Method for Eliminating Oil Spots on Thin Nickel Strips

A technology for nickel strips and oil spots, which is applied in the field of eliminating oil spots on thin nickel strips, can solve the problems of surface quality, yellow oil spots on nickel strips, and increase production costs, so as to prevent oxidation and air absorption, reduce costs, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

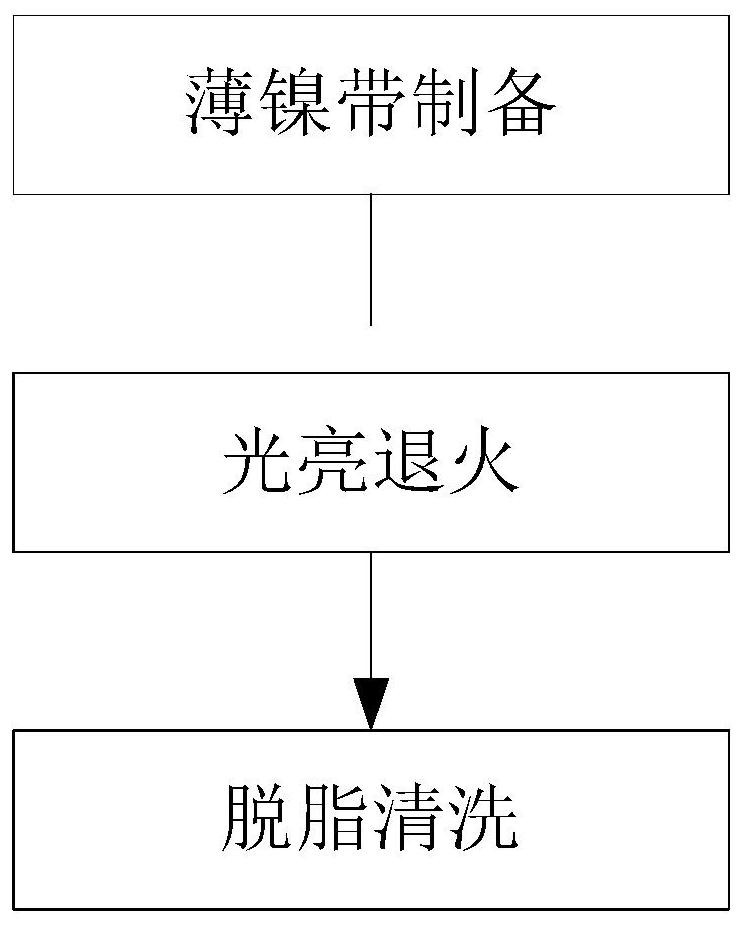

Method used

Image

Examples

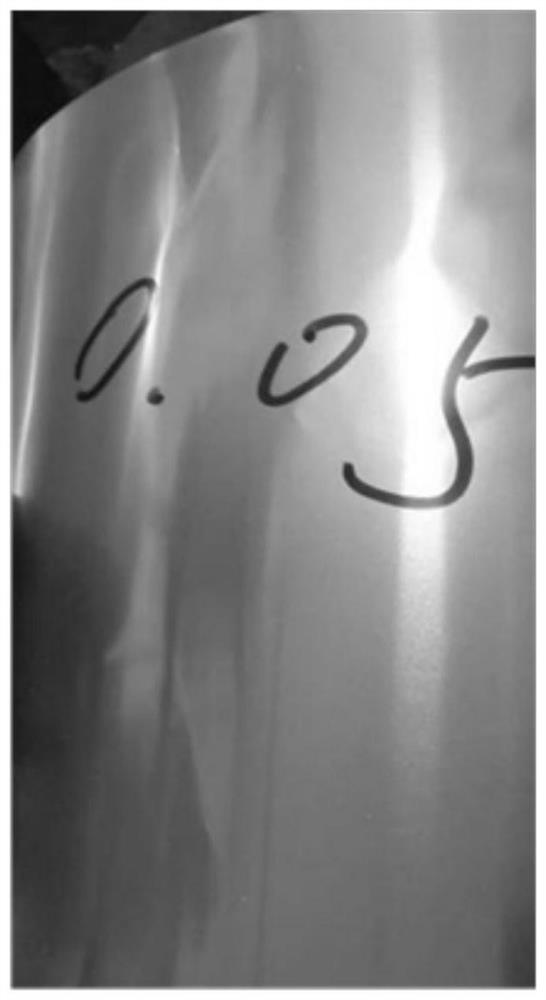

Embodiment 1

[0025]The raw material is 5.3mm thickness N6 hot-rolled slab, rolled 2.0mm, 0.6mm, 0.2mm, 0.05mm thickness in four passes in turn; during each time, the cold-rolled plate is put into a bright annealing furnace for offline annealing treatment, the annealing temperature is 630 °C, and the heat preservation is 20min; the hydrogen is filled into the high-temperature inner tank as a protective gas, the protective gas enters from the outlet end, the inlet end is discharged, the front and rear heating areas are 1500mm length, the temperature set by the inlet heating area is 600 °C, and the temperature of the middle heating zone is 630 °C; the charge of the protective gas is controlled, so that the reading of the flow device is 4m 3 / h, observe the outlet combustion flame, its height