A kind of preparation method of chloranil

A technology of tetrachlorobenzoquinone and tetrachlorohydroquinone, which is applied in the preparation of quinone oxide, organic chemistry, etc., can solve the problems of low product purity and yield, unsuitable for industrialized production, long reaction time, etc. The effect of short reaction route and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a kind of preparation method of chloranil, comprising the following steps:

[0026] Chloroquinone and glacial acetic acid are mixed, and nitric acid or chlorine gas is used as an oxidizing agent to carry out oxidation reaction to obtain chlorobenzoquinone; when the oxidizing agent is chlorine gas, the oxidation reaction is carried out under the condition of the presence of a catalyst.

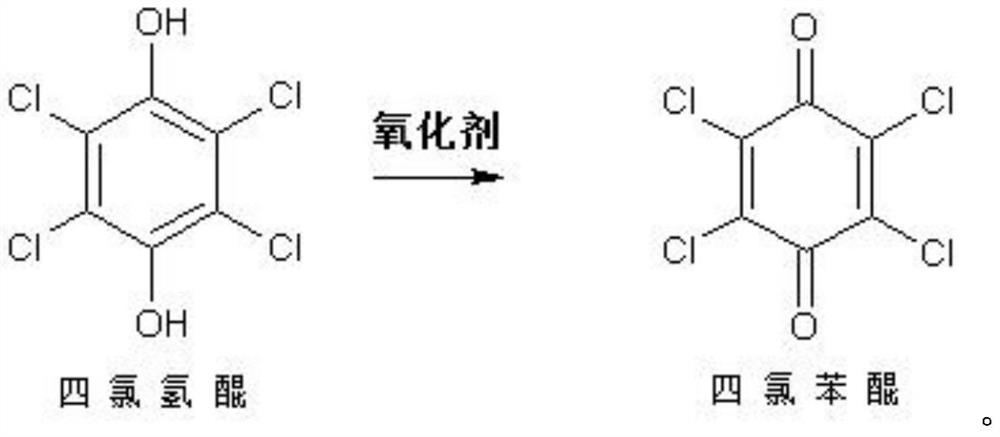

[0027] The present invention uses glacial acetic acid as a solvent and nitric acid or chlorine as an oxidizing agent to oxidize tetrachloroquine to obtain tetrachlorobenzoquinone. The reaction formula is as follows:

[0028]

[0029] The preparation method of chloranil provided by the present invention will be described in detail below according to the different types of oxidants.

[0030] In the present invention, when the oxidant is nitric acid, specifically, chloranil and glacial acetic acid are mixed, and an oxidation reaction (referred to as the first oxida...

Embodiment 1

[0040] Mix 50g of tetrachlorohydroquinone with 250mL of glacial acetic acid, control the temperature at 10°C, add dropwise 10mL of nitric acid with a concentration of 98wt%, and finish the dropwise addition in 30 minutes, stir and react at 10°C for 1 hour, and monitor the reaction by thin-layer chromatography to complete; The obtained product system was filtered, the obtained filter cake was washed to neutrality, and dried at 60° C. for 10 h to obtain 49.1 g of chlorobenzoquinone with a product purity of 99.2% and a yield of 98.2%.

Embodiment 2

[0042] Mix 50g of tetrachlorohydroquinone with 500mL of glacial acetic acid, control the temperature at 20°C, add 25mL of nitric acid with a concentration of 70wt% dropwise, complete the dropwise addition in 45min, stir and react at 20°C for 0.5h, and monitor the reaction by thin-layer chromatography The obtained product system was filtered, the obtained filter cake was washed to neutrality, and dried at 60° C. for 10 hours to obtain 49.2 g of chloranil, the product purity was 99.1%, and the yield was 98.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com