Electric vehicle tire pressure monitoring method and system

A technology for tire pressure monitoring and electric vehicles, applied in tire measurement, vehicle parts, tire parts, etc., can solve problems such as poor user experience, difficulty in popularization, and low precision, so as to improve safety, increase accuracy, and reduce errors The effect of rate of return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this embodiment, the method for monitoring the tire pressure of an electric vehicle specifically includes:

[0025] The wheel speed signal of the front wheel of the electric vehicle is obtained through the wheel speed sensor installed on the front wheel of the electric vehicle, and the wheel speed signal of the rear wheel of the electric vehicle is obtained through the wheel speed sensor installed on the rear wheel of the electric vehicle.

[0026] The wheel speed signals of the front wheels of the electric vehicle and the wheel speed signals of the rear wheels of the electric vehicle are transmitted to the processing unit.

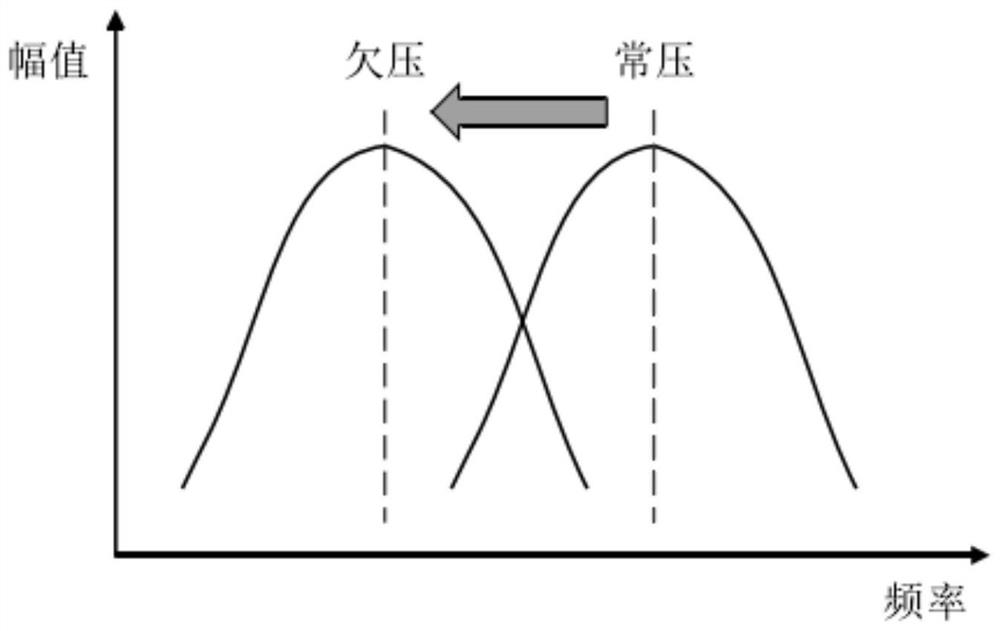

[0027] The signal processing unit processes the received wheel speed signal based on the frequency domain method and the wheel speed comparison method, and judges whether the tire pressure of the front and rear wheels of the electric vehicle is normal.

[0028] Specifically, in this embodiment, the wheel speed sensor installed on the rear wheel ...

Embodiment 2

[0037] This embodiment discloses an electric vehicle tire pressure monitoring system applying the electric vehicle tire pressure monitoring method provided in the first embodiment above. The system includes: a wheel speed sensor installed on the front wheel of the electric vehicle, a wheel speed sensor installed on the rear wheel, and Processing unit; the wheel speed sensor installed on the front wheel of the electric vehicle is used to obtain the wheel speed signal of the front wheel of the electric vehicle; the wheel speed sensor installed on the rear wheel of the electric vehicle is used to obtain the wheel speed signal of the rear wheel of the electric vehicle The processing unit is used to process the received wheel speed signal based on the frequency domain method and the wheel speed comparison method, and judge whether the tire pressure of the front and rear wheels of the electric vehicle is normal.

[0038]Specifically, in this embodiment, the wheel speed sensor install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com