must be greater than 300mm, the furnace configuration of the jet air duct supporting the strong circulation system, the heated atmosphere through the jet air duct to the surface of the thin nickel belt, to ac...

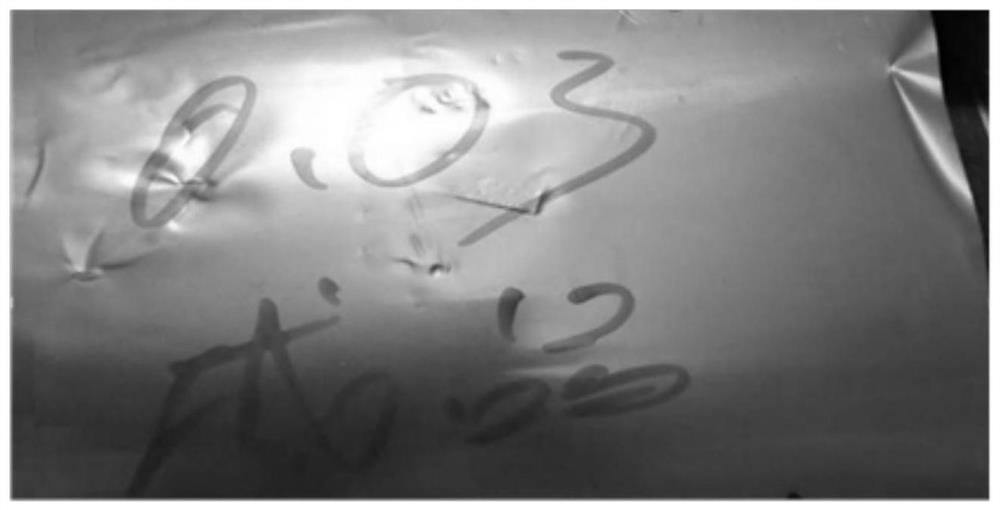

Embodiment 2

[0027] The raw material is 5.5mm thickness N6 hot-rolled slab, rolled in four times in turn 2.0mm, 0.5mm, 0.15mm, 0.03mm thickness; during each time, the cold-rolled plate is put into the bright annealing furnace for offline annealing treatment, the annealing temperature is 650 °C, the insulation is 15min; the hydrogen is filled into the high temperature inner tank as a protective gas, the protective gas enters from the outlet end, the inlet end is discharged, the front and rear heating areas are 1500mm length, the temperature set in the inlet heating area is 610 °C, and the temperature of the middle heating zone is 650 °C; the amount of control protective gas is charged, so that the reading of the flow rate is 4.5 m 3 / h, observe the outlet combustion flame, its height must be greater than 300mm, the furnace configuration of the jet air duct supporting the strong circulation system, the heated atmosphere through the jet air duct to the surface of the thin nickel belt, to achieve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com