Battery-grade iron phosphate, preparation method and application thereof

An iron phosphate, battery-level technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of high enterprise cost, complicated process, environmental pollution, etc., and achieve less impurity content, lower impurity content, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

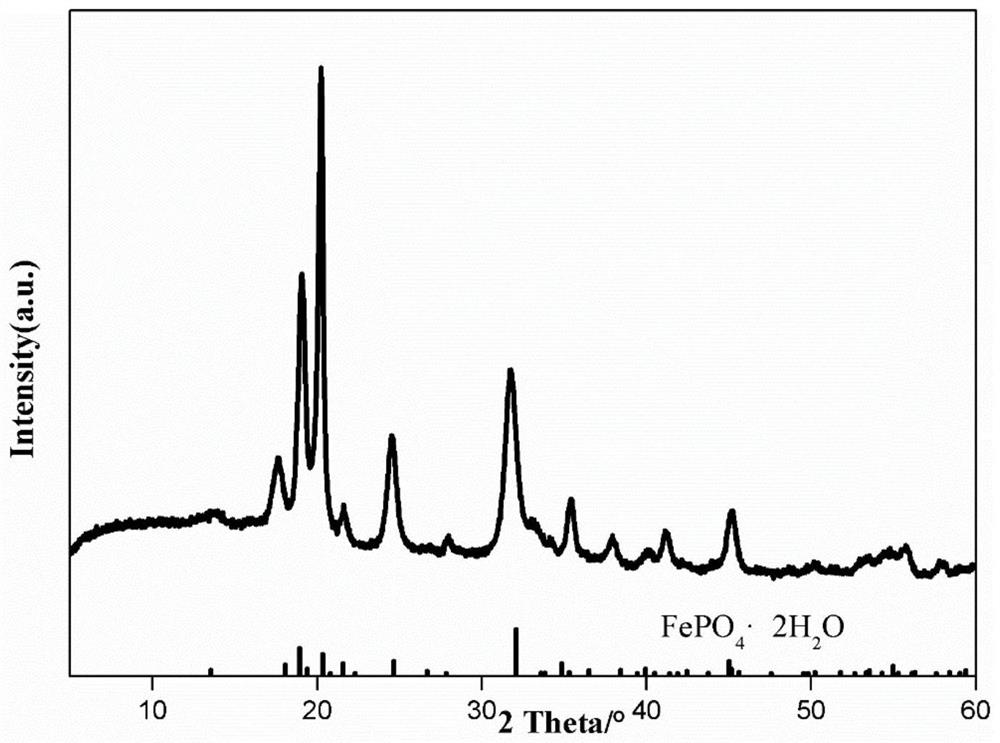

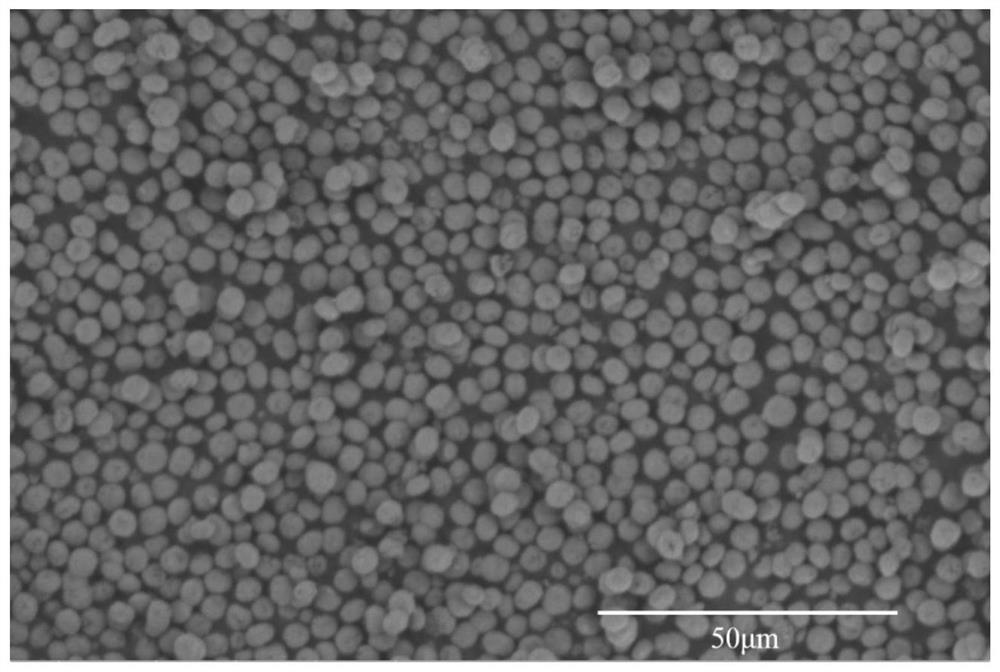

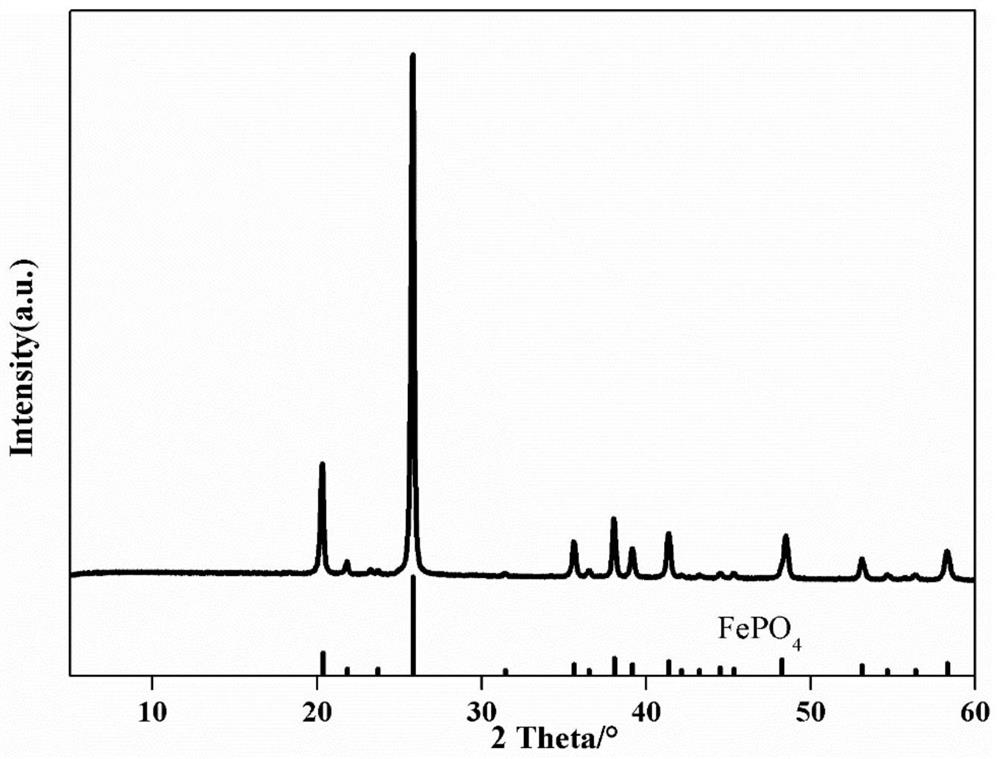

[0051] The preparation method of the battery grade iron phosphate of the present embodiment specifically comprises the following steps:

[0052] (1) 50kg of ferric phosphate dihydrate waste was roasted at 350°C for 3h to remove the crystal water. The roasted material was about 40kg. At 200rpm, the material was put into a sulfuric acid solution kettle with 270L and 1.5mol / L and stirred. Heat to 50°C to dissolve for about 5 hours, then let it stand still, use a precision filter to filter out the filter residue and transfer it to a storage tank to obtain Fe-containing 3+ and PO4 3- The solution, the content of iron and phosphorus in the detection solution is respectively 39.70g / L, 22.36g / L, Fe:P molar ratio=1:1.016;

[0053] (2) Use 10L deionized water as the base solution, which will contain Fe 3+ and PO4 3- The solution and NaOH are injected into the reactor from the bottom of the reactor in parallel at a feeding speed of 7:1, and are fully stirred at a stirring speed of 100...

Embodiment 2

[0061] The preparation method of the battery grade iron phosphate of the present embodiment specifically comprises the following steps:

