Method for reducing dibutyl phthalate

A technology for dibutyl phthalate and reduction, which is applied in the field of reduction of dibutyl phthalate, can solve the problems of large-scale application of secondary pollution, insufficient degradation, slow process and the like, so as to reduce the toxic effect of DBP , Environmentally friendly and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] The present invention provides the following experiments to verify the effect of low-temperature plasma on reducing DBP.

[0046] 1. Method:

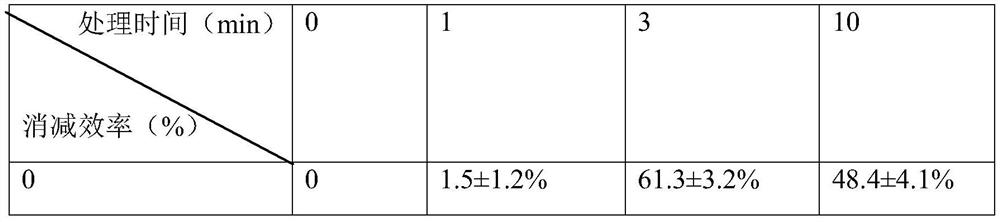

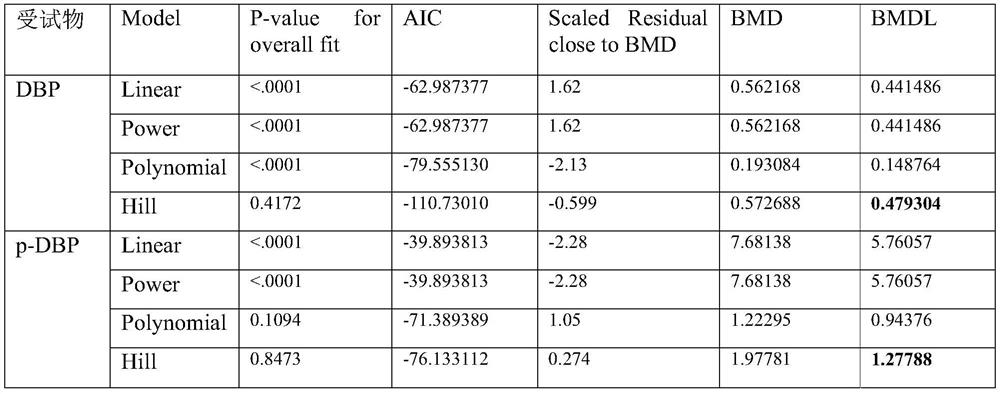

[0047] DBP was treated with low-temperature plasma, and the treatment solution was subjected to isotope dilution liquid chromatography-tandem mass spectrometry (LMS) to detect the elimination efficiency, and the treatment solution was subjected to zebrafish acute embryo experiment (FET) to determine the biological effect.

[0048] 2. Materials and Reagents

[0049] Plasma generation device, DBP samples, standard products, plates, centrifuge tubes, water for sterilization, zebrafish breeding system (Beijing Aisheng Technology Co., Ltd.), etc.

[0050] 3. Experimental steps:

[0051] (1) Dosing

[0052] DBP, 1g / ml, add ethanol to dissolve to 0.5g / ml, add 1% BSA to form nanoemulsion, dilute to 0.1mg / ml with ultrapure water, and use for plasma treatment;

[0053] (2) Plasma treatment

[0054] The power supply used in this method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com