Glass cover plate circumferential polishing mechanism and circumferential polishing equipment

A cover plate circumference and glass technology, which is applied in the field of glass cover plate circumference throwing mechanism and circumference throwing equipment, can solve the problems of inability to remove debris and slag, limited effect, heat accumulation of driving motor, etc., so as to improve the polishing effect and prevent static electricity. The effect of setting precipitation and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

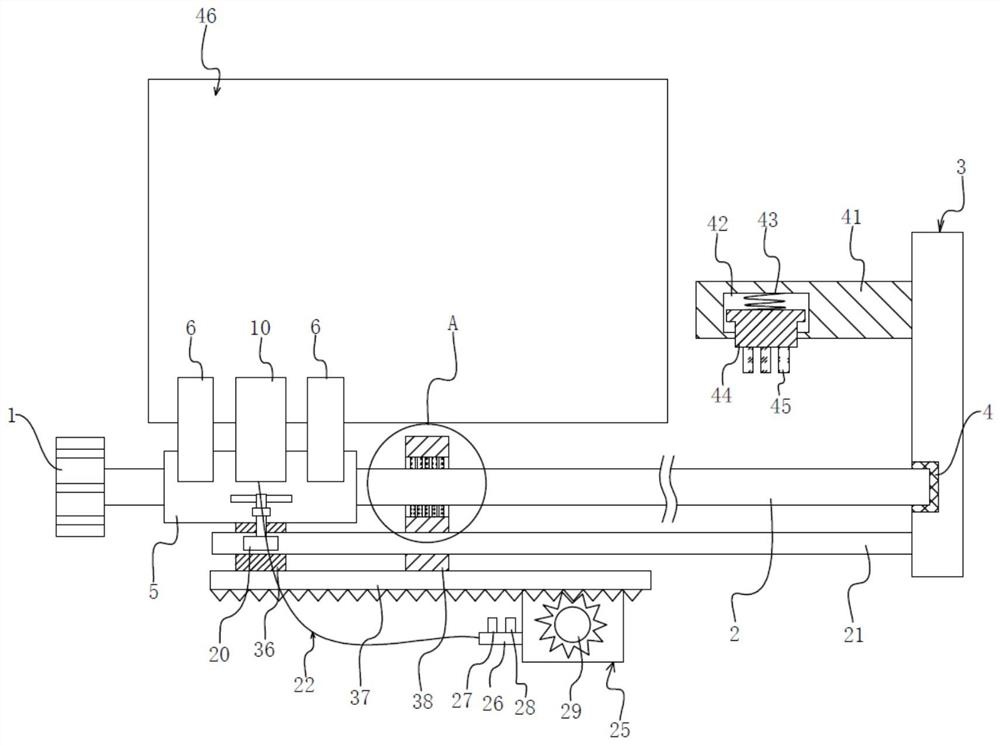

[0034] see Figure 1 to Figure 5 , the present invention provides a technical solution:

[0035] A weekly throwing mechanism for a glass cover, comprising:

[0036] A rotary motor 1, the output end of the rotary motor 1 is fixedly provided with a screw rod 2, the end of the screw rod 2 away from the rotary motor 1 is hingedly arranged in the side plate 3, and a nut block 5 is movable on the screw rod 2, when the rotary motor 1 starts It will drive the screw rod 2 to rotate, and then make the nut block 5 move along the screw rod 2;