[0062] (1) 50kg of ferric phosphate dihydrate waste was roasted at 350°C for 3h to remove the crystal water. The roasted material was about 40kg. At 200rpm, the material was put into a 340L, 1.2mol / L sulfuric acid solution tank and stirred. Heat to 50°C to dissolve for about 5 hours, then let it stand still, use a precision filter to filter out the filter residue and transfer it to a storage tank to obtain Fe-containing 3+ and PO4 3- solution, the content of iron and phosphorus in the detection solution is respectively 41.05g / L, 23.55g / L, Fe:P molar ratio=1:1.035;

[0063] (2) 10L deionized water is used as the bottom liquid, which will contain Fe 3+ and PO4 3- The solution and NaOH are injected into the reactor from the bottom of the reactor in parallel at a feed rate of 9:1, and are fully stirred at a stirring speed of 100rpm. The feed ...

Embodiment 3

[0072] The preparation method of the battery grade iron phosphate of the present embodiment specifically comprises the following steps:

[0073] (1) 50kg of ferric phosphate dihydrate waste was roasted at 350°C for 3h to remove the crystal water. The roasted material was about 40kg. At 200rpm, the material was put into a 340L, 1.2mol / L sulfuric acid solution tank and stirred. Heat to 40°C and dissolve for about 5 hours, then let it stand still, use a precision filter to filter out the filter residue and transfer it to a storage tank to obtain Fe-containing 3+ and PO4 3- solution, the content of iron and phosphorus in the detection solution is respectively 41.74g / L, 24.26g / L, Fe:P molar ratio=1:1.048;

[0074] (2) 10L deionized water is used as the bottom liquid, which will contain Fe 3+ and PO4 3- The solution and NaOH are injected into the reactor from the bottom of the reactor in parallel at a feed rate of 8:1, and are fully stirred at a stirring speed of 100rpm. The feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com