Electronic glass with high liquidus viscosity and preparation method

A liquidus, glass technology, applied in glass manufacturing equipment, glass molding, glass molding and other directions, can solve problems such as affecting production stability, reducing temperature difference, and small liquidus viscosity of glass, achieving beneficial results. It is used for overflow down-draw molding, which can meet the effect of stable production and reduce production difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

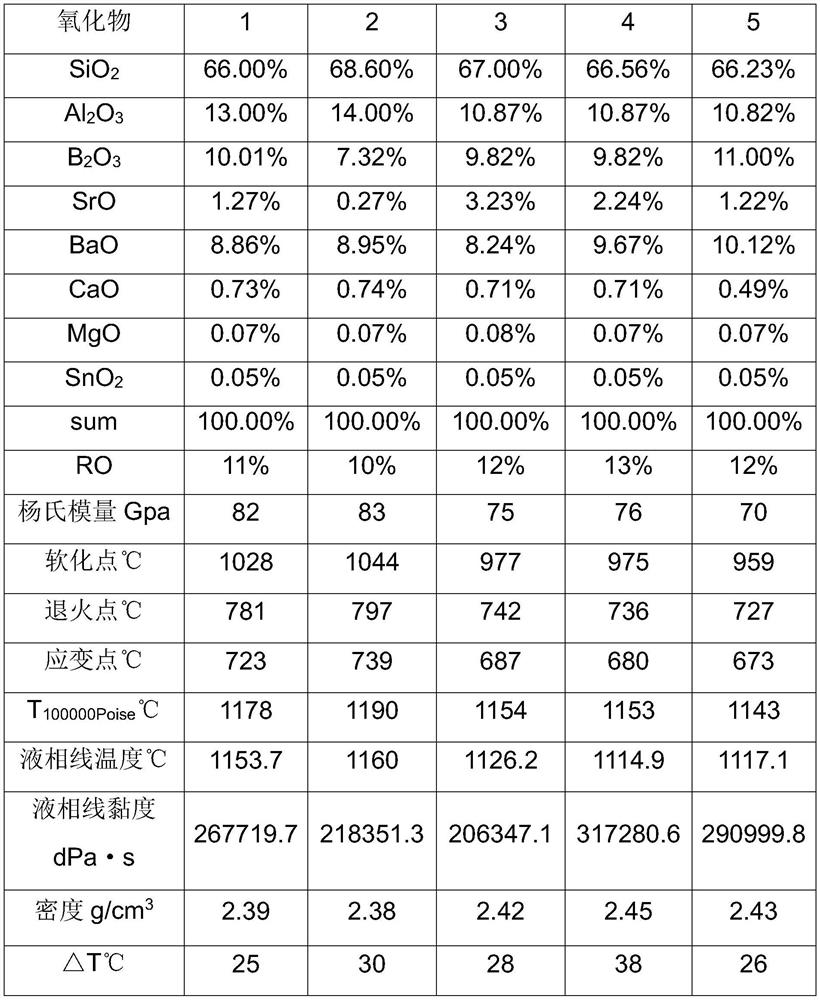

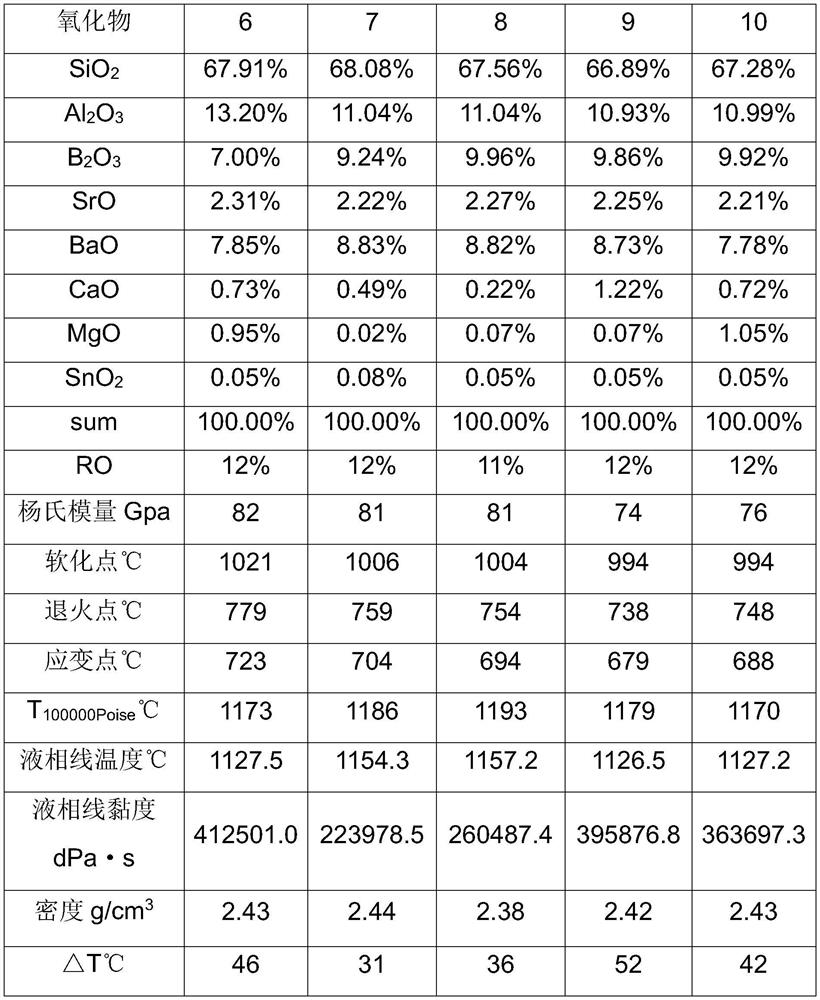

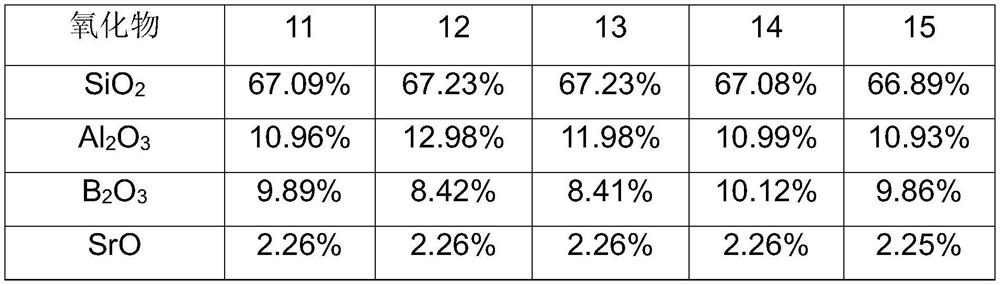

[0039] A preparation method of electronic glass with high liquidus viscosity of the present invention comprises the following steps:

[0040] Step 1: Pour the raw materials into the mixer and mix them evenly to form a mixture; the ratio of the raw materials is: SiO 2 : 65.56-68.6%; Al 2 O 3 : 10.58-14%; B 2 O 3 : 7-11%; SrO: 0.27-3.26%; BaO: 7.20-10.12%; CaO: 0.22-1.22%; MgO: 0-1.05%.

[0041] MgO+CaO+SrO+BaO<13%.

[0042] In step 2, the mixture of step 1 is put into the glass furnace, heated to melt the glass, and after the glass is melted, it enters the platinum feeding channel for clarification to make glass melt.

[0043] In step 3, the glass melt is formed into an electronic glass with a high liquidus viscosity by a down-draw method; the liquidus viscosity is more than 200,000 poise.

Embodiment 1

[0045] A preparation method of electronic glass with high liquidus viscosity, comprising the following steps:

[0046] Step 1, pour the raw materials into the mixer and mix them evenly to form a mixture; the ratio of the raw materials expressed in mole percentage is: SiO 2 : 66.00%; Al 2 O 3 : 13.00%; B 2 O 3 : 10.01%; SrO: 1.27%; BaO: 8.86%; CaO: 0.73%; MgO: 0.07%.

