to the drying room for drying, then crush the silica sand, feldspar, dolomite and limestone with the impact crusher and the Kunming crusher respectively, and then sieve with the mechanical vibrating screen and send them into the Flour storehouse, standby, anhydrous Glauber's salt and coal powder are crushed with cage mill respectively, standby;

[0032] S2. Ingredients: according to the original weight parts ...

Embodiment 2

[0039] A kind of manufacturing method of anti-shatter glass original piece that the present invention proposes, comprises following raw material: Comprising following raw material percentage by weight: silica sand 72%, feldspar 8%, anhydrous Glauber's salt 7%, coal powder is 4% of anhydrous Glauber's salt , dolomite 6%, calcite 7%, sodium nitrate is 10% of anhydrous Glauber's salt, cullet is 25% of the total weight of raw materials.

[0040] Its production process includes the following steps:

[0041] S1. Raw material treatment: first send the silica sand into the drying room for drying, then crush the silica sand, feldspar, dolomite and limestone with the impact crusher and the Kunming pulverizer respectively, and then sieve with the mechanical vibrating screen before sending them into the Flour storehouse, standby, anhydrous Glauber's salt and coal powder are crushed with cage mill respectively, standby;

[0042] S2. Ingredients: According to the original weight parts as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com