Double-cathode structure and lithium-oxygen battery prepared from double-cathode structure

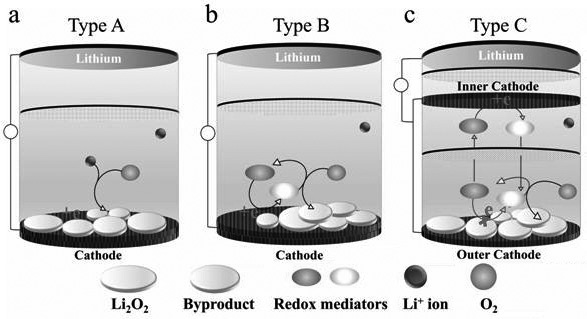

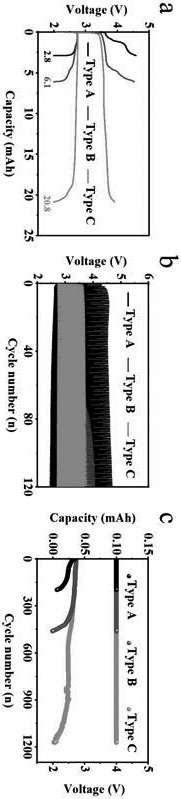

A dual-cathode and cathode technology, applied in battery electrodes, structural parts, fuel cell-type half-cells and secondary battery-type half-cells, etc., can solve the problem of increased battery charging potential, deterioration of battery cycle conditions, and positive electron transfer. Limitation and other issues, to achieve the effect of improving cycle life, reducing by-product formation, and reducing charging potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for assembling a lithium-oxygen battery with a double-cathode structure, the process is as follows:

[0043] (1) Preparation of electrolyte: LiTFSI, DBBQ, and TEMPO were dissolved in TEGDME to obtain electrolyte; the concentrations of LiTFSI, DBBQ, and TEMPO in TEGDME were 1 mol / L, 0.05 mol / L, and 0.2 mol / L, respectively;

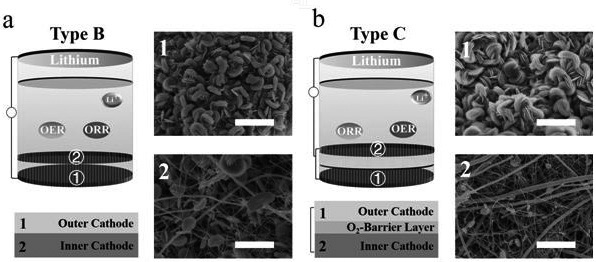

[0044] (2) Preparation of the inner cathode: cut the carbon film into a disc with a diameter of 1.6 cm, and then dry it in a vacuum oven at 80 °C for 24 hours;

[0045] (3) Preparation of the gas barrier layer: the polypropylene film was cut into discs with a diameter of 1.6 cm. The porosity of the original barrier layer was 15% as measured by the scanning electron microscope; at the same time, for comparison, two other discs with a diameter of 1.6 cm were prepared. cm polypropylene membrane discs, two discs were treated by a plasma cleaning machine (power 11W) at room temperature for 5 min and 10 min respectively to obtain gas barrier layer...

Embodiment 2

[0051] A method for assembling a lithium-air battery with a double-cathode structure, the process is as follows:

[0052] The difference from Example 1 is that the gas atmosphere in step (7) is air with a humidity of 25%. The production process of the battery is as follows: assemble the above-mentioned single-cathode lithium-oxygen battery and double-cathode lithium-oxygen battery in an argon-filled glove box, package, and then transfer the battery to an air atmosphere with a humidity of 25%, let it stand for four hours, and seal it , and tested in a constant temperature oven at a temperature of 30°C.

Embodiment 3

[0054] A preparation method of a conventional lithium-oxygen battery, the process is as follows:

[0055] The difference from Example 1 lies in the preparation of the electrolyte in step (1): dissolving LiTFSI in TEGDME to obtain an electrolyte; the concentration of LiTFSI is 1 mol / L.

[0056] The difference from Example 1 is that there is no PSS-Li / GO-Li / GF separator and no gas barrier layer in step (6). That is, the assembly sequence of a conventional lithium-oxygen battery is a lithium sheet, a glass fiber separator soaked in 90 μL of the above-mentioned LiTFSI electrolyte, an inner cathode, and an outer cathode.

[0057] To study the discharge electrodes after cycling, the cells were disassembled in an Ar-filled glove box. Carefully remove the electrode and immerse it in ethylene glycol dimethyl ether (DME) for about 6 h. The dipping process is then repeated several times to completely remove the electrolyte. Thereafter, the electrodes were placed in a vacuum chamber to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com