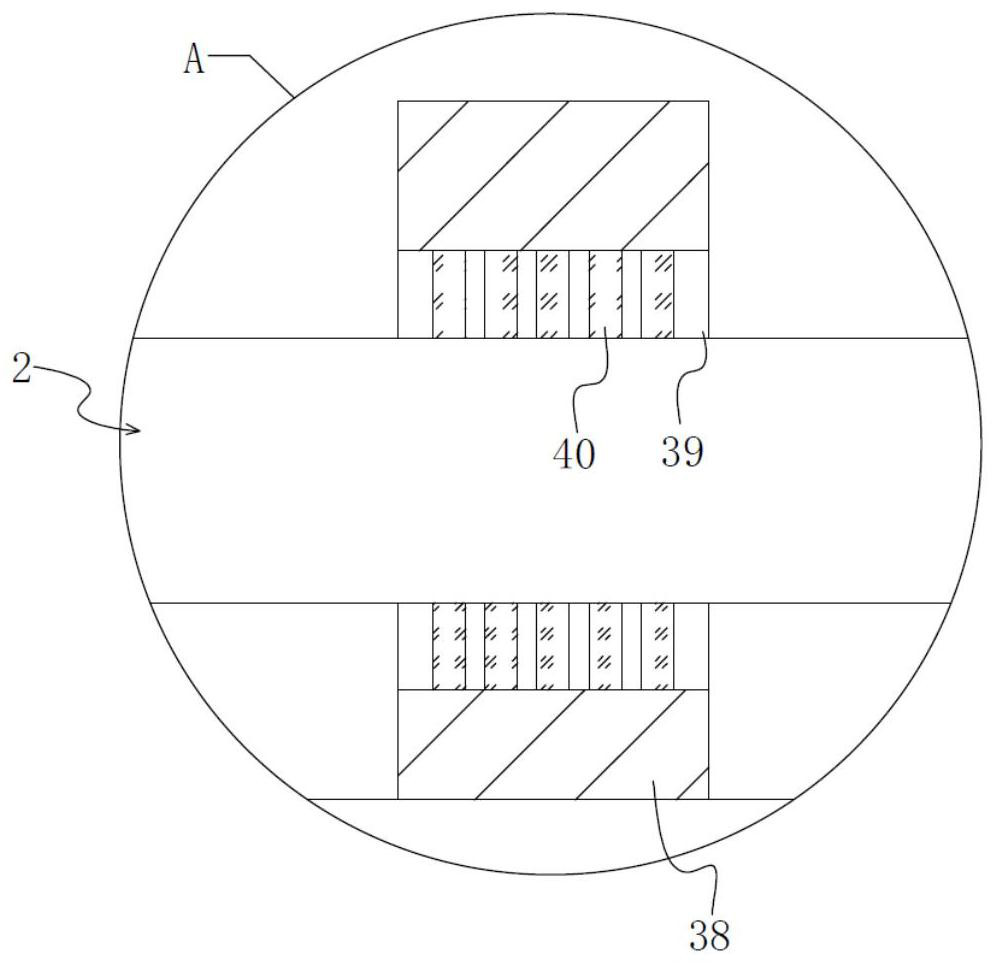

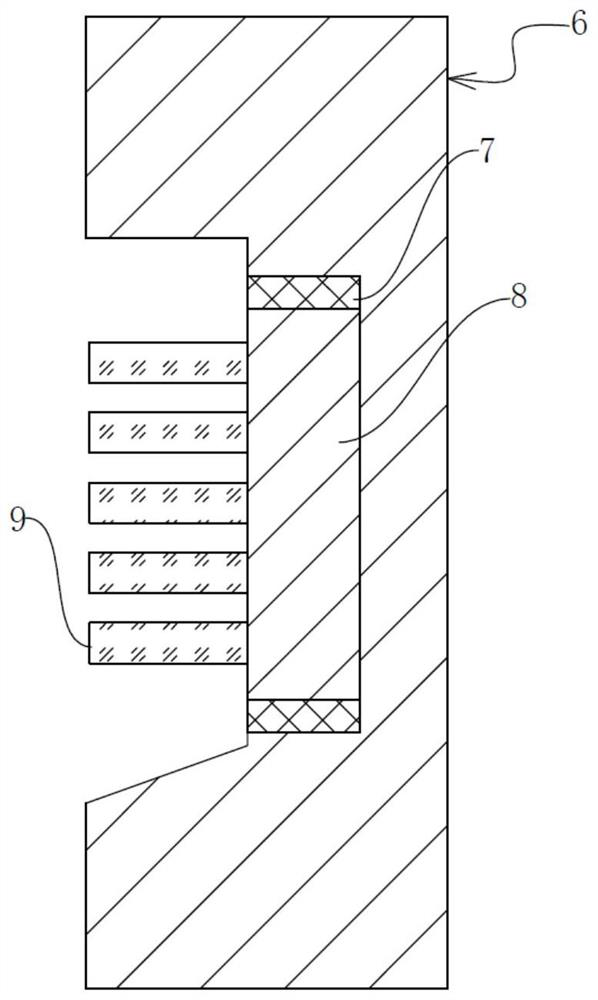

[0037] The dust removal block 6 is fixedly arranged on the nut block 5, and the ring bearing 7 is embedded in the dust removal block 6, and the circular bottom plate 8 is hingedly arranged in the ring bearing 7, and the glass is fixedly arranged on the circular bottom plate 8. Cover plate cleaning brush 9 is used to clean the periphery of the glass cover plate 46. When cleaning, the circular bottom plate 8 can rotate in the ring bearing 7, thereb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com