[0047] MgO+CaO+SrO+BaO<13%.

[0048] Step 2, add the mixture of step 1 into the glass furnace, heat to melt the glass, and after the glass is melted, it enters the platinum feed channel for clarification to make glass melt, and SnO is added during clarification. 2 : 0.05%.

[0049] In step 3, the glass melt is formed into an electronic glass with a high liquidus viscosity by a down-draw method; the liquidus viscosity is 267719.7 poise.

[0050] The strain point temperature Ts of the electronic glass in Example 1 is 723°C; the Young's modulus is 82MPa; the density is 2.39g / cm 3 , the liquidus temperature o...

Embodiment 2

[0052] A preparation method of electronic glass with high liquidus viscosity, comprising the following steps:

[0053] Step 1, pour the raw materials into the mixer and mix them evenly to form a mixture; the ratio of the raw materials expressed in mole percentage is: SiO 2 : 68.60%; Al 2 O 3 : 14.00%; B 2 O 3 : 7.32%; SrO: 0.27%; BaO: 8.95%; CaO: 0.74%; MgO: 0.07%.

[0054] MgO+CaO+SrO+BaO<13%.

[0055] Step 2, add the mixture of step 1 into the glass furnace, heat to melt the glass, and after the glass is melted, it enters the platinum feed channel for clarification to make glass melt, and SnO is added during clarification. 2 : 0.05%.

[0056] In step 3, the glass melt is formed into an electronic glass with high liquidus viscosity by the down-draw method; the liquidus viscosity is 218351.3 poise.

[0057] The strain point temperature Ts of the electronic glass in Example 2 is 739°C; the Young's modulus is 83MPa; the density is 2.38g / cm 3 , the liquidus temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com